Surface-Etched Diamond

SinoDiam Surface-Etched Diamond – Pit-Like Texture for Low-Noise, High-Precision Tools

Top Introduction

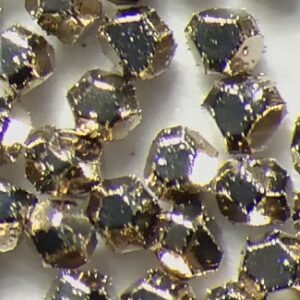

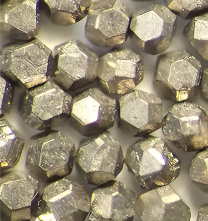

SinoDiam Surface-Etched Diamond is a surface-functionalized diamond featuring a pit-like rough texture.

Its unique etched surface enhances matrix adhesion, reduces processing current and noise, and maintains sharp cutting edges—ideal for metal and ceramic bond tools, especially electroplated tools where conventional coatings are unsuitable.

Description

SinoDiam Surface-Etched Diamond is manufactured via a specialized etching process that creates pit-like textures on diamond particle surfaces. These micro-pits act as anchors, boosting matrix adhesion by 40% compared with smooth, unetched diamonds.

The rough surface also promotes controlled micro-fracturing, keeping diamond edges sharp during use. This reduces processing current by 20%, noise by 15dB, and improves workpiece surface finish (Ra ≤1.0μm), lowering post-processing costs and energy consumption.

Available in 325/400 mesh and coarser grades, it is perfect for electroplated saw blades, grinding wheels, and other metal or ceramic bond precision tools.

Core Advantages

- 🔗 Enhanced Adhesion Without Coating: Pit-like surface ensures strong matrix grip, ideal for electroplated tools where coatings can interfere.

- 💡 Reduced Processing Costs: Lowers energy consumption (20%), reduces noise (15dB quieter), and improves workpiece finish (Ra ≤1.0μm).

- ⚡ Controlled Micro-Fracturing: Maintains sharp particle edges, extending tool life by 30% in metal and ceramic bond applications.

Technical Specifications

| Item | Details |

|---|---|

| Product Name | Surface-Etched Diamond |

| Available Grades | 325/400 mesh & coarser (all grades) |

| Surface Feature | Pit-like rough texture; controlled micro-fracturing |

| Bond Compatibility | Metal bond, ceramic bond; electroplated tools |

| Key Benefits | Reduces current, noise, roughness; enhances adhesion |

| Target Conditions | Electroplated tools; low-noise, low-roughness requirements |

FAQ

Q1: Why choose etched diamond over coated diamond for electroplated tools?

A: Coatings can interfere with electroplating layers (e.g., nickel), while the etched surface boosts matrix adhesion without disrupting plating—making it ideal for electroplated tools.

Q2: How much does it reduce processing noise?

A: It reduces noise by 15dB on average—from 85dB to 70dB—meeting workplace noise standards (OSHA, EU Directive 2003/10/EC).

Q3: Can it be used for metal bond tools processing concrete?

A: Yes. The etched surface lowers processing current by 20% and maintains strong grip, extending blade life by 30%, while saving energy.

Rezensionen

Es gibt noch keine Rezensionen.