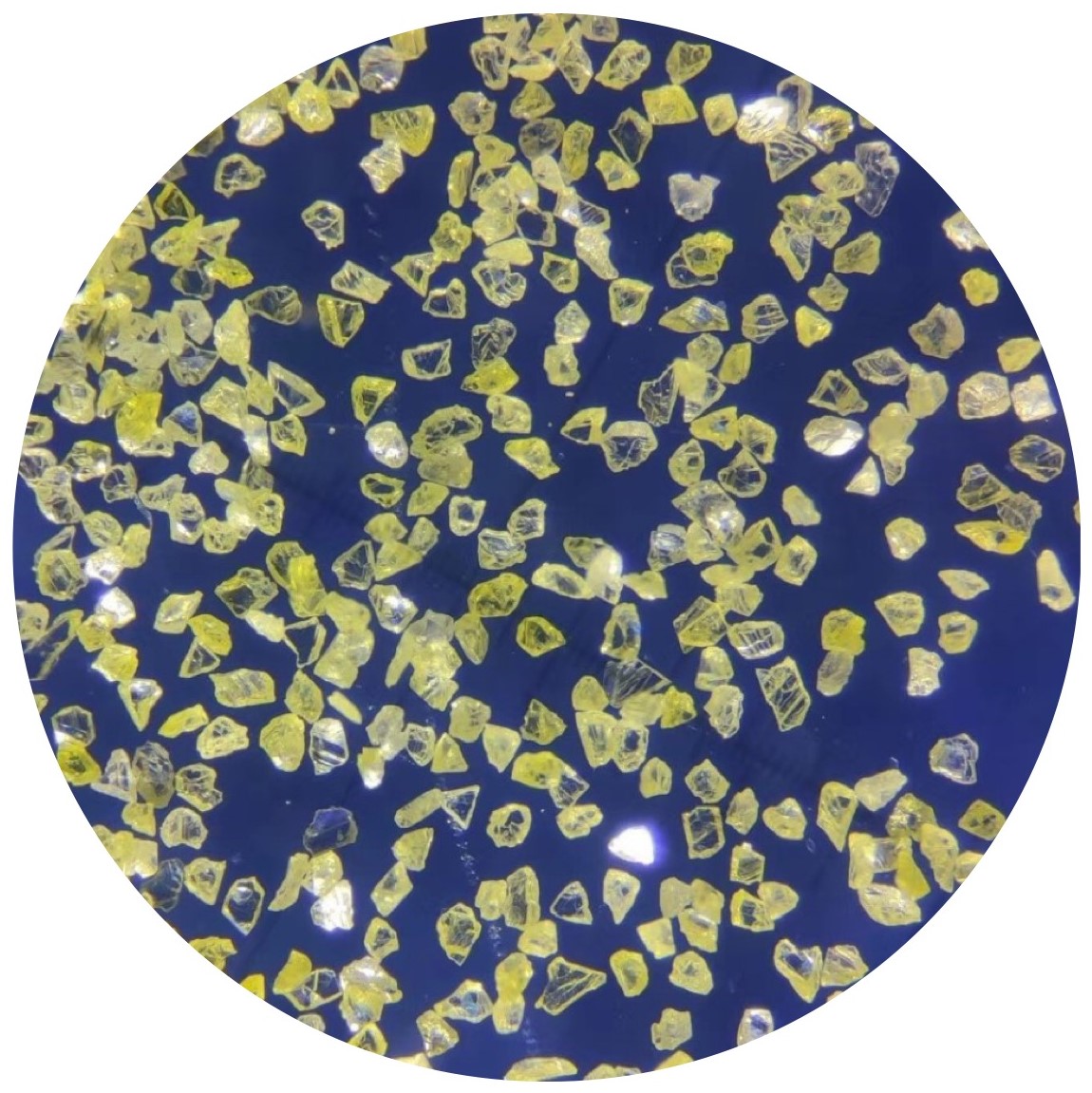

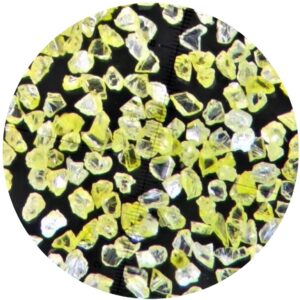

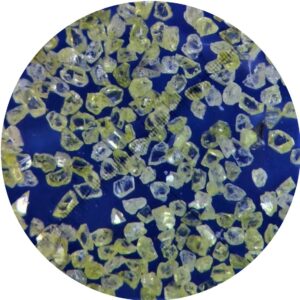

SND-G10 Crushed Yellow RVD Diamond: ZND2110-Grade for Precision Stone Polishing & Resin Bond Tools

Description:

Crafted from ZND2110-grade natural diamond with an impurity content ≤0.02%, SND-G10 offers exceptional purity for a scratch-free surface finish. Its 2-step quality control process (crystal purity testing → particle size calibration) ensures consistent granule shape and size (±4% tolerance), providing reliable performance batch after batch.

Key Advantages of SND-G10:

- Superior Surface Finish: Creates a mirror-like gloss (≥90°) on marble and granite, reducing the need for secondary buffing, and cutting project time by 25%. Ideal for luxury stone polishing applications like hotel lobbies and high-end residential floors.

- Strong Resin Bond Compatibility: 1.8x better adhesion to resin bases than generic RVD diamonds, significantly extending the lifespan of resin bond polishing pads and improving tool efficiency.

- Cost Savings: Reduces polished stone reject rates by 15% and lowers annual tool replacement costs by 20%, making it a cost-effective choice for stone processing factories.

Core Applications (NA/EU Focused):

- Marble & Granite Polishing: Used in luxury hotel lobbies (EU: Italian marble) and high-end residential granite countertops (NA), achieving a scratch-free gloss ≥90° for premium stone finishes.

- Tungsten Steel Mold Trimming: Trims plastic part molds with micron-level precision (NA: consumer goods manufacturers), ensuring cavity accuracy within 0.005mm, vital for high-precision mold making.

- Natural Diamond Pre-Shaping: Shapes rough jewelry-grade diamonds (EU: Belgian diamond workshops) without internal fractures, streamlining pre-processing for luxury jewelry.

Available Mesh Sizes:

Standard 100/120, 200/230, 325/400 mesh (optimized for polishing); custom sizes available upon request (MOQ: 25kg/55lbs).

FAQ:

Q1: What stones is SND-G10 best for polishing?

A: SND-G10 excels at medium-hardness stones such as marble, granite, and onyx. Its sharp edges prevent over-polishing of softer stones (e.g., limestone) while delivering high gloss on harder stones like black granite (NA). Perfect for luxury stone polishing projects.

Q2: Can SND-G10 be used in ceramic bond tools?

A: Yes! SND-G10 is fully compatible with ceramic bond systems. It is used by EU mosaic tile manufacturers in ceramic bond wheels to efficiently cut 500+ small tiles (10x10mm) per tool, maintaining sharpness and accuracy without compromise.

Q3: How does SND-G10 compare to standard RVD diamonds for resin bond tools?

A: SND-G10 offers 30% sharper edges and 20% better crystal integrity than standard RVD diamonds, which translates to less pressure required during use, reducing tool wear by 40%. This results in improved surface quality—a crucial factor for high-end stone polishing and resin bond applications.

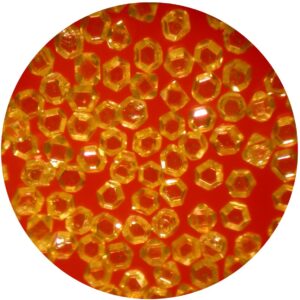

SND-G05 Economy Crushed Green RVD | 80-500 Mesh for Stone/Ceramic/Glass Processing Tools

Beoordelingen

Er zijn nog geen beoordelingen.