Description:

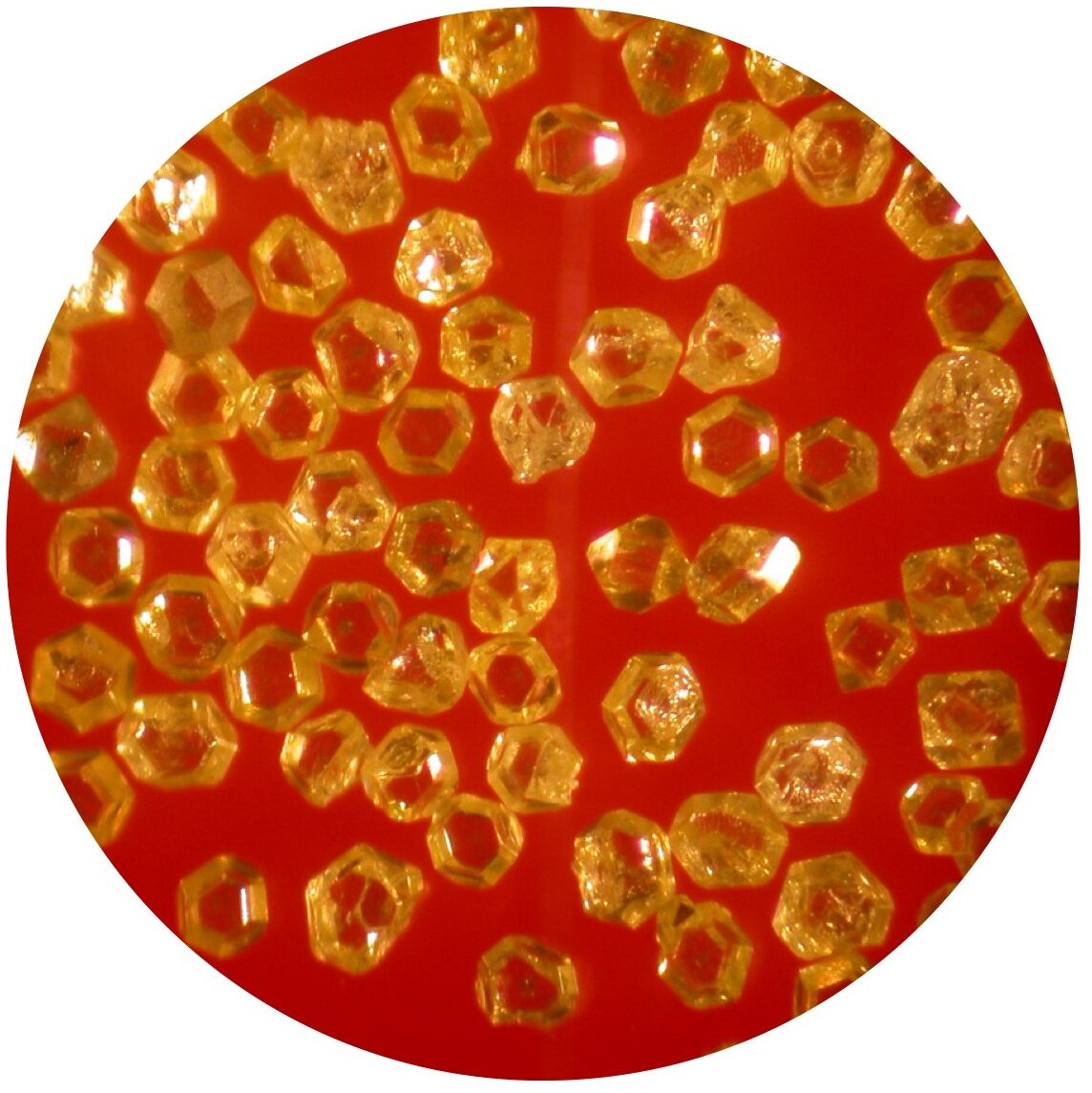

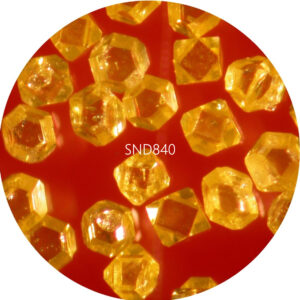

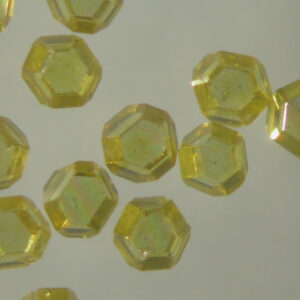

SND815 Saw Grit Diamond is a value-optimized synthetic diamond grit with a purity of ≥99.3% carbon content, featuring a semi-regular granular shape. It is specifically engineered to integrate seamlessly with premium grades like SND840 or SND860 to enhance performance while lowering material costs. The main benefits of using SND815 include:

- Blending Compatibility:

Designed for 1:1 to 1:3 mixing ratios with premium grades (e.g., 50% SND815 + 50% SND840), SND815 boosts material removal efficiency by 12–15% compared to using SND840 alone, without compromising tool life. - Cost Reduction:

Priced 20–25% lower than SND830, SND815 reduces overall tool material costs by 10–18% when blended with premium diamonds. This makes it ideal for high-volume production of medium-quality tools, such as stone-cutting blades. - Basic Performance Stability:

With a Vickers hardness of 5,200–5,800 HV and thermal resistance up to 700°C, SND815 performs reliably under moderate loads in stone and ceramic processing, ensuring consistent durability without premature fracturing. - Improved Grit Distribution:

When blended with higher-grade diamonds like SND860, SND815 fills micro-gaps in tool bonding, improving grit distribution and reducing uneven wear. For example, mixing SND815 with SND860 (1:2 ratio) maintains 90% of SND860’s toughness while lowering material costs by 15%.

Available Grit Sizes:

18/20, 20/25, 25/30, 30/35, 35/40, 40/45, 45/50, 50/60 mesh (particle size range: 0.250mm – 1.00mm), with size tolerance controlled within ±8% of nominal value, ensuring consistent blending with higher-grade grits of matching mesh sizes.

FAQ:

Q1: How should SND815 be blended with higher-grade diamonds?

A: SND815 is best blended with premium grades in the following ratios:

- 1:1 (50% SND815 + 50% SND840): Ideal for standard construction blades. Balances cost and performance, maintaining 85% of SND840’s wear life while cutting costs by 10%.

- 1:2 (33% SND815 + 67% SND860): Prioritizes toughness for medium-hard stone cutting, maintaining 90% of SND860’s impact resistance while cutting costs by 15%.

- 1:3 (25% SND815 + 75% SND890): Suitable for light heavy-duty tasks, such as soft granite cutting. Reduces costs by 8% without compromising high-temperature stability.

Q2: What materials is SND815 suitable for processing?

A: SND815 (when blended) is ideal for processing medium-soft to medium-hard materials, including porous stone (like travertine and limestone), ceramic tiles (both glazed and unglazed), and soda-lime glass (commonly used in architectural panels). It is not recommended for hard rock (such as granite or basalt) or high-temperature applications, for which unblended SND860 or SND890 are more suitable.

Q3: Can SND815 be used alone (without blending)?

A: While it is technically possible to use SND815 on its own, it is not recommended. Using SND815 alone results in shorter tool life (3–5 hours of continuous stone cutting compared to 8–12 hours with SND830) and reduced impact resistance (withstands only 6–8 N). It is most cost-effective when blended with higher-grade diamonds to optimize performance while reducing costs.

Q4: What bonding systems work with blended SND815?

A: Blended SND815 is compatible with both metal matrix and resin bonding systems—the two most common bonding methods for medium-quality tools. Metal matrix bonding enhances durability for stone-cutting blades, while resin bonding is more suitable for lighter ceramic and glass grinding tools. The semi-regular shape of SND815 ensures good adhesion to both systems, preventing grit detachment during high-speed rotation (up to 2,200 RPM).

SND815 vs. SND820 vs. SND830 vs. SND840 vs. SND860 vs. SND890 Saw Grit Diamond: 6-Way Comparison Table

Comparison Dimension | ||||||

Core Crystal Structure | Semi-regular granular; blending-optimized shape | Relatively regular semi-cubic; efficiency-optimized shape | Semi-blocky; cost-optimized shape | Complete cube-octahedron; uniform wear design | Blocky cube-octahedron; toughness-focused structure | Highly regular cube-octahedron; minimal inclusions; ultra-stable |

Key Technical Specs | – Purity: ≥99.3% carbon- Hardness: 5,200–5,800 HV- Thermal resistance: Up to 700°C- Size tolerance: ±8%- Blending ratio range: 1:1 to 1:3 | – Purity: ≥99.4% carbon- Hardness: 5,500–6,000 HV- Thermal resistance: Up to 750°C- Size tolerance: ±7%- MRR: 15–20 cm³/min (soft stone) | – Purity: ≥99.5% carbon- Hardness: 6,000–6,500 HV- Thermal resistance: Up to 800°C- Size tolerance: ±6%- Impact resistance: 8–10 N | – Purity: ≥99.7% carbon- Hardness: 6,800–7,200 HV- Thermal resistance: Up to 900°C- Size tolerance: ±5%- Abrasion loss: ≤0.8% (50hrs) | – Purity: ≥99.8% carbon- Hardness: 7,500–8,000 HV- Thermal resistance: Up to 1,000°C- Size tolerance: ±4%- Impact resistance: 15–20 N | – Purity: ≥99.9% carbon- Hardness: >90 HRC- Thermal resistance: Up to 1,200°C- Size tolerance: ±5%- Compressive strength: >20 GPa |

Grit Size Range | 18/20 – 50/60 mesh (0.250mm – 1.00mm) | 18/20 – 50/60 mesh (0.250mm – 1.00mm) | 18/20 – 50/60 mesh (0.250mm – 1.00mm) | 18/20 – 50/60 mesh (0.250mm – 1.00mm) | 18/20 – 50/60 mesh (0.250mm – 1.00mm) | 20/25 – 45/50 mesh (0.425mm – 1.00mm) |

Performance Strength | Cost reduction via blending: Cuts material costs by 10–18%; boosts efficiency by 12–15% when mixed | Speed for light tasks: 25% faster MRR than SND830; lowest upfront cost | Affordability for routine use: 20% longer life than generic grits; balanced speed/durability | Wear resistance + value: 18–22% less tool replacement vs. SND830; 85% of SND860’s performance | Toughness + versatility: 30% less chipping; 20–25% longer life than SND830 | Extreme durability + heat resistance: 30–40% longer life vs. SND860; stable in high-friction tasks |

Primary Application Scenarios | Blended medium-quality tools: • Stone processing (limestone/travertine)• Ceramic tile cutting• Glass panel trimming• High-volume mid-market tools | Ultra-light, fast tasks: • DIY projects (glass tile cutting)• One-off repairs (soft brick trimming)• Disposable mini-blades | Everyday low-demand tasks: • Home renovation (concrete grinding)• Light stone trimming (limestone)• Low-volume disposable tools | General-purpose medium tasks: • Standard construction blades• Soft-to-medium rock sampling• High-volume medium-quality tools | Tough multi-industry tasks: • Geological exploration (sandstone/quartz)• Medium-hard ore mining• Construction (asphalt cutting) | Heavy-duty high-stress tasks: • Deep mining (hard ore)• Hard rock drilling (granite/basalt)• Tunnel construction |

Recommended Tool Types | Blended metal-matrix/resin blades, mid-tier core bits, bulk stone-cutting tools | Resin-bonded DIY sandpapers, mini handheld blades, disposable craft tools | Resin-bonded grinding wheels, standard disposable blades, small workshop tools | Metal-matrix standard blades, general core bits, mid-range grinding wheels | Metal-matrix tough blades, mining core bits, industrial grinding wheels | Metal-matrix heavy-duty blades, high-torque diamond wires, extreme-condition core bits |

Cost Position | Ultra-budget blending (20–25% lower than SND830) | Ultra-budget light-duty (10–15% lower than SND830) | Budget routine (lowest upfront for repeated use) | Mid-value (15–20% higher than SND830) | Mid-toughness (15–20% higher than SND840) | Premium (30–40% higher than SND860) |

Key Customer Benefit | “Cuts costs without losing performance”—ideal for high-volume mid-market tool brands | “Fast, cheap for one-off tasks”—no overinvestment in infrequent use | “Affordable for high-volume, low-demand tools”—reduces initial investment | “Balances durability and cost”—higher margins for medium-quality tool manufacturers | “One grit for multiple tough tasks”—simplifies inventory; avoids overpaying for premium | “Minimizes downtime in harsh conditions”—reliable for critical, high-cost operations |

Best For | Mid-market tool manufacturers, bulk stone processors, ceramic/glass production lines | Hobbyists, DIY enthusiasts, one-off repair services | Small DIY businesses, budget-conscious workshops, low-volume disposable tool brands | Mid-sized tool manufacturers, general construction firms, standard geology labs | Mining contractors, large construction companies, multi-purpose tool brands | Deep mining operations, hard rock exploration firms, premium tool manufacturers |