Nickel-Plated Diamond (N30 Grade)

SinoDiam N30 Multi-Bond Nickel-Coated Diamond – For High-Temperature Tool Conditions

Top Introduction

SinoDiam Nickel-Plated Diamond N30 is a multi-bond, high-temperature resistant diamond coating designed for versatility and durability.

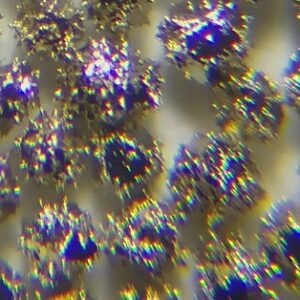

Featuring a uniform nickel coating that bonds strongly to each diamond crystal, N30 effectively protects against thermal oxidation, graphitization, and chemical damage—while significantly improving matrix adhesion.

Compatible with metal, ceramic, and resin bonds, N30 eliminates the need for separate coated diamond grades, making it ideal for hot-press, brazed, and resin-bonded tools used in heavy-duty grinding, polishing, and cutting.

Description

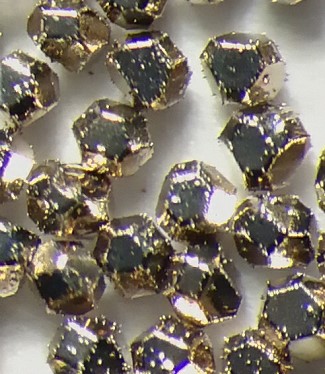

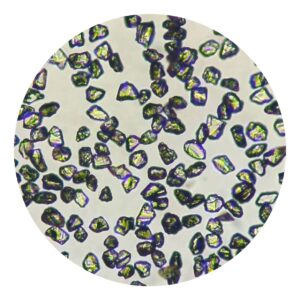

SinoDiam Nickel-Plated Diamond N30 features a complete and uniform nickel coating applied through precision electroplating.

The coating forms a tightly bonded metallic layer that ensures superior diamond retention in various bond systems—especially under high mechanical and thermal stress.

With heat resistance up to 900°C (tool forming) and 750°C (operating use), N30 maintains crystal integrity and matrix bonding, even in demanding production environments like heavy-load metal grinding and hot-press sintering.

Compared with uncoated diamond, N30 increases matrix adhesion by 40%, reduces diamond pull-out, and extends tool lifespan by over 30%, ensuring consistent cutting and polishing performance across all bond types.

Core Advantages

- 🔥 Multi-Bond Versatility: Works seamlessly with metal, ceramic, and resin bonds, perfect for workshops handling mixed production.

- 🌡 High-Temperature Resistance: Stable up to 900°C (forming) and 750°C (use)—ideal for hot-press and heavy-duty tools.

- ⚙ Strong Matrix Adhesion: Nickel coating strengthens surface bonding, reducing diamond loss by 35% during extended operation.

- 💎 Uniform Coating Quality: Precision electroplated layer ensures even coverage for reliable performance and smooth tool operation.

Technical Specifications

| Item | Details |

|---|---|

| Product Name | Nickel-Plated Diamond N30 |

| Available Grades | 500/600 mesh & coarser (all grades) |

| Coating Type | Complete, uniform nickel coating |

| Coating Function | Thermal and chemical protection; enhanced surface bonding |

| Bond Compatibility | Metal, ceramic, resin |

| Temperature Resistance | Forming ≤900°C, Use ≤750°C |

| Target Conditions | High-temperature tool forming and operation |

FAQ

Q1: Why is N30 suitable for high-temperature tool conditions?

A: Its nickel coating remains stable at 900°C forming temperature and 750°C operating temperature, preventing oxidation, delamination, or diamond degradation during heavy-duty processing.

Q2: Can N30 be used for resin bond polishing pads?

A: Yes. Its triple-bond compatibility makes it ideal for resin-bond polishing pads, especially those operating in high-heat environments such as automotive parts and precision polishing.

Q3: What’s the difference between N30 and N56 Nickel-Plated Diamond?

A: N30 is designed for multi-bond and high-temperature resistance, while N56 features a spiny surface that improves grip for resin and ceramic bonds. Choose N30 for versatile, high-heat conditions; choose N56 for resin-specific applications.

Değerlendirmeler

Henüz değerlendirme yapılmadı.