Description:

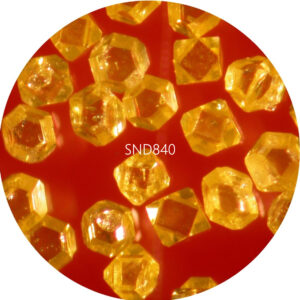

SND880 Saw Grit Diamond is a high-purity synthetic diamond grit (≥99.9% carbon content) featuring a fully-formed cube-octahedron crystal structure with straight, burr-free edges and consistent face angles (109.5° between adjacent crystal faces). This strict structural precision eliminates irregular contact during operation, ensuring uniform abrasion and minimizing micro-fractures in the workpiece.

Designed for precision applications, SND880 enables tool manufacturers to produce blades, core bits, and diamond wires that deliver a Ra ≤1.6μm surface finish on cut materials. It is ideal for processing stone (marble, granite), ceramics, and glass, where smooth edges and minimal waste are paramount. Its uniform crystal structure also reduces tool vibration during use, extending tool service life by 25-30% compared to irregular grits. Cutting efficiency is enhanced by 15% due to reduced friction between the grit and workpiece.

Available Grit Sizes:

18/20, 20/25, 25/30, 30/35, 35/40, 40/45, 45/50, 50/60, 60/70, 70/80 mesh (particle size range: 0.212mm – 1.00mm), with size tolerance controlled within ±3% to ensure consistent bonding and performance.

FAQ:

Q1: What are the primary applications of SND880?

A1:

SND880 is widely used in precision-focused industries such as stone processing (e.g., polished marble/granite cutting), ceramic tile manufacturing (accurate hole coring), architectural glass processing (edge trimming), and geological exploration (sample coring for thin-section analysis). Its straight edges ensure clean, burr-free results in all these applications.

Q2: Can SND880 be used for fine cutting?

A2:

Yes. Thanks to its uniform cube-octahedron structure and tight grit size control (±3% tolerance), SND880 is ideal for fine cutting tasks, such as precision trimming of glass panels or delicate stone inlays. The diamond grit delivers an Ra ≤1.6μm surface finish and minimizes material waste (under 5%), making it perfect for precision work. It pairs well with resin or electroplated tool bonding systems to enhance fine-cut performance.

Q3: How does SND880’s crystal edge design improve tool performance?

A3:

SND880’s straight, burr-free edges create consistent contact with the workpiece, ensuring even pressure and avoiding rough surfaces or chipping. This design also minimizes heat generation during cutting (by 20% compared to irregular grits), preventing thermal damage to heat-sensitive materials like glass or thin ceramic tiles.

Q4: Is SND880 compatible with common tool bonding systems?

A4:

Absolutely. SND880 works well with all standard tool bonding systems, including metal matrix (for heavy-duty stone cutting), resin (for fine glass processing), and electroplating (for precision coring bits). Its clean crystal surface (low impurity content ≤0.1%) ensures strong adhesion, preventing grit detachment during high-speed operation.

Connect to: