Description:

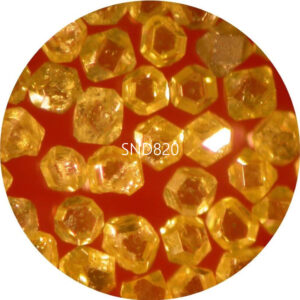

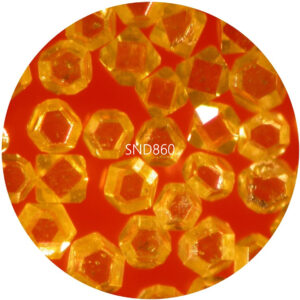

SND890 Saw Grit Diamond is meticulously engineered with a precision-formed cube-octahedron crystal structure, characterized by uniform edge angles (109.5° between adjacent faces) and minimal internal inclusions. This ensures exceptional structural integrity, enhanced by its industry-leading thermal stability. SND890 maintains its hardness (>90 HRC) and cutting efficiency, even when exposed to sustained temperatures of up to 1,200°C—an essential feature for high-friction applications, such as continuous hard rock drilling or deep mining operations.

Designed for professional-grade diamond tools, SND890 significantly improves the performance of blades, core bits, and diamond wires by reducing thermal degradation during extended use. This results in a 30-40% increase in tool life compared to standard grades, fewer interruptions for replacements, and consistent material removal rates that are up to 20% higher than mid-tier alternatives when cutting tough materials like granite, basalt, and reinforced concrete.

Available Grit Sizes: 20/25, 25/30, 30/35, 35/40, 40/45, 45/50 mesh (particle size range: 0.425mm – 1.00mm), with tight tolerance control (±5% of nominal size) for uniform tool bonding and predictable performance.

FAQ:

- Q1: What industries benefit most from SND890 Saw Grit Diamond?

A: SND890 is a top choice for heavy-duty industries requiring consistent performance under extreme conditions, including deep mining (for ore extraction), large-scale construction (such as tunneling and foundation drilling), and geological exploration (hard rock sampling). Its thermal stability also makes it highly valuable in specialized sectors like refractory material processing. - Q2: Can SND890 be used for drilling in hard rock?

A: Yes, SND890 is particularly suited for drilling through hard rock formations (Mohs hardness 7-9), such as granite, quartzite, and gneiss. Its combination of high compressive strength (>20 GPa), low thermal expansion coefficient (1.1×10⁻⁶/°C), and resistance to thermal shock ensures that it maintains cutting sharpness even during extended drilling sessions, reducing bit wear and lowering operational costs. - Q3: How does SND890’s crystal structure impact tool performance?

A: The regular cube-octahedron shape of SND890 ensures uniform load distribution across the diamond surface during cutting, minimizing stress concentrations that can lead to premature fracturing. This structure also promotes consistent abrasion, resulting in smoother cuts and reduced material waste compared to irregularly shaped grits. - Q4: Is SND890 compatible with standard tool manufacturing processes?

A: Yes, SND890 integrates seamlessly with common bonding systems used in professional tool production, including metal matrix, resin, and electroplated bonds. This ensures strong adhesion and reliable performance across diverse manufacturing workflows.

Connect to: