What Is Resin Bond Diamond?

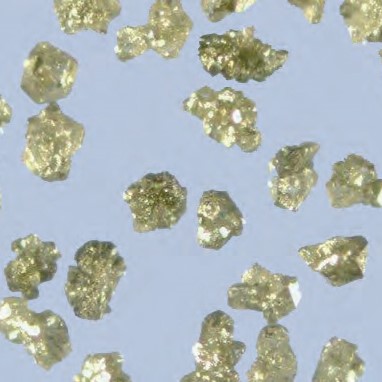

Resin bond diamond is a type of synthetic diamond abrasive specifically designed for use in resin-bonded grinding wheels and tools. Each diamond particle is embedded in a phenolic or polyimide resin matrix, providing a controlled balance between cutting ability and surface finish.

Compared with metal or vitrified bond diamonds, resin bond diamond grains fracture more easily, allowing continuous exposure of sharp cutting edges during grinding. This property enables cooler cutting, lower surface damage, and smoother finishes, especially on hard or brittle materials.

Resin bond diamonds are widely used in precision grinding, lapping, and polishing of tungsten carbide, ceramics, glass, and hard alloys.

Applications of Resin Bond Diamond

Resin bond diamond powders and grits are used in many fine-grinding and finishing operations, including:

- Grinding and polishing of tungsten carbide tools

- Precision machining of ceramics, sapphire, quartz, and glass

- Polishing of PCD, PCBN, and hard coatings

- Mold and die finishing

- Semiconductor wafer lapping

- Optical lens finishing and glass edge grinding

Their self-sharpening friability makes them perfect for high-precision and surface-critical applications.

SinoDiam Resin Bond Diamond Overview

SinoDiam offers a full range of resin bond diamond powders engineered for different friability levels and performance needs under the RVG series (SND-R05, R10, R15, R20).

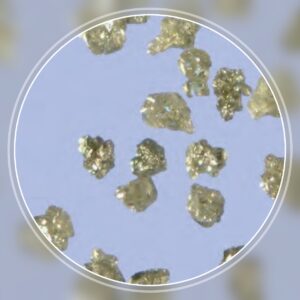

Each grade is optimized for a specific balance of friability, cutting force, and surface finish:

| Product | Type | Key Feature | Typical Application |

|---|---|---|---|

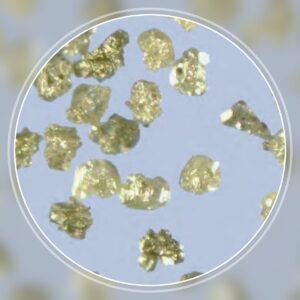

| SND-R05 | Ultra-High Friability | Mirror-finish precision | Mold inserts, optical parts |

| SND-R10 | Semi-Blocky | Cost-effective grinding | Industrial and standard parts |

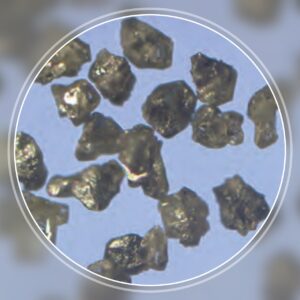

| SND-R15 | Standard Blocky | Balanced cutting & life | Automotive, valves, molds |

| SND-R20 | High Friability | Continuous self-sharpening | Aerospace, medical devices |

Whether you need maximum precision, durability, or cost efficiency, SinoDiam’s RVG series provides consistent quality for all resin-bonded grinding and polishing systems.

10 Hot-Searching FAQs About Resin Bond Diamond

1. What is resin bond diamond used for?

Resin bond diamond is used for fine grinding and polishing of hard materials like tungsten carbide, ceramics, and glass, providing superior surface finishes.

2. What is the difference between resin bond and metal bond diamond?

Resin bond diamonds are softer and more friable, designed for cooler, smoother cutting, while metal bond diamonds are harder and more durable for heavy grinding.

3. What are the advantages of resin bond diamond?

They offer high surface quality, low grinding heat, and excellent self-sharpening, ideal for precision and mirror-finish applications.

4. Which industries use resin bond diamond the most?

Used widely in tool manufacturing, optics, semiconductor, and mold & die industries.

5. What mesh sizes are available for resin bond diamond powder?

Typically 60/70 to 325/400 mesh for grinding wheels, and finer micron sizes for polishing compounds.

6. Can resin bond diamonds be used in polyimide bonds?

Yes. SinoDiam’s RVG series is compatible with both phenolic and polyimide resin bond systems, ensuring versatility and stability.

7. How does friability affect performance?

Higher friability means faster self-renewal of sharp edges, improving cutting efficiency and surface smoothness but reducing tool life slightly.

8. What’s the difference between SND-R05 and SND-R15?

SND-R05 is ultra-high friability for mirror finishing, while SND-R15 offers balanced friability for longer tool life and broader use.

9. How should resin bond diamond powders be stored?

Store in sealed, dry containers away from moisture and extreme temperatures to maintain performance consistency.

10. Why choose SinoDiam resin bond diamond?

SinoDiam provides uniform crystal morphology, controlled friability, and consistent quality, ensuring superior performance and repeatability across production batches.