Titanium Carbide-Coated Diamond (TiC-Coated Diamond)

SinoDiam TiC-Coated Diamond – Inert Coating for Clean & Tough Workpieces

Top Introduction

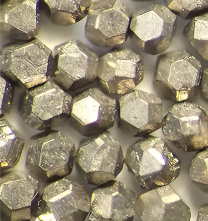

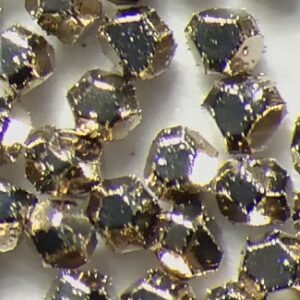

SinoDiam Titanium Carbide-Coated Diamond is a high-performance, surface-functionalized diamond with an inert, brittle titanium carbide (TiC) coating.

The coating prevents chemical reactions with workpieces, boosts matrix adhesion, and reduces surface damage—making it ideal for metal and ceramic bond tools processing tough or precision surfaces.

Description

SinoDiam TiC-Coated Diamond features a complete and uniform titanium carbide coating that provides two key advantages:

- Inertness: Resists chemical reactions with workpieces like high-alloy steel, preventing contamination.

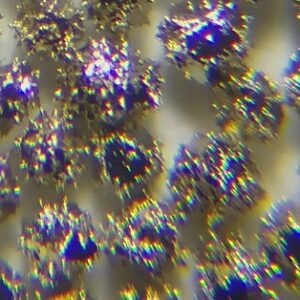

- Controlled Brittleness: Reduces scratches or marks on processed surfaces, ideal for precision parts and glass grinding.

The TiC layer also enhances matrix adhesion by 35% compared with uncoated diamond.

Available in 325/400 mesh and coarser, it fits heavy-duty grinding wheels, hot-press tools, and ceramic bond applications, ensuring clean and efficient processing on tough materials.

Core Advantages

- 🛡 Inert & Clean Processing: Titanium carbide coating prevents chemical reactions and debris, maintaining clean surfaces for precision workpieces.

- 🌡 Thermal/Chemical Protection: Resists heat damage up to 850°C and prevents matrix-diamond reactions, extending tool lifespan by 30%.

- 💪 Tough Workpiece Suitability: Handles high-alloy steel, hard metals, and precision surfaces without coating wear or contamination.

- 🧼 Controlled Brittleness: Reduces scratching on delicate or clean-surface applications, such as glass or precision ceramics.

Technical Specifications

| Item | Details |

|---|---|

| Product Name | Titanium Carbide-Coated Diamond |

| Available Grades | 325/400 mesh & coarser (all grades) |

| Coating Feature | Inert, brittle TiC; complete, uniform; strong bonding |

| Bond Compatibility | Metal bond, ceramic bond |

| Target Workpieces | Tough metals (high-alloy steel), precision or clean surfaces |

| Temperature Resistance | ≤850°C |

FAQ

Q1: Why is this diamond ideal for clean-surface processing?

A: The inert TiC coating does not react with workpieces or shed debris, ensuring a clean surface without extra cleaning steps.

Q2: Can it be used for ceramic bond tools processing glass?

A: Yes. Its controlled brittleness prevents scratches, and the inert coating avoids residue, perfect for glass grinding wheels.

Q3: How does TiC coating compare to Titanium coating?

A: TiC is more inert and heat-resistant (≤850°C vs. 800°C), ideal for clean surfaces or tough workpieces, while Titanium is more flexible and better for general bonding.

Отзывы

Отзывов пока нет.