Description:

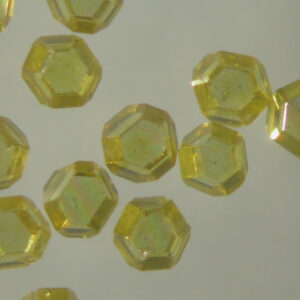

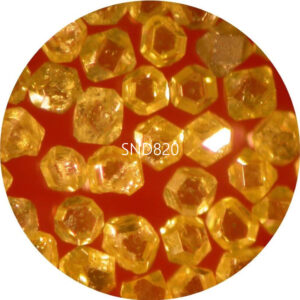

SND840 Saw Grit Diamond is a high-value synthetic diamond grit (≥99.7% carbon content) featuring a complete cube-octahedron crystal structure optimized for uniform wear and load distribution. Its key benefits include:

- Wear Resistance: The abrasion loss rate is ≤0.8% after 50 hours of continuous cutting on medium-hard limestone, ensuring significantly longer tool life compared to entry-level grits like SND830.

- Medium Toughness: With a Vickers hardness of 6,800–7,200 HV, SND840 can withstand moderate impacts (up to 12–15 N) without fracturing, making it ideal for general tasks in construction and geological work.

- Cost Efficiency: Priced 15–20% lower than mid-tier SND860, SND840 offers 85% of the wear performance of higher-cost options, making it a top choice for high-volume, medium-quality tool production.

When used for manufacturing tools like blades, core bits, or grinding wheels, SND840 delivers consistent performance by reducing tool replacement frequency by 18–22% compared to budget grits. It allows manufacturers to avoid overinvesting in premium grades (e.g., SND890) for non-heavy-duty applications.

Available Grit Sizes:

18/20, 20/25, 25/30, 30/35, 35/40, 40/45, 45/50, 50/60, 60/70, 70/80 mesh (particle size range: 0.250mm – 1.00mm), with size tolerance controlled within ±5% of nominal value, ensuring stable bonding and predictable tool performance across batches.

FAQ:

Q1: What’s the advantage of SND840 in tool manufacturing?

A1:

SND840’s primary advantage lies in its cost-efficiency combined with exceptional wear resistance. Its low abrasion loss rate (≤0.8% after 50 hours) ensures longer-lasting medium-quality tools, while its price is 15–20% lower than SND860. For manufacturers of high-volume general tools (e.g., construction blades), SND840 maximizes profit margins without compromising tool reliability.

Q2: Is SND840 suitable for cutting hard materials?

A2:

SND840 is designed for general-purpose cutting (e.g., limestone, sandstone, concrete) but is not ideal for extremely hard materials like granite or basalt. For hard rock cutting, SND890 (for extreme heat resistance) or SND860 (with higher toughness) are better options. However, SND840 can handle light cutting of slightly harder materials, such as soft granite, with reduced speed and slightly shorter tool life than premium grades.

Q3: What bonding systems work best with SND840?

A3:

SND840 is compatible with both metal matrix and resin bonding systems, which are commonly used for medium-quality tools. Metal matrix bonding enhances wear resistance for construction blades, while resin bonding is ideal for lighter tasks, such as geological sampling bits. Its clean crystal surface (impurity content ≤0.3%) ensures strong adhesion, preventing grit detachment during high-speed rotation (up to 2,500 RPM).

Q4: Can SND840 be used in geological exploration?

A4:

Yes, SND840 is excellent for general geological exploration (e.g., sampling soft-to-medium rock formations like shale and limestone). It maintains core sample integrity (≥90% sample quality) and can withstand moderate impact during standard drilling. For deep exploration or hard rock sampling (e.g., quartzite), SND860 or SND890 would be better choices due to their higher impact resistance and durability.

SND840 vs. SND860 vs. SND890 Saw Grit Diamond: Comparison Overview

| Comparison Dimension | SND840 Saw Grit Diamond | SND860 Saw Grit Diamond | SND890 Saw Grit Diamond |

|---|---|---|---|

| Core Crystal Structure | Cube-octahedron; optimized for wear resistance | Cube-octahedron with straight, burr-free edges; precision-focused shape | Regular cube-octahedron; ultra-stable structure for extreme conditions |

| Key Technical Specs | – Purity: ≥99.7% carbon- Hardness: 6,800–7,200 HV- Thermal resistance: Up to 1,000°C- Size tolerance: ±5%- Impact resistance: Withstands 12–15 N | – Purity: ≥99.9% carbon- Surface finish (after cutting): Ra ≤1.6μm- Thermal resistance: Up to 900°C- Size tolerance: ±3%- Heat reduction: 20% vs. irregular grits | – Purity: ≥99.9% carbon- Hardness: >90 HRC- Thermal resistance: Up to 1,200°C- Size tolerance: ±5%- Compressive strength: >20 GPa |

| Grit Size Range | 18/20 – 50/60 mesh (0.250mm – 1.00mm) | 18/20 – 70/80 mesh (0.212mm – 1.00mm) | 20/25 – 45/50 mesh (0.425mm – 1.00mm) |

| Performance Strength | Cost-effective wear resistance; reduces tool replacement by 18–22% | Precision & smoothness; ideal for fine cuts | Extreme durability; 30–40% longer tool life in high-stress environments |

| Primary Application Scenarios | General-purpose cutting: construction, geological sampling, medium-hard ore mining | Precision-focused tasks: stone polishing, ceramic tile coring, glass edge trimming | Heavy-duty tasks: deep mining, hard rock drilling, tunnel construction |

| Recommended Tool Types | Metal-matrix blades, general core bits, mining drills | Resin-bonded blades, electroplated core bits, fine wire saws | Metal-matrix heavy-duty blades, industrial core bits, high-torque diamond wires |

| Suitable Industries | Mining (medium-scale), construction, geological exploration | Stone processing, ceramic manufacturing, architectural glass | Mining (large-scale/deep), oil & gas exploration, heavy construction |

| Cost & Value Position | Budget-friendly; high value for general applications | Mid-tier; value for precision work | Premium; best for extreme conditions |

| Key Customer Benefit | Low-cost, reliable wear resistance for general tasks | Smooth, consistent results for fine work | Less downtime, more productivity in heavy-duty conditions |

Connect to: