SND-MDW Professional Synthetic Micron Diamond Powder For Silicon Wafer Cutting Diamond Wire

SND-MDW Professional Synthetic Micron Diamond Powder For Silicon Wafer Cutting Diamond Wire

1. Micron Diamond Powder Introduction

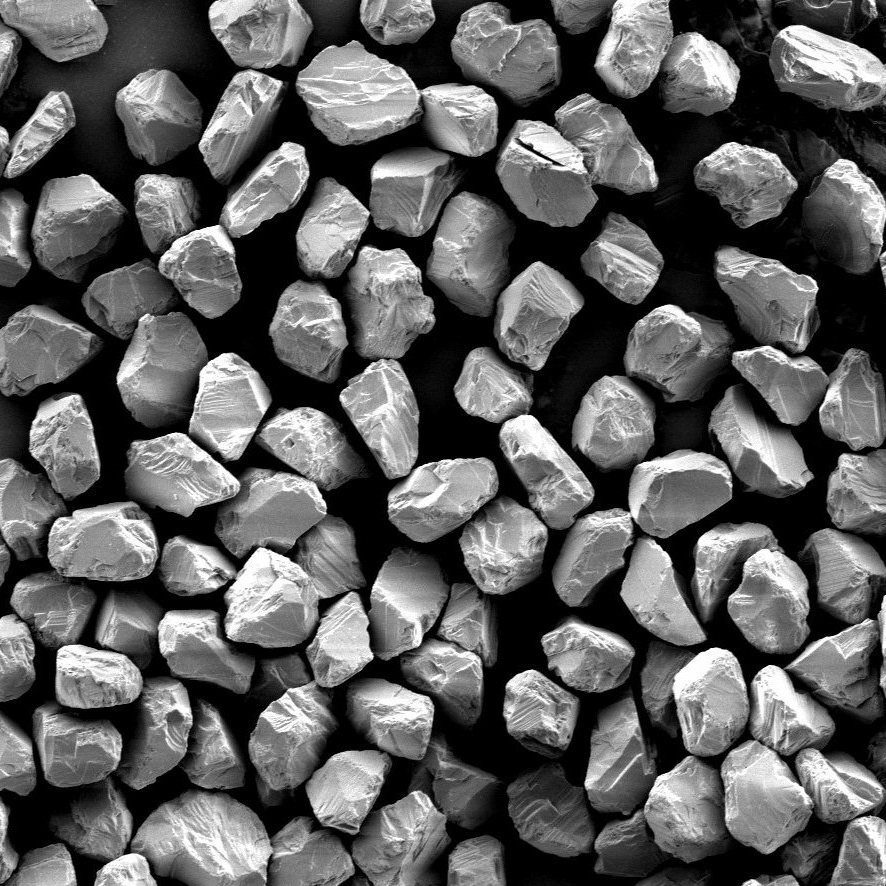

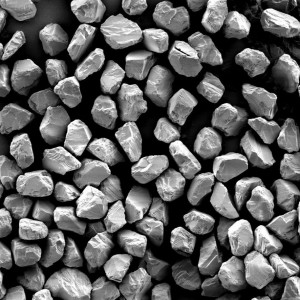

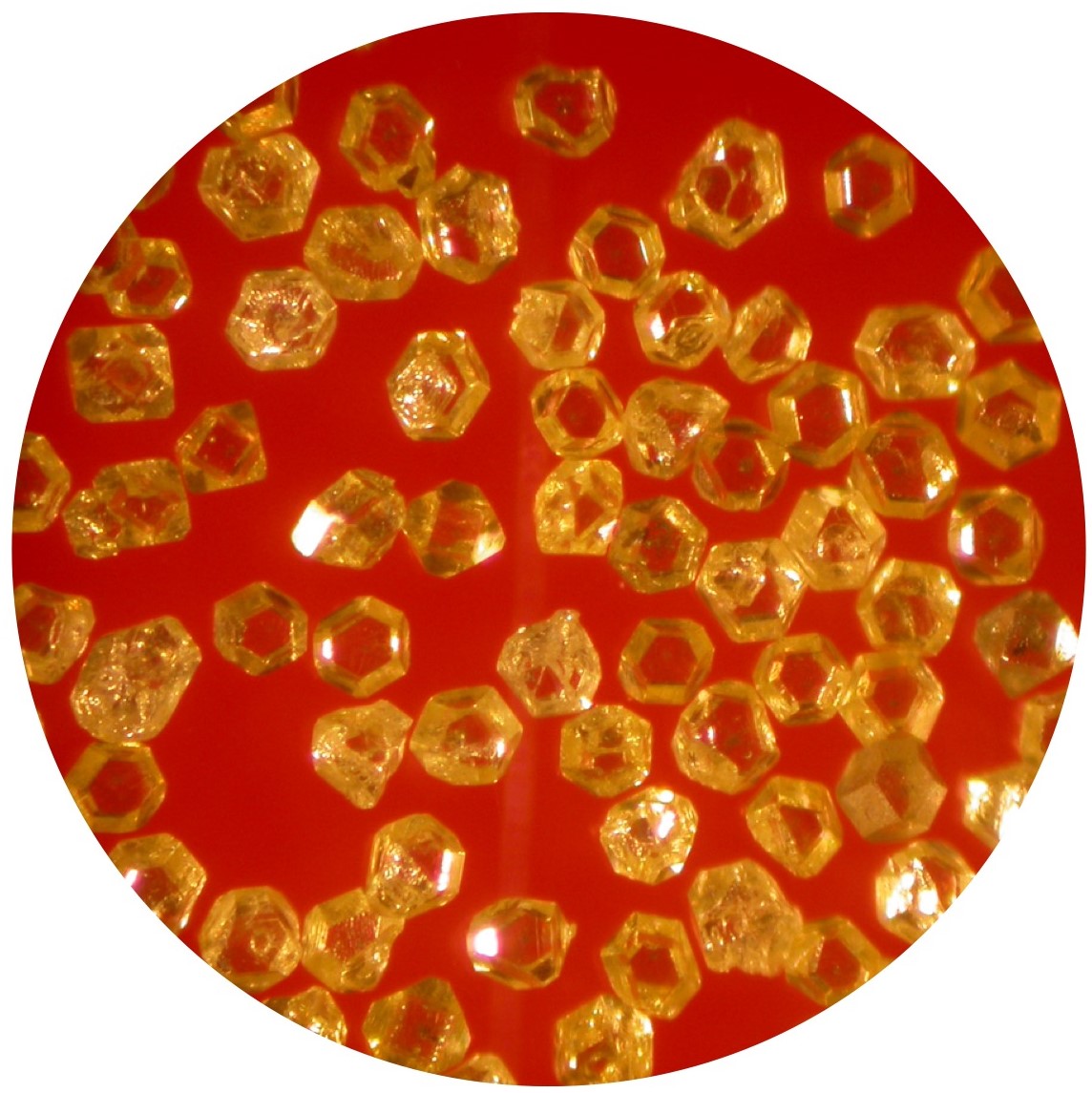

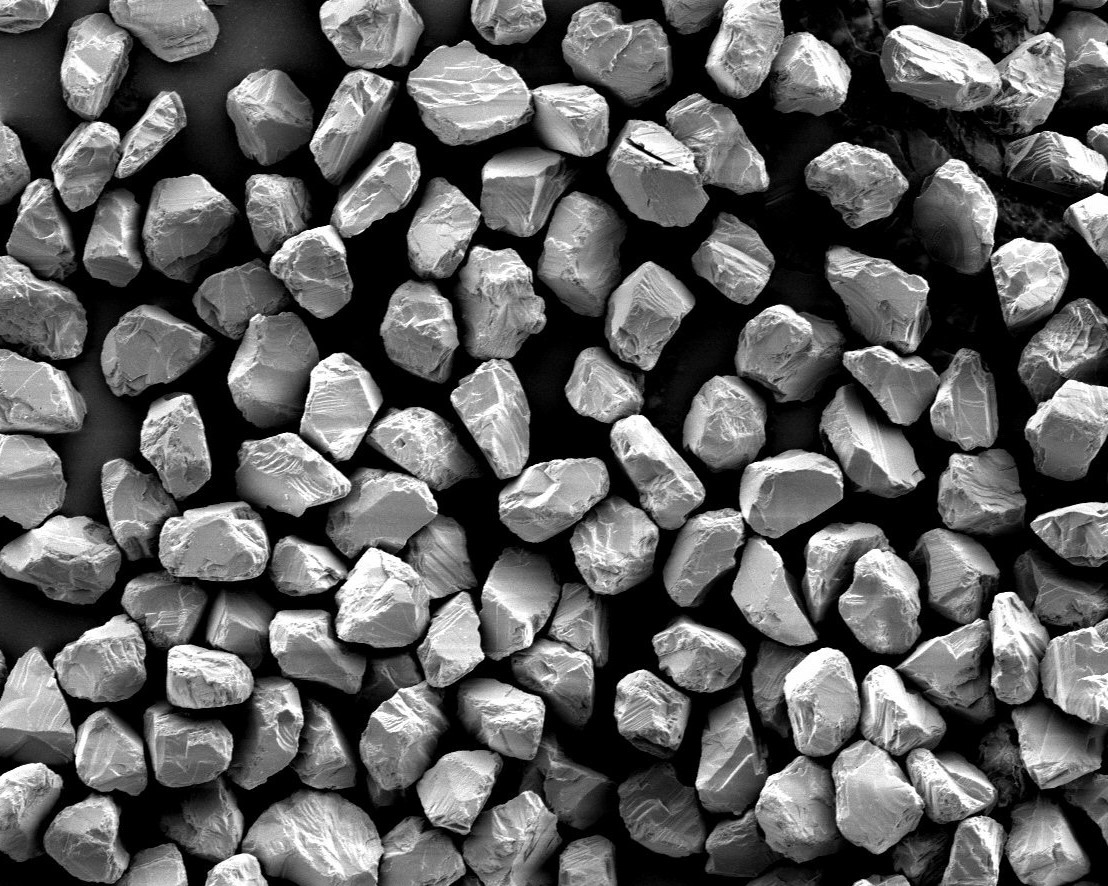

SND-MDW has a high strength blocky crystal shape, concentrated particle size distribution, Uniform particle size and shape. Specially designed for making silicon wafer cutting diamond wire, jewelry saw, semiconductor saw.

2. Specification of Micron Diamond Powder

|

|

|

| SND-M05 0-0.125~40-60 | SND-M10 0-0.125~40-60 | SND-M15 0-0.125~40-60 |

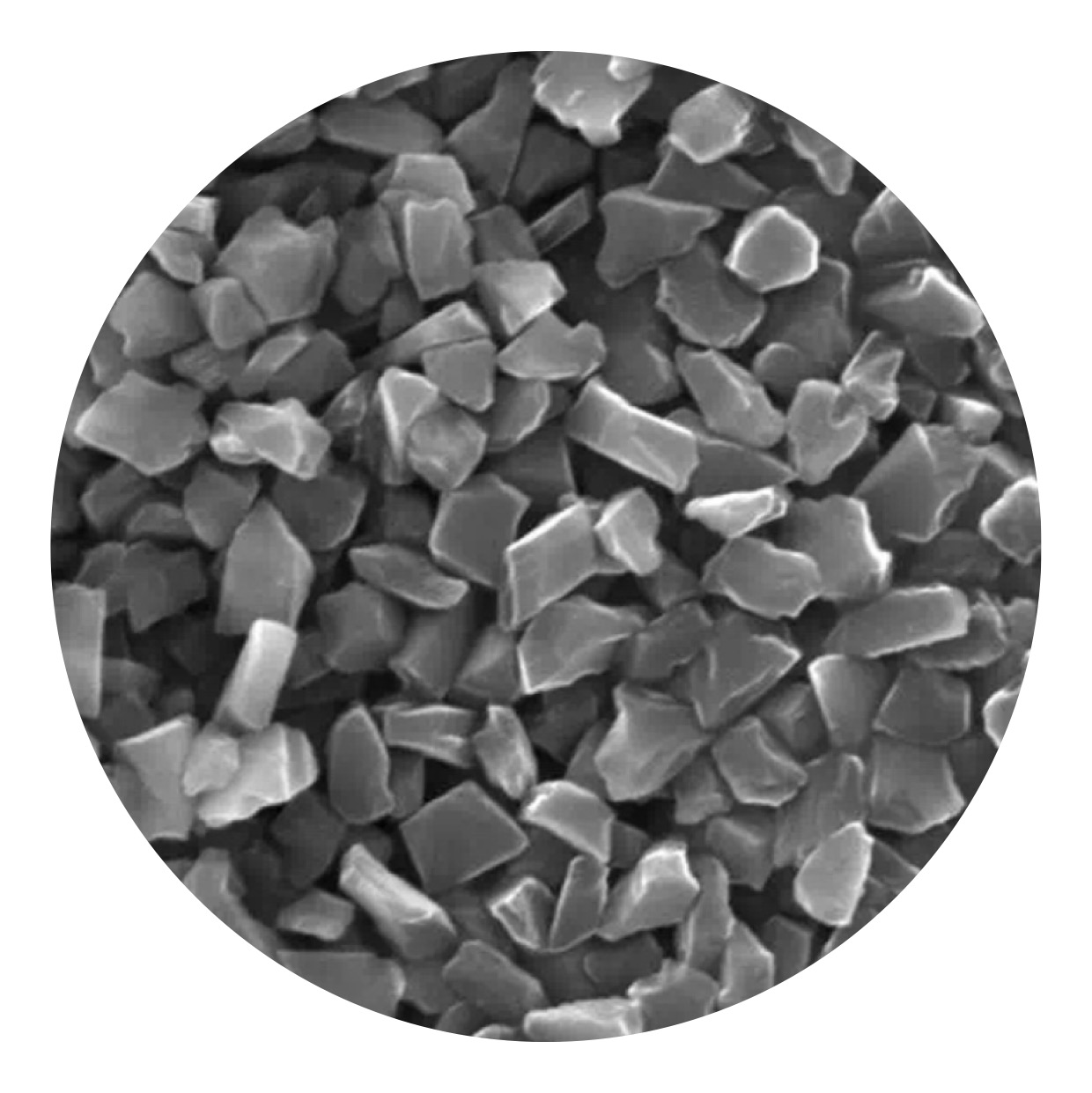

| Irregular crystal shape,

impurity content and particle size distribution, can be used in resin and vitrified bond. Suitable for high efficient grinding and polishing applications, like stones, tiles, Jade & gem, etc. |

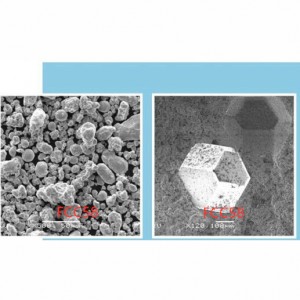

Irregular crystal shape with

relatively concentrated particle size distribution, low impurity content. High efficiency. Can be used in resin, vitrified, metal bond and electroplated products. |

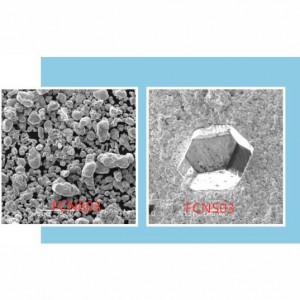

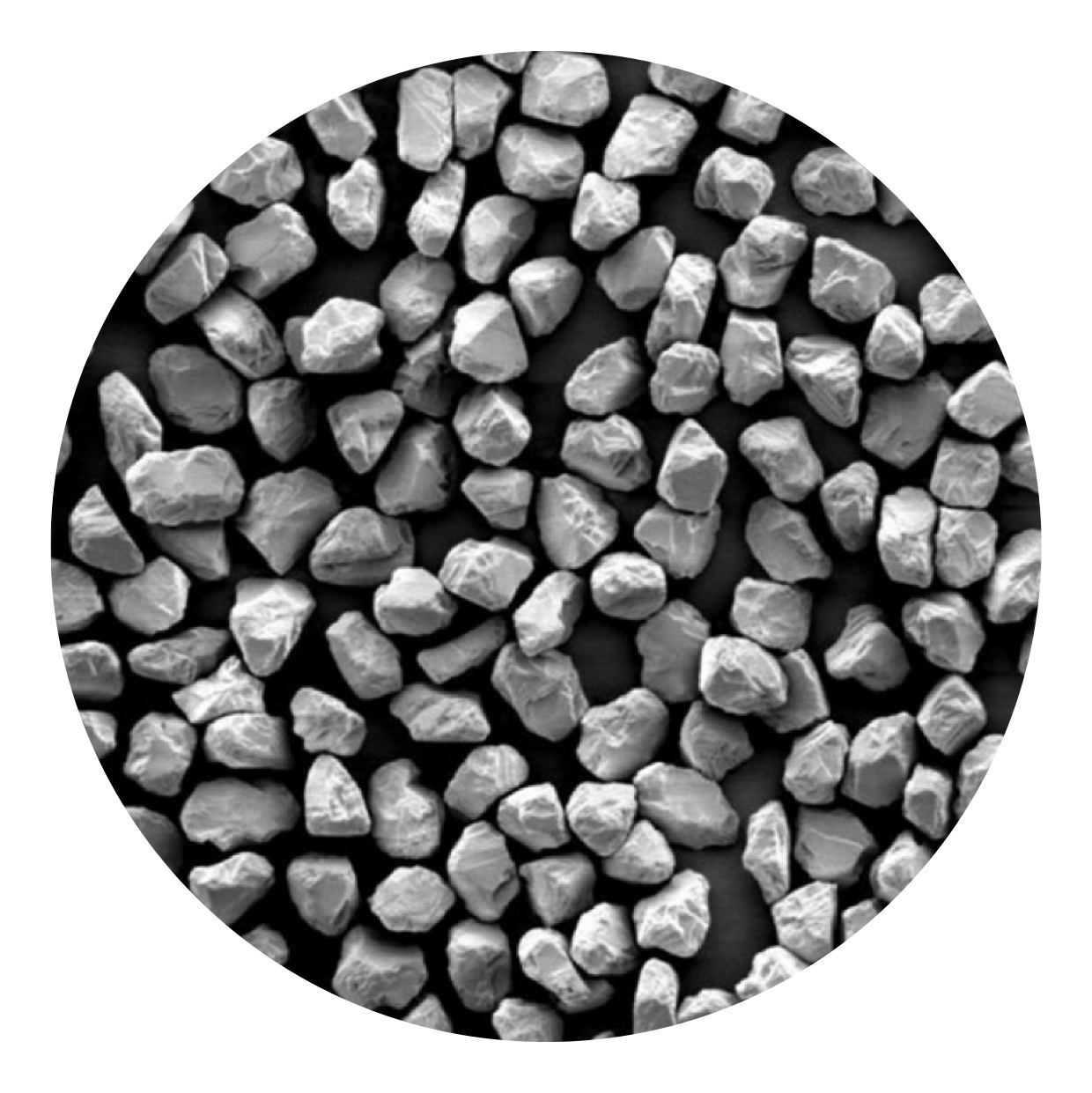

Block grain, relatively

concentrated particle size distribution, tiny impurities, favorable hydrophilic performance. Suitable for high requirement lapping, polishing, can be used for PCD high quality diamond paste and slurry and other high quality diamond products. |

|

|

|

| SND-M/DW 0-0.125~40-60 | SND-M/PCD 0-0.125~40-60 | SND-M/PL 0-0.125~40-60 |

| Uniform particle size and shape.

For making silicon wafer cutting diamond wire, jewelry saw, semiconductor saw. |

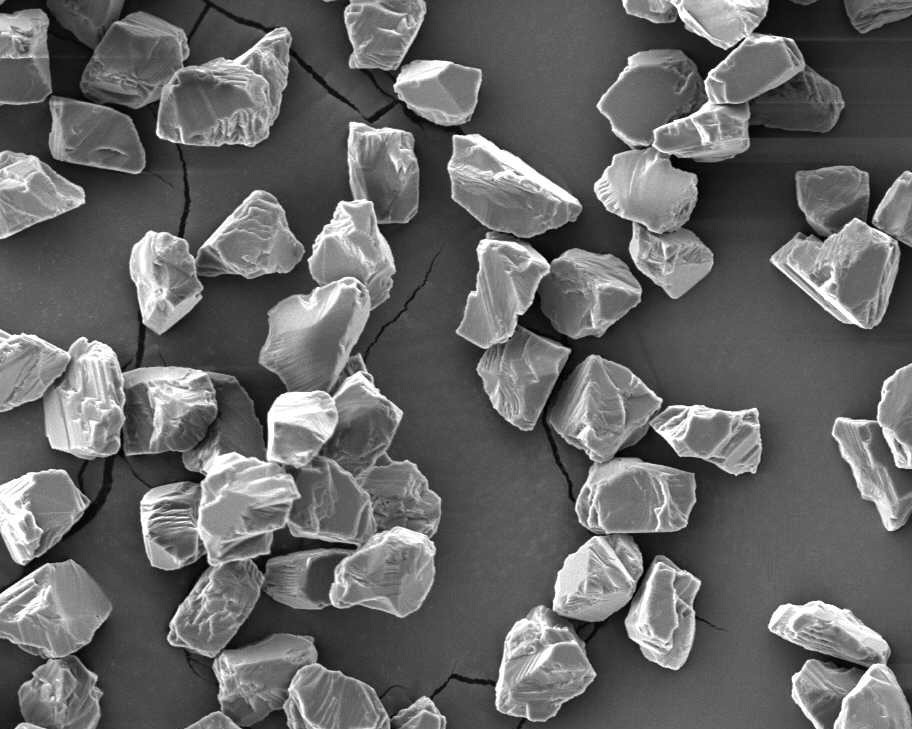

Specially designed for PCD/PDC application, high strength blocky crystal shape, concentrated particle size distribution, very low impurity, low Si content, good thermal stability and wear resistance. Also can be used on high quality metal bond, vitrified bond and electroplated products. |

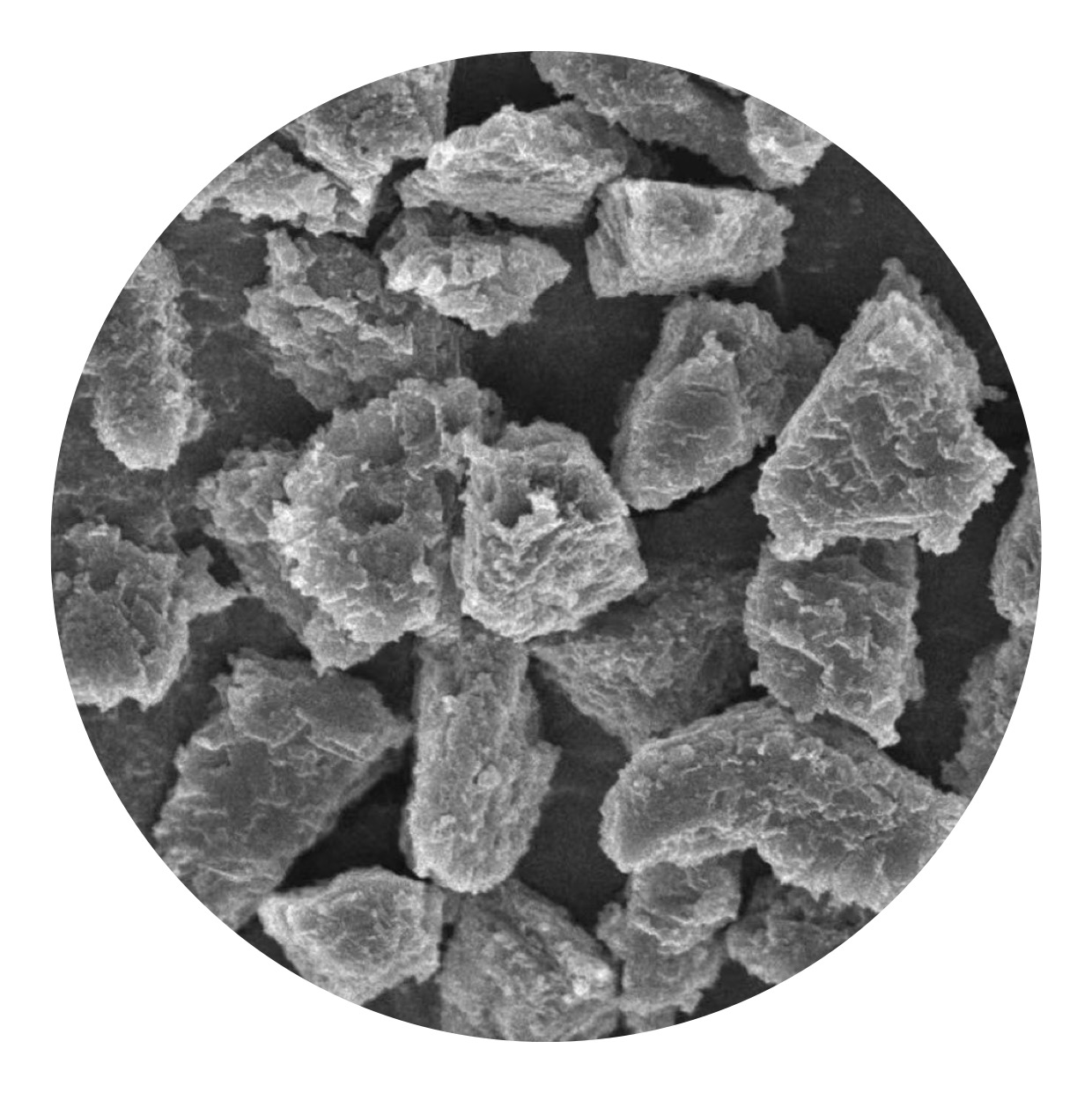

Poly-like diamond has the

similar feature as the polycrystalline diamond, but lower cost. It is made of the sorted diamond micron, with a special chemical treatment, the poly-like diamond has muti deavtivation edges, these honeycomb edges can help the polishing surface out of scratches. |

3. Micron Diamond Available Grit Size

| International Standard | China Standard | Mesh Size | Application |

| 0-0.1 | W0.1 | 100000 | Super Mirror Polishing |

| 0.0.25 | W0.25 | 60000 | Super Mirror Polishing |

| 0-0.5 | W0.5 | 30000 | Mirror Polishing |

| 0-1 | W1 | 15000 | Mirror Polishing |

| 0-2 | W1.5- | 13000 | Fine Polishing |

| 1-2 | W1.5 | 12000 | Fine Polishing |

| 1-3 | W2.5 | 10000 | Fine Polishing |

| 2-4 | W3.5 | 6500 | Fine Polishing |

| 2-5 | W4 | 5000 | Fine Polishing |

| 3-6 | W5 | 4000 | Fine Polishing |

| 4-6 | W6 | 3500 | Fine Polishing |

| 4-8 | W7 | 3000 | Normal Polishing |

| 4-9 | W10 | 2500 | Normal Polishing |

| 5-10 | W10 | 2000 | Normal Polishing |

| 6-12 | W10 | 1800 | Normal Polishing |

| 8-12 | W12 | 1600 | Normal Polishing |

| 7-14 | W14 | 1500 | Normal Polishing |

| 8-16 | W14 | 1300 | Normal Polishing |

| 10-20 | W20- | 1200 | Normal Polishing |

| 12-22 | W20 | 1000 | Normal Polishing |

| 15-25 | W20+ | 800 | Normal Polishing |

| 20-30 | W28 | 700 | Normal Polishing |

| 22-36 | W28+ | 600 | Rough Grinding |

| 20-40 | W40- | 500 | Rough Grinding |

| 30-40 | W40 | 450 | Rough Grinding |

| 35-45 | W40+ | 400 | Rough Grinding |

| 36-54 | W50 | 350 | Rough Grinding |

| D46 | 325/400 | 320 | Rough Grinding |

| D54 | 270/325 | 270 | Rough Grinding |

| D64 | 230/270 | 230 | Rough Grinding |

| D76 | 200/230 | 200 | Rough Grinding |

4. Other Coarse Grit Size

|

50/60-325/400 |

Light green color, irregular shape with lower toughness. Widely used for processing stones, concretes, ceramics, etc. |

|

|

30/35-325/400 |

Yellow color, irregular shape with a standard hardness, Applied in ceramic bonded, resin bonded and all kinds of electroplating products, for processing stones, hard alloy, magnetic materials, natural diamond, gem. |

|

|

30/35-325/400 |

Yellow color, high hardness and toughness. Applied in ceramic bond,resin bond and all kinds of electroplating products, can be used for heavy duty processing on carbide, glass, ceramics, stone and other non-metallic materials. |

|

|

80/100-325/400 |

Mix of regular and angular crystals, medium-low toughness with blocky shaped crystals. It is suitable for the application of high efficiency diamond tools. |

|

|

80/100-325/400 |

Medium touhness with a better diamond shpe. Suitable for the diamond tools of beveling glass or crystal, grinding of carbide and magnetic materials, etc. |

|

|

80/100-325/400 |

Medium high toughness with regular shape, good high thermal stability and impact resistance. Applied to make grinding & abrasives wheels to process medium load materials, like core drilling of glass, pencil edging, and engraving decorative glass and crystal. |

|

|

80/100-325/400 |

Certain of cubooctahedral shape, high impact strength and thermal stability. Applied in the condition requiring high grinding rate, like electroplated tools to grind and polish stones, ceramics, glasses, and magnetic materials, etc. |