Titanium-Coated Diamond (SinoDiam Titanium-Plated Series)

Top Introduction

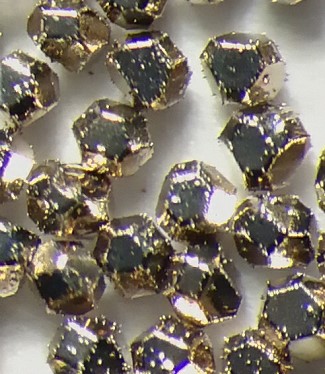

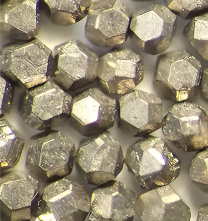

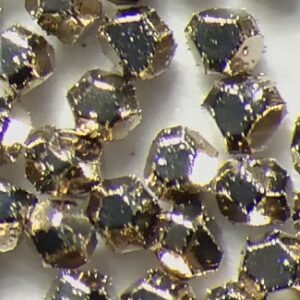

SinoDiam Titanium-Coated Diamond—also known as Titanium-Plated Diamond—is a premium surface-treated diamond engineered with a complete, uniform titanium coating that bonds tightly to each crystal. This advanced coating acts as a thermal and chemical shield, protecting the diamond during hot-press sintering, brazing, or high-load grinding. It greatly enhances the adhesion between the diamond and tool matrix, making it ideal for metal bond and ceramic bond tools, including hot-press wheels, brazed tools, and welding tools.

Description

SinoDiam Titanium-Coated Diamond features a uniform, seamless titanium layer designed to create a strong chemical bond between the coating and the diamond surface.

This coating forms a protective barrier that prevents oxidation, graphitization, and reactions between diamond and metal alloy matrices during high-temperature tool manufacturing (up to 800°C) or operation.

As a result, tool life is extended by 30% compared with uncoated diamond, while maintaining superior cutting, grinding, and wear performance.

Available in 325/400 mesh and coarser sizes, it’s perfectly suited for large-particle metal bond and ceramic bond tools—such as heavy-duty grinding discs, saw blades, and brazed tools.

Core Advantages

- 🛡 Thermal & Chemical Protection – Titanium coating resists heat up to 800°C and prevents diamond–matrix reactions, reducing tool wear and failure by up to 25%.

- ⚙ Superior Matrix Adhesion – Strong bonding between coating and diamond ensures excellent retention in metal bond and ceramic bond matrices, ideal for hot-press and brazed tools.

- 🔩 Enhanced Tool Life – Extends tool lifespan and maintains consistent performance under high mechanical and thermal loads.

- 🌍 Wide Compatibility – Perfect for metal bond, ceramic bond, and brazing/welding applications in cutting, grinding, and drilling tools.

Technical Specifications

| Item | Details |

|---|---|

| Product Name | Titanium-Coated Diamond |

| Available Grades | 325/400 mesh & coarser (e.g., 230/270, 120/140 mesh) |

| Coating Type | Complete, uniform titanium plating |

| Coating Function | Thermal and chemical protection; enhances matrix adhesion |

| Bond Compatibility | Metal bond, ceramic bond |

| Target Tools | Hot-press tools, brazed/welding tools, grinding discs |

| Working Temperature | ≤800°C |

FAQ

Q1: What mesh sizes are available for Titanium-Coated Diamond?

A: Available in 325/400 mesh and coarser grades (such as 230/270, 120/140 mesh) for heavy-duty grinding and cutting tools.

Q2: Can it be used for resin bond tools?

A: It’s optimized for metal and ceramic bond tools. For resin bond applications, use SinoDiam Nickel-Plated Diamond (N56 Series)—specially formulated for resin matrices.

Q3: How does the titanium coating extend tool life?

A: The coating prevents oxidation, graphitization, and detachment during hot-pressing or brazing, extending tool life by up to 30% compared to uncoated diamond.

Beoordelingen

Er zijn nog geen beoordelingen.