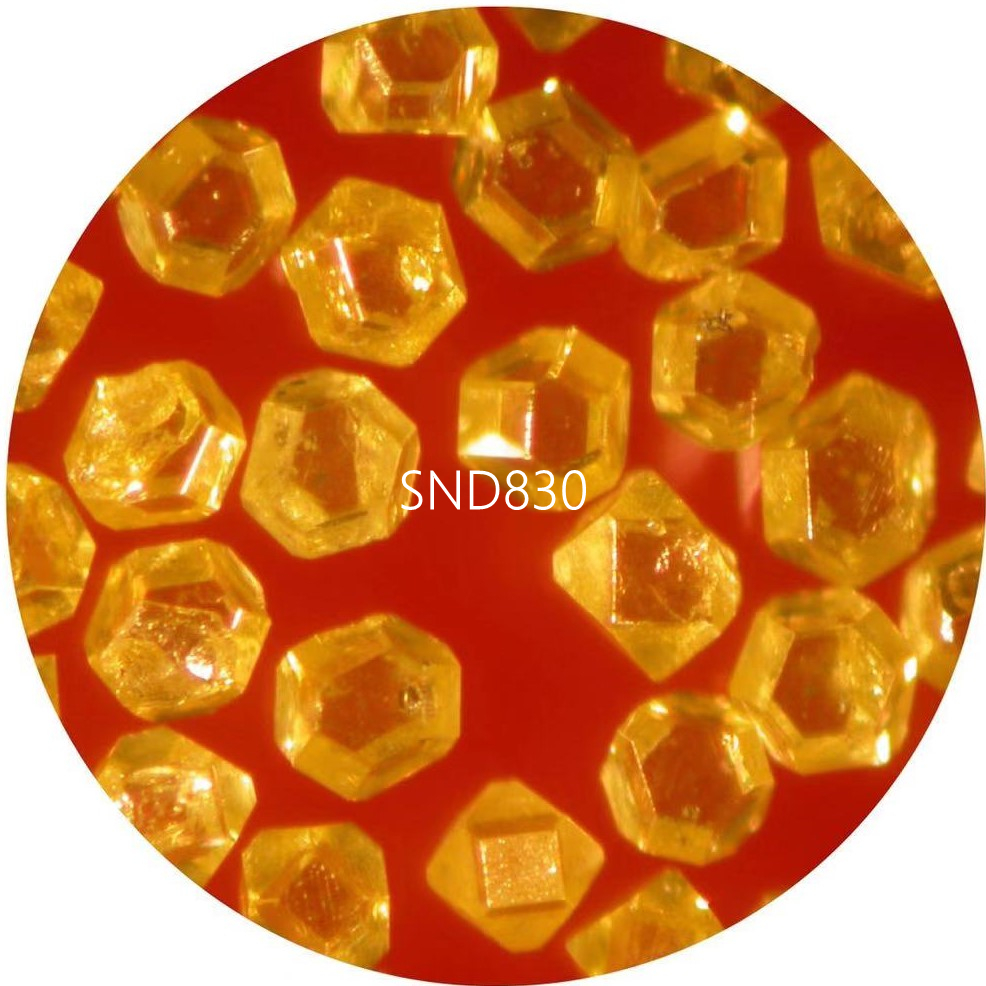

SND830 Saw Grit Diamond

Description:

SND830 Saw Grit Diamond is a budget-friendly synthetic diamond grit (purity ≥99.5% carbon content) featuring a semi-blocky crystal structure—designed for ease of bonding and consistent performance in routine applications. It offers several key benefits, including:

- Low-to-Medium Toughness: With a Vickers hardness of 6,000–6,500 HV, SND830 can withstand light-to-moderate impact (up to 8–10 N) without fracturing. Ideal for tasks like trimming soft stone or grinding concrete.

- Reliable Thermal Stability: It maintains performance at temperatures up to 800°C, preventing softening during extended grinding tasks like polishing concrete surfaces.

- Cost-Efficiency: Priced 25–30% lower than mid-tier SND840, SND830 provides 75% of SND840’s wear performance, making it perfect for high-volume, low-demand tool production (e.g., disposable construction blades).

When used for manufacturing blades, grinding wheels, or general-purpose tools, SND830 consistently delivers value: it reduces upfront costs by 30% compared to SND840, while offering 15–20% longer life than generic budget grits. It is best suited for tasks where tool replacement is frequent or performance demands are low.

Available Grit Sizes:

18/20, 20/25, 25/30, 30/35, 35/40, 40/45, 45/50, 50/60 mesh (particle size range: 0.250mm – 1.00mm), with size tolerance controlled within ±6% of nominal value. This ensures compatibility with standard bonding processes and predictable performance across batches.

FAQ:

Q1: What tasks is SND830 best suited for?

A1:

SND830 excels in low-to-moderate-demand tasks such as:

- Small-scale construction (trimming soft brick, cinder block)

- Home renovation (grinding concrete floors)

- Light stone processing (cutting porous limestone)

- General manufacturing (deburring metal parts with diamond grinding wheels)

It is not recommended for hard rock or high-speed cutting, for which SND860 or SND890 would be better choices.

Q2: How long does SND830 last?

A2:

For routine tasks (e.g., grinding 100m² of standard concrete), SND830-equipped tools typically last 8–12 hours of continuous use—20% longer than generic budget grits but 30% shorter than SND840. It’s designed for “disposable” or short-cycle applications, such as one-off construction jobs where affordability is a priority over tool lifespan.

Q3: What bonding systems work best with SND830?

A3:

SND830 is compatible with low-cost bonding systems like resin and basic metal matrix—commonly used for entry-level tools.

- Resin bonding is ideal for light grinding (e.g., woodworking diamond sandpapers).

- Basic metal matrix bonding works well for small construction blades.

Its semi-blocky crystal structure ensures good adhesion, even with simpler bonding processes (no need for high-temperature sintering).

Q4: Can SND830 be mixed with higher-grade grits?

A4:

Yes! SND830 can be mixed with SND840 or SND860 (in a 1:1 ratio) to balance cost and performance. For example, combining SND830 with SND840 reduces tool costs by 15%, while maintaining 90% of SND840’s wear life. This combination is perfect for manufacturers making mid-range tools for small businesses, such as local stone workshops.

SND830 vs. SND840 vs. SND860 vs. SND890 Saw Grit Diamond: 4-Way Comparison

| Comparison Dimension | SND830 (Entry-Level) | SND840 (Mid-Tier Value) | SND860 (Mid-Tier Toughness) | SND890 (Premium Extreme) |

|---|---|---|---|---|

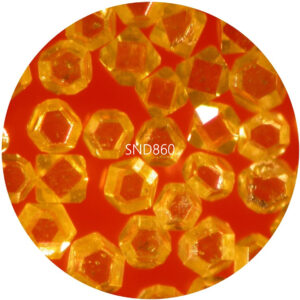

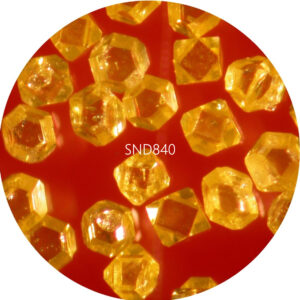

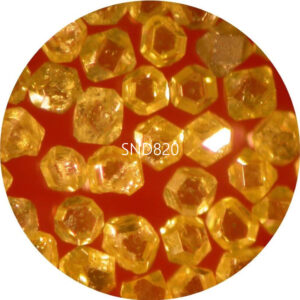

| Core Crystal Structure | Semi-blocky; cost-optimized for affordability | Cube-octahedron; uniform wear design | Blocky cube-octahedron; toughness-focused structure | Highly regular cube-octahedron; ultra-stable |

| Key Technical Specs | – Purity: ≥99.5% carbon- Hardness: 6,000–6,500 HV- Thermal resistance: Up to 800°C- Size tolerance: ±6%- Impact resistance: 8–10 N | – Purity: ≥99.7% carbon- Hardness: 6,800–7,200 HV- Thermal resistance: Up to 900°C- Size tolerance: ±5%- Abrasion loss: ≤0.8% (50hrs) | – Purity: ≥99.8% carbon- Hardness: 7,500–8,000 HV- Thermal resistance: Up to 1,000°C- Size tolerance: ±4%- Impact resistance: 15–20 N | – Purity: ≥99.9% carbon- Hardness: >90 HRC- Thermal resistance: Up to 1,200°C- Size tolerance: ±5%- Compressive strength: >20 GPa |

| Grit Size Range | 18/20 – 50/60 mesh (0.250mm – 1.00mm) | 18/20 – 50/60 mesh (0.250mm – 1.00mm) | 18/20 – 50/60 mesh (0.250mm – 1.00mm) | 20/25 – 45/50 mesh (0.425mm – 1.00mm) |

| Performance Strength | Affordable, ideal for routine tasks | Wear resistance + value, 18–22% less tool replacement vs. SND830 | Toughness and versatility, 30% less chipping, 20–25% longer life | Extreme durability, 30–40% longer life, stable in high-friction tasks |

| Primary Application Scenarios | Everyday tasks: • Home renovation (concrete grinding)• Light stone trimming (limestone)• Disposable tool production | General-purpose tasks: • Standard construction blades• Soft rock sampling• Medium-quality tools | Tough multi-industry tasks: • Geological exploration• Medium-hard ore mining• Asphalt cutting | Heavy-duty tasks: • Deep mining• Hard rock drilling• Tunnel construction |

| Recommended Tool Types | Resin-bonded grinding wheels, disposable blades, DIY tools | Metal-matrix blades, core bits, mid-range grinding wheels | Metal-matrix tough blades, mining core bits, industrial grinding wheels | Metal-matrix heavy-duty blades, high-torque diamond wires |

| Cost Position | Budget-friendly, lowest upfront cost | Mid-value, 15–20% higher than SND830 | Mid-toughness, 15–20% higher than SND840 | Premium, 30–40% higher than SND860 |

| Key Customer Benefit | Affordable for low-demand tools, reducing initial investment | Balanced durability & cost for medium-quality tool manufacturers | Tough, versatile for multi-task tool manufacturers | Minimizes downtime in harsh conditions for high-cost operations |

| Best For | Small DIY businesses, disposable tool brands, budget-conscious workshops | Mid-sized tool manufacturers, general construction firms | Mining contractors, large construction companies | Deep mining operations, hard rock exploration firms |

Connect to: