What Is Diamond Compound Paste?

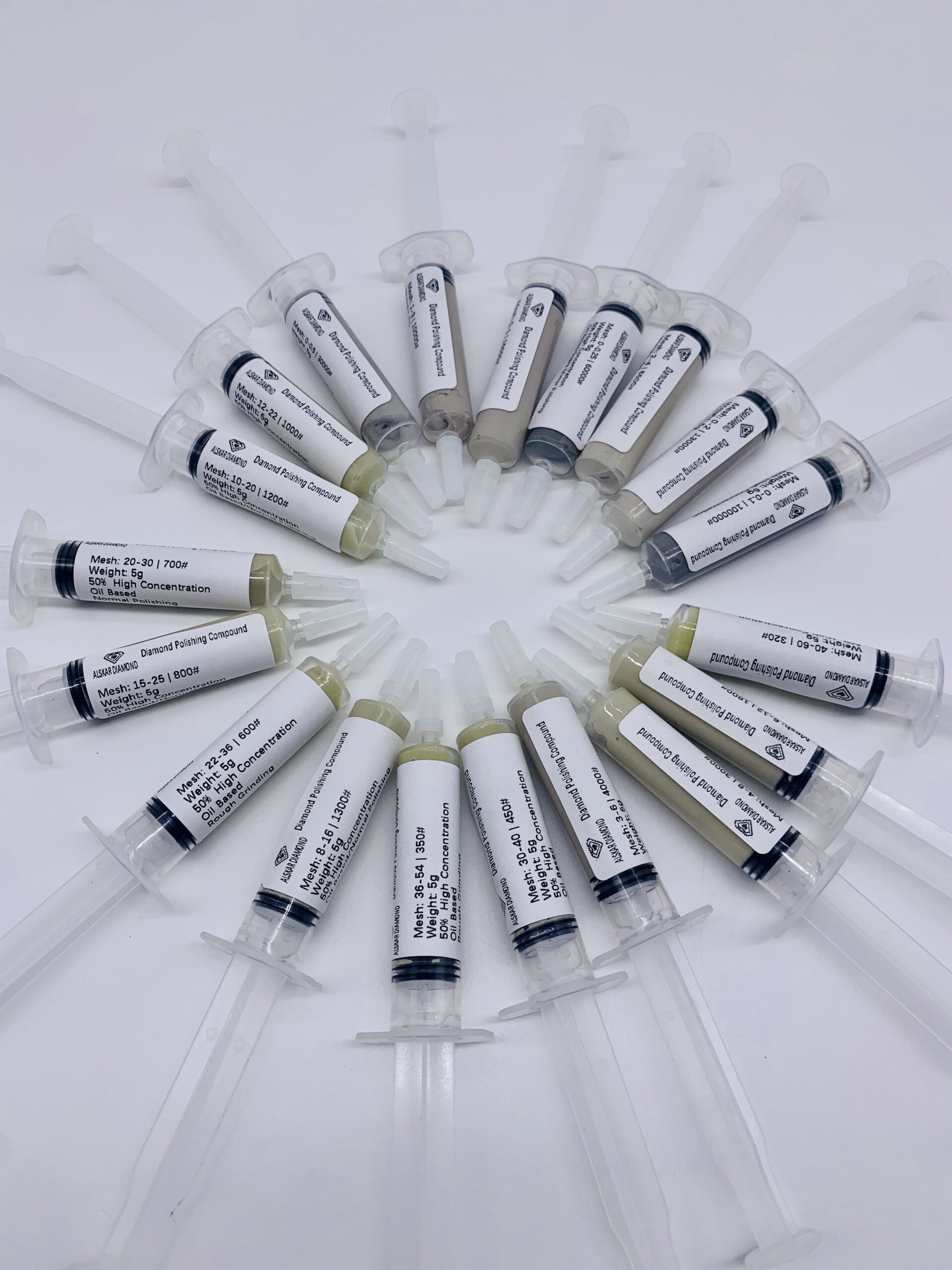

Diamond Compound Paste is a high-performance superabrasive solution composed of synthetic diamond particles suspended in a carrier (oil, water, or wax). It is designed for precision polishing, lapping, and grinding of hard materials such as metals, carbide, ceramics, and glass.

Key Advantages of Diamond Compound Paste

- Exceptional Hardness: Diamond is the hardest known material (Vickers hardness ~100 GPa), enabling efficient cutting and polishing of hard metals and ceramics.

- Controlled Particle Distribution: Micron- and submicron-sized diamond particles ensure consistent surface finish and material removal.

- Versatile Carrier Options: Available in oil-soluble, water-soluble, and wax-based compounds for different polishing processes.

- Reduced Workpiece Damage: Low friction and uniform particle size minimize surface scratches, burrs, and deformation.

Diamond compound paste is widely used in precision grinding, mold polishing, die finishing, optical lens fabrication, and semiconductor component processing.

Core Applications of Diamond Compound Paste

1. Precision Polishing & Lapping

- Mold & Die Polishing: Achieve mirror-like finishes on cold heading dies, forging dies, and carbide molds.

- Semiconductor & Electronics: Polishes stainless steel, silicon wafers, and other hard components for high-precision, dust-free surfaces.

- Optical Components: Used in lens polishing and glass finishing, providing smooth, scratch-free surfaces.

2. Industrial Grinding & Surface Finishing

- Carbide & Hard Metal Finishing: Ensures high-precision tolerances on cutting tools, dies, and bearings.

- Metal & Alloy Polishing: Suitable for stainless steel, tungsten carbide, and other hard alloys.

- Ceramic & Stone Processing: Polishes advanced ceramics, engineered stones, and granite for industrial and decorative applications.

SinoDiam Diamond Compound Paste Product Series

SinoDiam provides a comprehensive range of diamond compound pastes, designed for precision grinding, polishing, and lapping across multiple industries. Each grade is engineered for particle size, carrier type, and application-specific performance.

1. SND210 Oil-Soluble Diamond Compound

Core Identity: Premium oil-soluble diamond paste for high-precision mold, die, and carbide polishing.

- Particle Size Range: 0.5 μm – 30 μm

- Carrier: Oil-soluble

- Performance Advantages:

- Smooth and consistent material removal

- High adhesion for resin and metal surfaces

- Ideal for fine lapping and finishing

- Ideal Applications: Carbide dies, mold polishing, precision tool finishing

Learn More

2. SND220 Water-Soluble Diamond Compound

Core Identity: Advanced water-soluble paste for metal, ceramic, and stone polishing.

- Particle Size Range: 0.5 μm – 25 μm

- Carrier: Water-soluble

- Performance Advantages:

- Environmentally friendly and easy to clean

- Reduces heat buildup during high-speed polishing

- Provides ultra-smooth surfaces with minimal scratching

- Ideal Applications: Stainless steel components, precision ceramics, semiconductor parts

Learn More

3. SND230 Wax-Based Diamond Compound

Core Identity: Wax-based diamond paste for high-precision optical and glass polishing.

- Particle Size Range: 0.25 μm – 10 μm

- Carrier: Wax-based

- Performance Advantages:

- Superior adhesion for intricate surfaces

- Maintains consistent diamond suspension

- Ideal for polishing glass, optical lenses, and mirrors

- Ideal Applications: Optical lenses, glass panels, precision mirrors

Learn More

Quick Selection Guide: Diamond Compound Paste

| Product | Carrier Type | Particle Size (μm) | Core Strengths | Ideal Applications |

|---|---|---|---|---|

| SND210 | Oil-Soluble | 0.5 – 30 | High adhesion, smooth lapping | Carbide dies, mold polishing, precision tools |

| SND220 | Water-Soluble | 0.5 – 25 | Eco-friendly, low heat, smooth finish | Stainless steel, ceramics, semiconductor parts |

| SND230 | Wax-Based | 0.25 – 10 | Superior adhesion, optical polishing | Lenses, mirrors, glass panels |

Why Choose SinoDiam Diamond Compound Paste?

- High Purity Synthetic Diamond: ≥99.8% purity for consistent cutting and polishing.

- Precise Particle Control: Tight particle size distribution ensures uniform material removal.

- Tailored Formulations: Oil, water, and wax carriers for different polishing applications.

- Technical Support: Free consultation to select the optimal paste for your process.

Enhance precision, efficiency, and surface quality with SinoDiam Diamond Compound Paste.

FAQ: SinoDiam Diamond Compound Paste

1. What is diamond compound paste used for?

Diamond compound paste is used for precision grinding, lapping, and polishing of hard metals, carbide, ceramics, glass, and optical components.

2. What types of carriers are available for diamond paste?

- Oil-soluble: Ideal for fine polishing of molds and carbide tools

- Water-soluble: Eco-friendly, reduces heat, suitable for metals and ceramics

- Wax-based: Adhesive carrier for optical glass and lenses

3. What particle sizes are commonly available?

SinoDiam diamond compounds range from 0.25 μm to 30 μm, allowing precise material removal and mirror-like finishes.

4. Can diamond paste be used on carbide tools?

Yes, it is ideal for polishing and lapping carbide dies and cutting tools, ensuring high precision and smooth surfaces.

5. Is water-soluble diamond paste environmentally friendly?

Yes, it reduces chemical residues and is easier to clean compared to oil-based compounds.

6. How do I choose the right diamond paste?

Consider material type, desired surface finish, carrier type, and particle size. Our technical team can recommend the optimal product.

7. Can diamond paste be used for polishing optical lenses?

Yes, wax-based diamond compounds are optimized for glass and optical lens polishing, providing scratch-free, high-precision surfaces.

8. What are the advantages over traditional abrasives?

Diamond paste offers higher hardness, precision particle control, and low friction, enabling faster polishing and superior surface quality.

9. Can it be used in high-speed polishing machines?

Yes, diamond paste is compatible with manual and machine polishing, including high-speed applications, without burning or scratching the surface.

10. Why choose SinoDiam Diamond Compound Paste?

We provide high-purity synthetic diamonds, precise particle distribution, multiple carriers, and expert technical support to ensure maximum efficiency, precision, and tool life.

Reviews

There are no reviews yet.