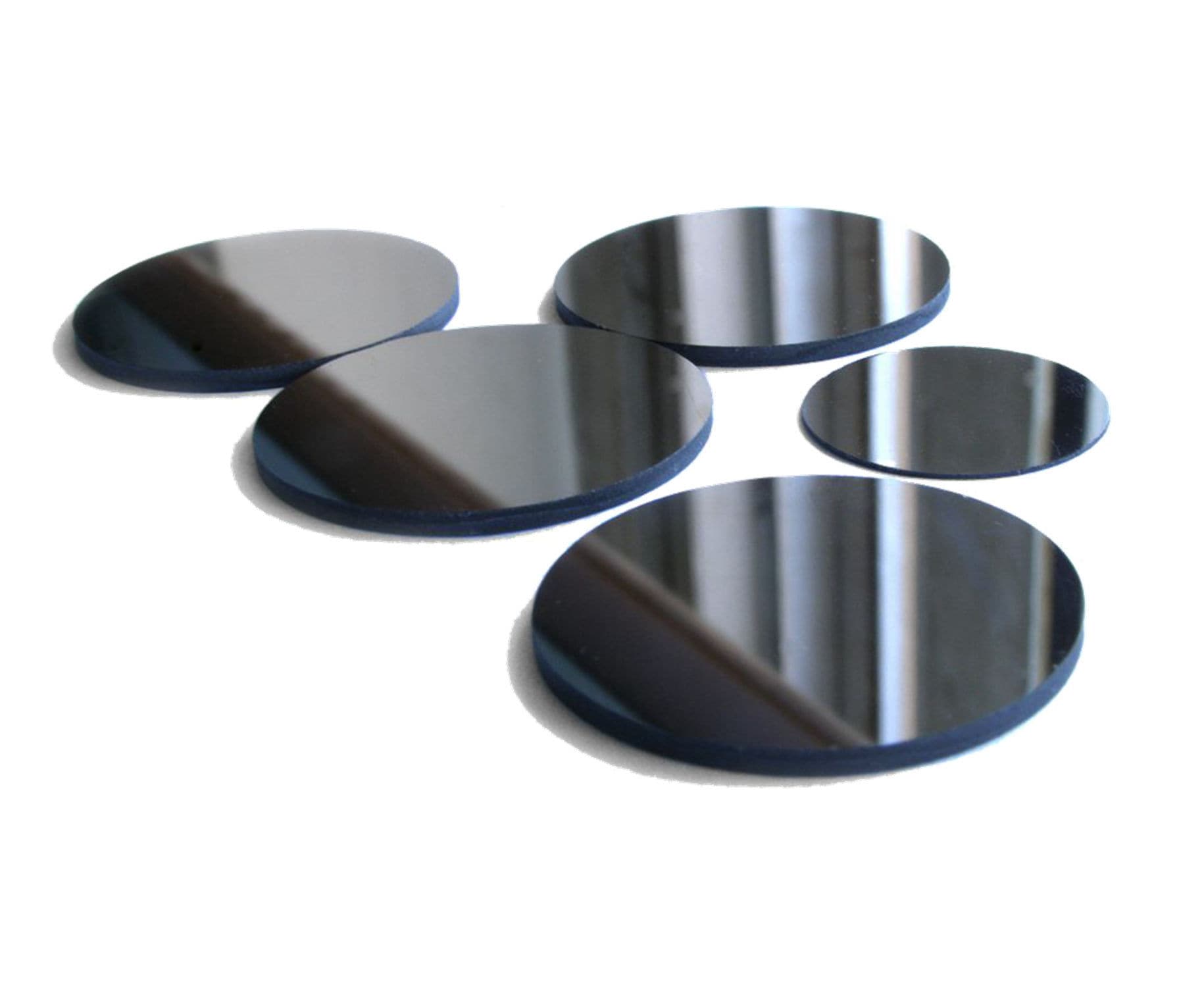

1. What Are Polycrystalline Diamond (PCD) Tools?

Polycrystalline Diamond (PCD) Tools are engineered from sintered synthetic diamond particles under High Pressure High Temperature (HPHT) conditions. They offer exceptional hardness, wear resistance, and thermal stability, making them ideal for precision machining of non-ferrous metals, composites, and abrasive materials.

Key Advantages:

- Extreme Hardness: Efficient cutting of aluminum alloys, copper, and composite materials.

- Long Tool Life: PCD tools resist wear and maintain precision over extended operations.

- High Thermal Stability: Withstands high-speed cutting without losing structural integrity.

- Consistent Precision: Polycrystalline structure ensures uniform cutting edges and reduced vibration.

Applications:

- Precision machining of aluminum, copper, and non-ferrous alloys

- Cutting and milling of composites, graphite, and abrasive materials

- Industrial tooling for turning, milling, and shaping high-performance materials

2. What Are PCBN Composites?

Polycrystalline Cubic Boron Nitride (PCBN) Composites combine CBN crystals with a metallic or ceramic binder, creating ultra-hard cutting tools for ferrous materials. PCBN is optimized for precision machining of hardened steels, cast irons, and high-performance alloys, where conventional tools cannot perform efficiently.

Key Advantages:

- Exceptional Hardness & Wear Resistance: Ideal for hardened steel (HRC 50+) and cast iron

- High Thermal Stability: Maintains cutting edge at high temperatures

- Chemical Inertness: Does not react with iron or steel, avoiding tool degradation

- High Precision: Ensures tight tolerances and excellent surface finishes

Applications:

- Precision turning and milling of hardened steels and superalloys

- Cutting inserts for automotive, aerospace, and industrial tooling

- Heavy-duty machining of cast iron components

Learn More About PCBN Composites

3. Quick Selection Guide: PCD & PCBN Tools

| Product Type | Core Material | Target Material | Core Strengths | Ideal Applications |

|---|---|---|---|---|

| PCD Tools | Polycrystalline Diamond | Non-ferrous metals, composites, graphite | Extreme hardness, long tool life, high precision | Aluminum alloys, copper, composites, industrial milling |

| PCBN Composites | Polycrystalline CBN + Binder | Hardened steels, cast iron, high-performance alloys | Exceptional wear resistance, thermal stability, chemical inertness | Automotive gears, bearings, tool steel, cast iron components |

4. Why Choose SinoDiam PCD & PCBN Tools?

- HPHT Technology: High-purity synthetic diamonds and CBN for maximum hardness and durability

- Tailored Solutions: Customizable specifications for cutting geometry, crystal size, and binder composition

- Consistent Performance: Tools maintain precision and wear resistance under extreme conditions

- Technical Support: Expert guidance for selecting the right tool for your machinery and materials

5. FAQs: PCD & PCBN Tools

1. What are the differences between PCD and PCBN?

- PCD: Best for non-ferrous metals, composites, and abrasive materials

- PCBN: Best for ferrous metals, hardened steels, and cast iron

2. Can PCD tools be used for composites?

Yes, PCD is ideal for composite machining, aluminum, and non-ferrous alloys.

3. Are PCBN tools suitable for hardened steel?

Yes, PCBN tools excel in precision machining of hardened steel (HRC 50+) and cast iron.

4. Can these tools be customized?

Yes, we provide custom crystal size, geometry, and binder composition based on your application needs.

5. How long do PCD and PCBN tools last?

Both offer 2–5x longer service life than conventional carbide tools, depending on material and application.

6. What industries use PCD and PCBN tools?

Automotive, aerospace, electronics, construction, and metalworking industries rely on these tools for precision machining and long-life performance.

7. What materials should I choose PCD vs PCBN for?

- PCD: Aluminum, copper, composites, graphite

- PCBN: Hardened steel, cast iron, high-performance alloys

8. Are these tools high-speed compatible?

Yes, both PCD and PCBN maintain cutting performance and thermal stability at high speeds.

9. How does SinoDiam ensure quality?

All tools undergo strict HPHT synthesis, quality testing, and performance verification before delivery.

10. Why choose SinoDiam?

We offer high-purity PCD and PCBN tools, customizable solutions, technical support, and consistent high performance for industrial precision machining.

Değerlendirmeler

Henüz değerlendirme yapılmadı.