SND-MAG Diamond Agglomerated Micron Powder – Polycrystalline-Like Abrasive for Scratch-Free Grinding & Polishing of Semiconductors, Sapphire & Hard Materials

SND-MAG is a next-generation diamond agglomerated micron powder, engineered for scratch-free high-precision grinding and polishing of semiconductors (Si, SiC, GaAs, GaN, InP), sapphire substrates, advanced ceramics, and precision metals.

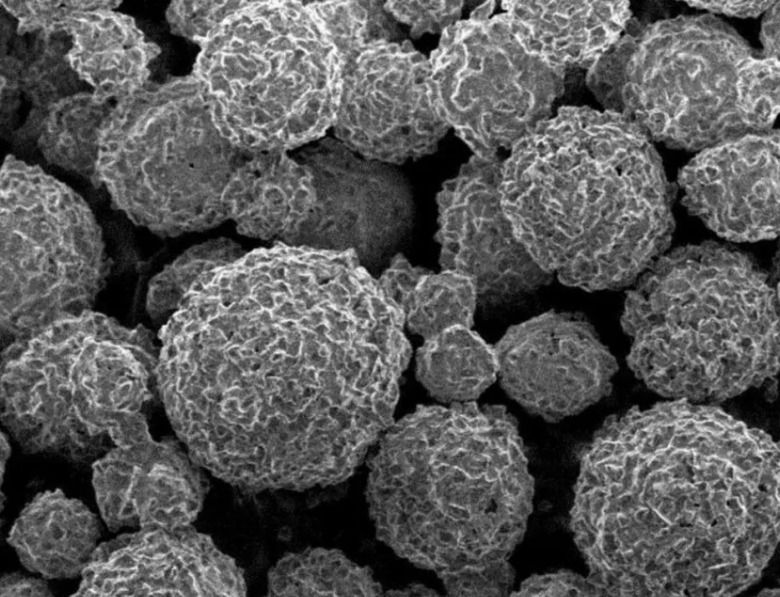

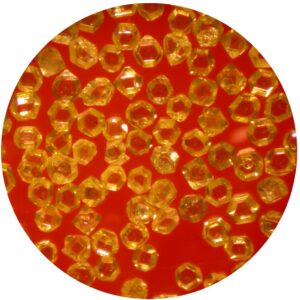

Developed by SinoDiam International, SND-MAG integrates ultra-pure diamond micro-powder with a specialized high-strength binder, forming a stable polycrystalline-like agglomerated structure via a proprietary low-temperature sintering and binder curing process (800–850°C). This innovative design mimics polycrystalline diamond performance, providing high material removal rates, uniform surface finish, and extended tool life while remaining cost-effective compared to traditional polycrystalline diamond powders.

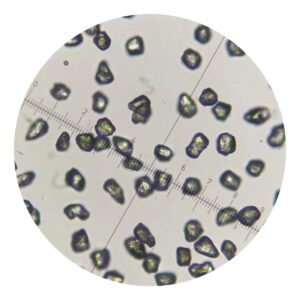

The class-spherical shape (verified by TEM) with rough, micro-structured particle surfaces ensures:

- Uniform contact with wafers and hard substrates

- Excellent suspension in aqueous or oil-based grinding fluids

- Controlled, scratch-free material removal (Ra ≤0.05μm)

- “Self-renewing” grinding layer for stable efficiency over 10+ hours

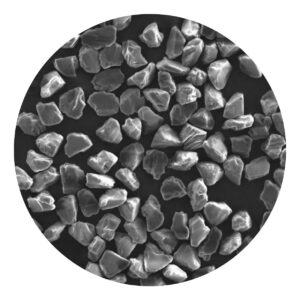

SND-MAG outperforms conventional single-crystal diamond powders, offering higher grinding efficiency, superior adhesion to resin or vitrified bonds, and zero deep scratches, making it the ideal choice for semiconductor wafer lapping, sapphire polishing, optical lens finishing, and high-precision ceramic grinding.

Technical Edge & Engineering

- Agglomeration Craftsmanship: Proprietary sintering + binder curing forms polycrystalline-like agglomerates, preventing diamond graphitization and maintaining structural integrity under high-pressure grinding (≤50 N/cm²).

- Shape & Uniformity Control: 90%+ class-spherical particles (TEM-verified), shape deviation ≤10%, ensuring stable polishing force, reduced vibration, and minimized surface defects.

- Ultra-Low Impurity Levels: Triple purification (acid leaching, vacuum degassing, magnetic separation) ensures compatibility with high-purity semiconductor materials, preventing contamination during wafer polishing.

Key Advantages

- High-Efficiency Polishing: Self-renewing agglomerated structure maintains consistent grinding/polishing efficiency for 10+ hours, extending tool life by 50% compared to conventional diamond powders.

- Scratch-Free Surface Finish: Class-spherical shape and micro-cutting edges deliver Ra ≤0.05μm on sapphire, SiC, and semiconductor wafers, with scratch rates <0.3%.

- Multi-Material Adaptability: Suitable for Si, SiC, GaAs, GaN, InP wafers, sapphire, advanced ceramics, and precision metals—reducing the need to switch abrasives on multi-material production lines.

- Enhanced Bonding & Adhesion: Rough micro-particle surfaces improve bond retention in resin or vitrified polishing pads, minimizing grit shedding and extending pad life.

Core Applications Across Industries

Semiconductor & Electronics:

- Wafer Polishing & Lapping: Polishes silicon, SiC, GaAs, GaN, InP wafers with Ra ≤0.05μm, ensuring high yield and defect-free surfaces.

- Wafer Edge Trimming: Removes micro-cracks from 6–12-inch wafers, improving subsequent chip packaging reliability.

Optics & Hard Materials:

- Sapphire Substrate Polishing: Achieves scratch-free surfaces and ≥95% light transmittance for LEDs, smartphone lenses, and high-end optical components.

- Ceramic & Metal Finishing: Polishes alumina ceramics, titanium alloys, and other precision components to mirror-like surfaces without post-processing buffing.

Technical Specs

| Technical Item | Status / Value | Remarks |

|---|---|---|

| Product Code | SND-MAG | Official identifier |

| Appearance | Gray powder | Visual inspection |

| Shape | Class-spherical | TEM verified |

| Crystal Form | Polycrystalline | X-ray diffraction confirmed |

| Density | 3.1–3.4 g/cm³ | Pycnometer measurement |

| Composition | C>99%, Mg<0.1%, B<0.005%, Others<0.1% | ICP-MS |

| Combustion Ash | <0.1% | High-temperature test |

| Particle Size Range | 1–5μm, 5–10μm, 10–20μm | Customizable per application |

| Suspensibility | ≥95% (24h) | Turbidity measurement |

| Thermal Stability | Up to 850°C | TGA |

| Grinding Pressure Resistance | ≤50 N/cm² | Compression test |

FAQ

Q1: Why is the class-spherical shape critical for SND-MAG?

A: Class-spherical particles ensure uniform contact with substrates, avoid localized high-pressure scratches, and maintain consistent polishing across large wafers (e.g., 12-inch SiC or Si wafers).

Q2: Can SND-MAG be used for GaN semiconductor wafers?

A: Yes. Ultra-low impurities (B <0.005%, Fe <0.1%) prevent contamination, achieving Ra ≤0.05μm surfaces, meeting high-frequency chip fabrication standards.

Q3: How does the “self-renewing grinding layer” function?

A: Agglomerates gradually expose fresh diamond surfaces during use, maintaining constant grinding efficiency for 10+ hours and reducing tool replacement downtime by 30%.

Q4: What is the recommended storage method for SND-MAG?

A: Store in vacuum-sealed, moisture-proof aluminum foil bags at 15–25°C, <60% RH. Avoid dust and corrosive gases. Shelf life: 36 months.

SND-MPL Polycrystalline Synthetic Micron Diamond Powder

Reviews

There are no reviews yet.