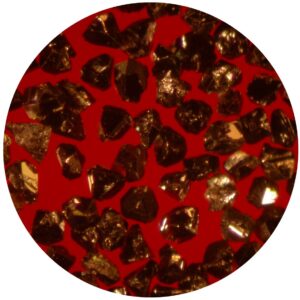

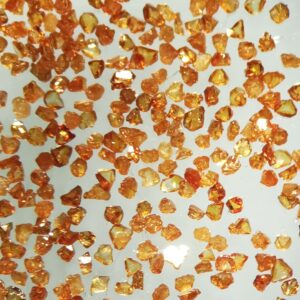

CBN-A10 Amber Irregular CBN – High-Performance Resin Bond CBN for Ferrous Metal Grinding

Product Description

CBN-A10 stands out with its distinct amber color and irregular crystal shape, which ensures tight adhesion in resin bonds and reduces grit shedding by up to 20%. Its medium toughness delivers the ideal balance of durability and self-sharpening, allowing particles to gradually fracture and expose fresh cutting edges—avoiding dulling or “glazing” during continuous grinding.

Available in 50/60, 120/140, and 325/400 mesh, CBN-A10 ensures uniform distribution in resin matrices, critical for consistent grinding performance across different tool sizes and applications. It is specifically engineered for ferrous metals, alloy steels, and carbon steel, providing smooth surface finishes (Ra ≤1.6μm) and extending resin bond tool life by up to 15% compared to standard CBN products.

Key Advantages:

- Resin Bond Compatibility: Irregular particles interlock tightly with resin, minimizing grit shedding and enhancing grinding consistency.

- Self-Sharpening: Medium toughness ensures continuous edge renewal, maintaining high efficiency during long grinding operations (8–10 hours).

- Cost-Effective: Offers an excellent performance-to-price ratio, perfect for mid-tier resin bond applications such as handheld grinding discs, bench wheels, and small workshop tools.

- High Thermal Stability & Efficiency: Maintains sharpness under high-speed grinding, improving productivity.

Technical Specifications

| Item | Details |

|---|---|

| Code No. | CBN-A10 |

| Color | Amber |

| Particle Shape | Irregular |

| Toughness | Medium |

| Available Mesh Sizes | 50/60–325/400 mesh |

| Bond Compatibility | Resin bond |

| Target Materials | Ferrous metals, alloy steel |

FAQ

Q1: What mesh sizes are available for CBN-A10?

A: CBN-A10 is available in 50/60 (rough grinding), 120/140 (medium grinding), and 325/400 mesh (fine grinding) to meet various resin bond tool requirements.

Q2: Can CBN-A10 be used for non-ferrous metals?

A: It is optimized for ferrous metals (carbon steel, alloy steel). For non-ferrous metals like aluminum or copper, we recommend SinoDiam’s diamond micron series (e.g., SND-M10).

Q3: Why is self-sharpening important?

A: Self-sharpening prevents resin-bonded tools from glazing and losing efficiency, ensuring longer tool life and consistent grinding results, especially in steel part finishing applications.

CBN-A20 Amber Regular CBN for Vitrified, Metal, and Electroplated Multi-Bond Tool Applications

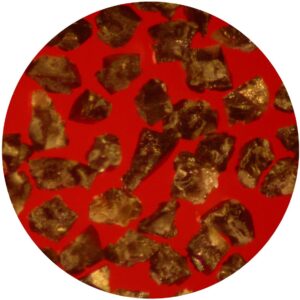

CBN-B10 Black Friable CBN (50/60–325/400 Mesh) – Resin Bond CBN for Fine Ferrous Metal Grinding

Reviews

There are no reviews yet.