SND-M15 High Toughness Synthetic Micron Diamond Powder Polishing Abrasive

SND-M15 High Toughness Synthetic Micron Diamond Powder Polishing Abrasive

1. Micron Diamond Powder Introduction

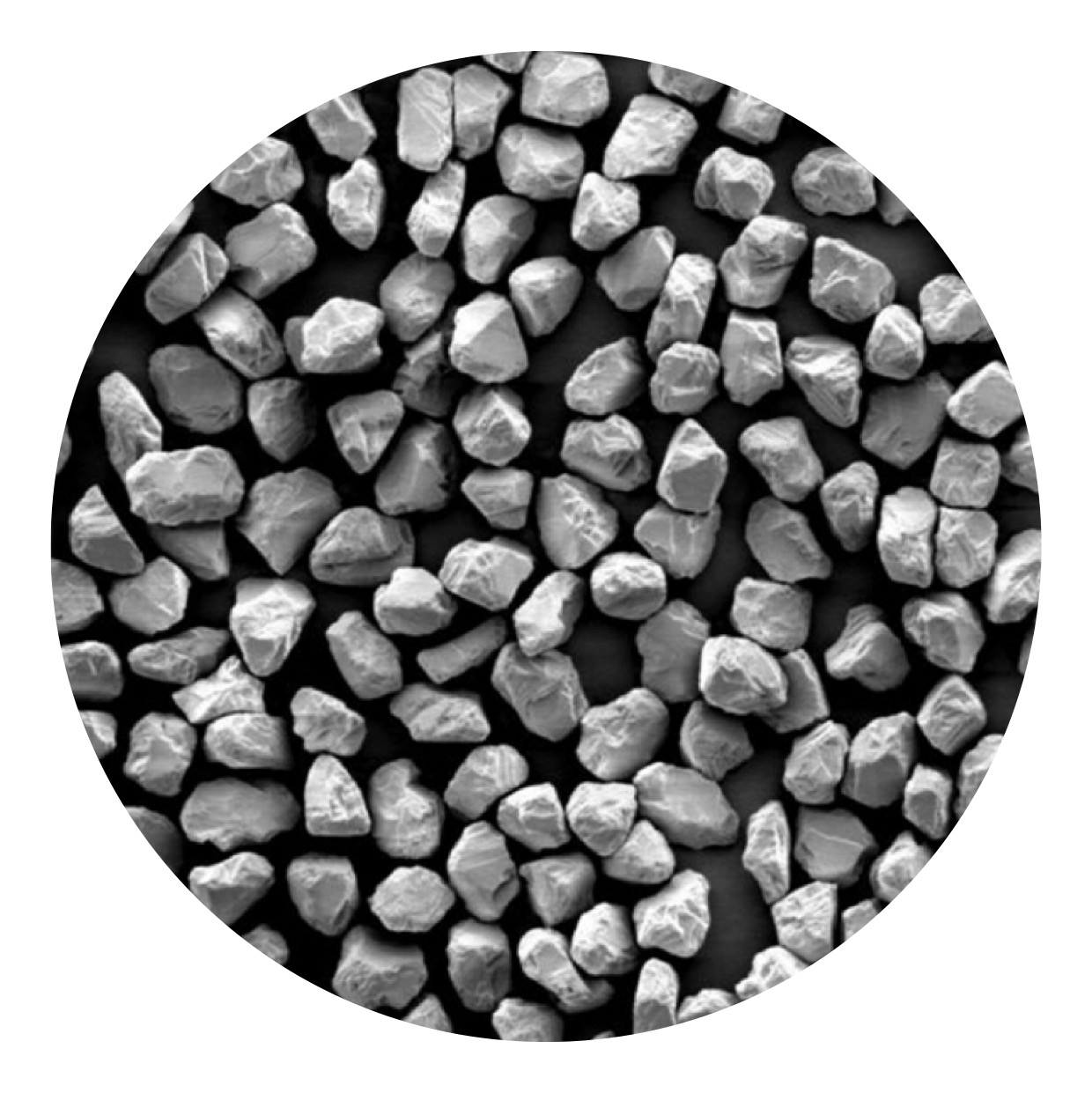

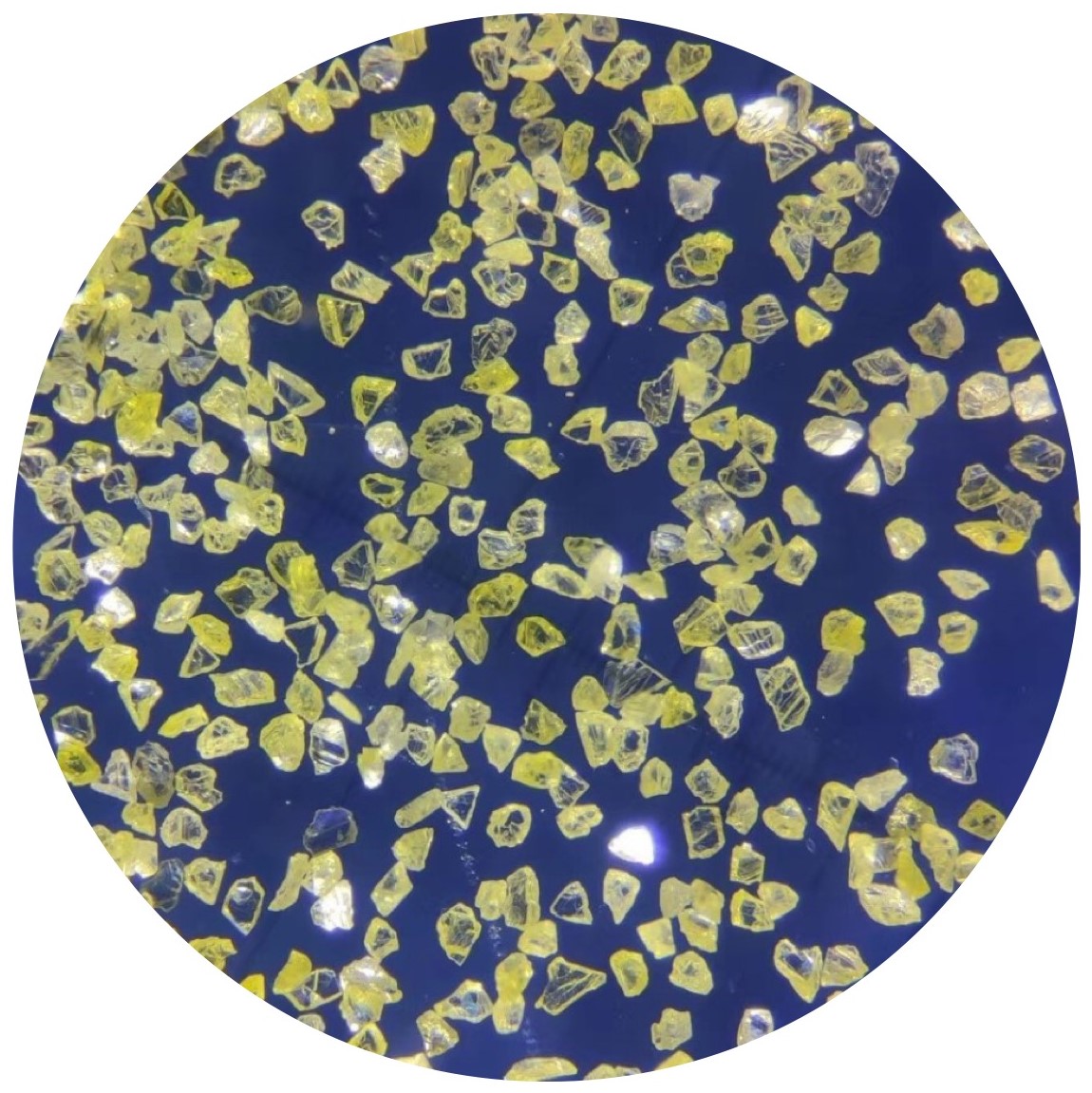

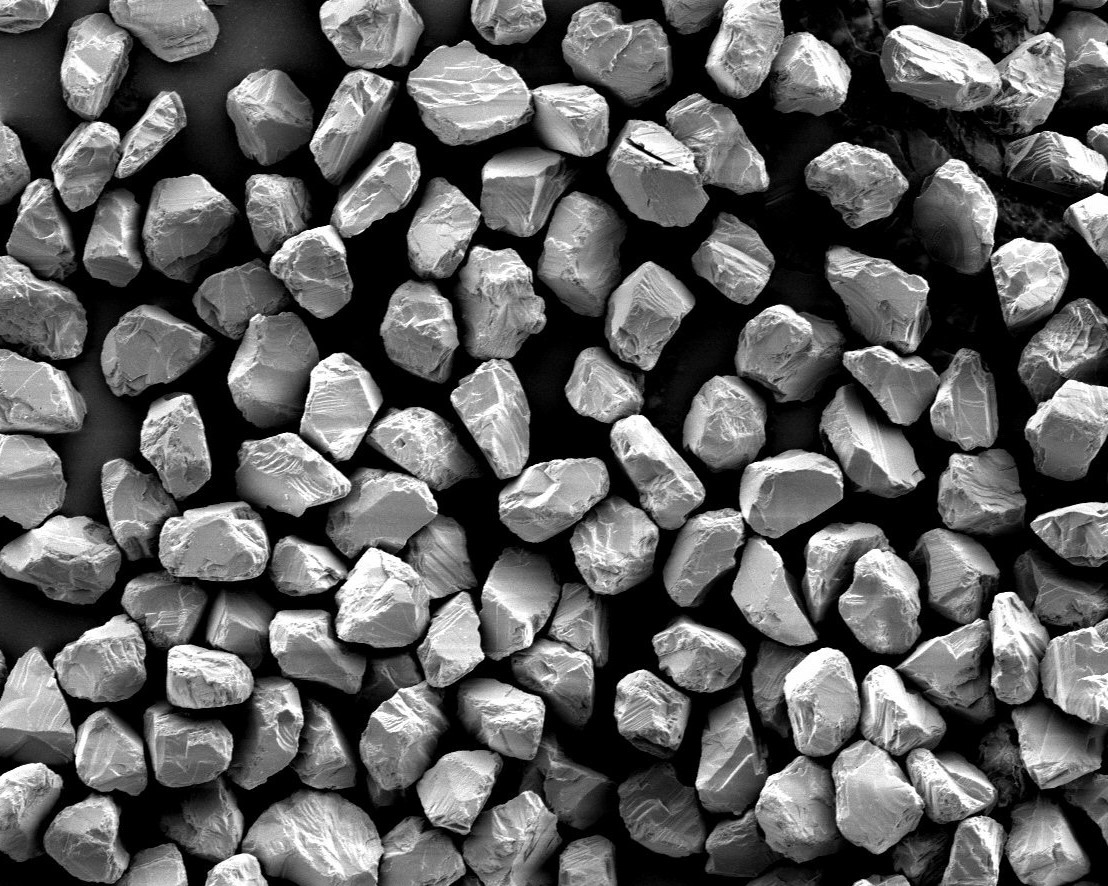

SND-M15 is high quality high toughness micron diamond powder, with block grain, relatively concentrated particle size distribution, tiny impurities, favorable hydrophilic performance. Suitable for high requirement lapping, polishing, can be used for PCD high quality diamond paste and slurry and other high quality diamond products.

2. Specification of Micron Diamond Powder

|

|

|

| SND-M05 0-0.125~40-60 | SND-M10 0-0.125~40-60 | SND-M15 0-0.125~40-60 |

|

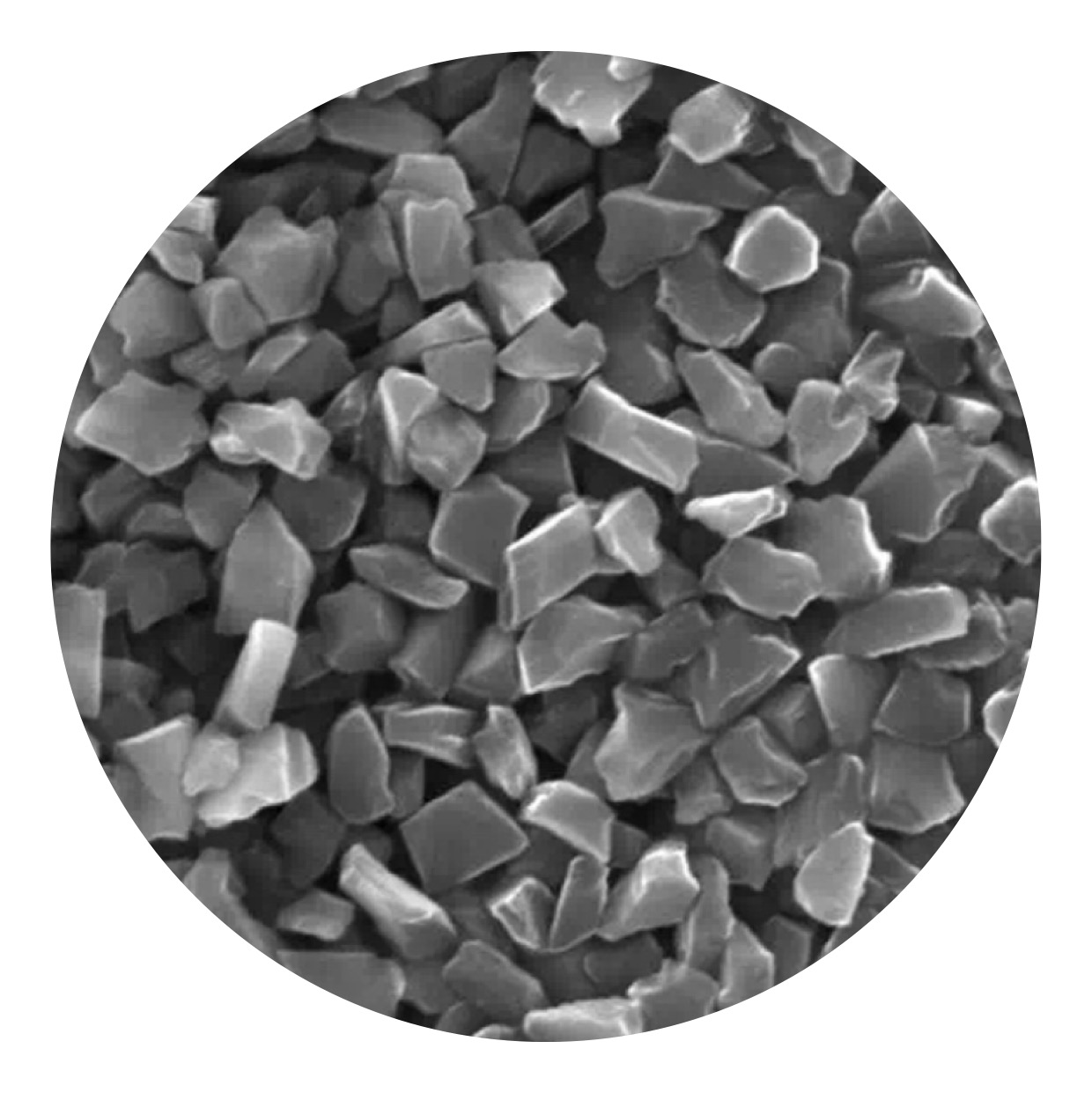

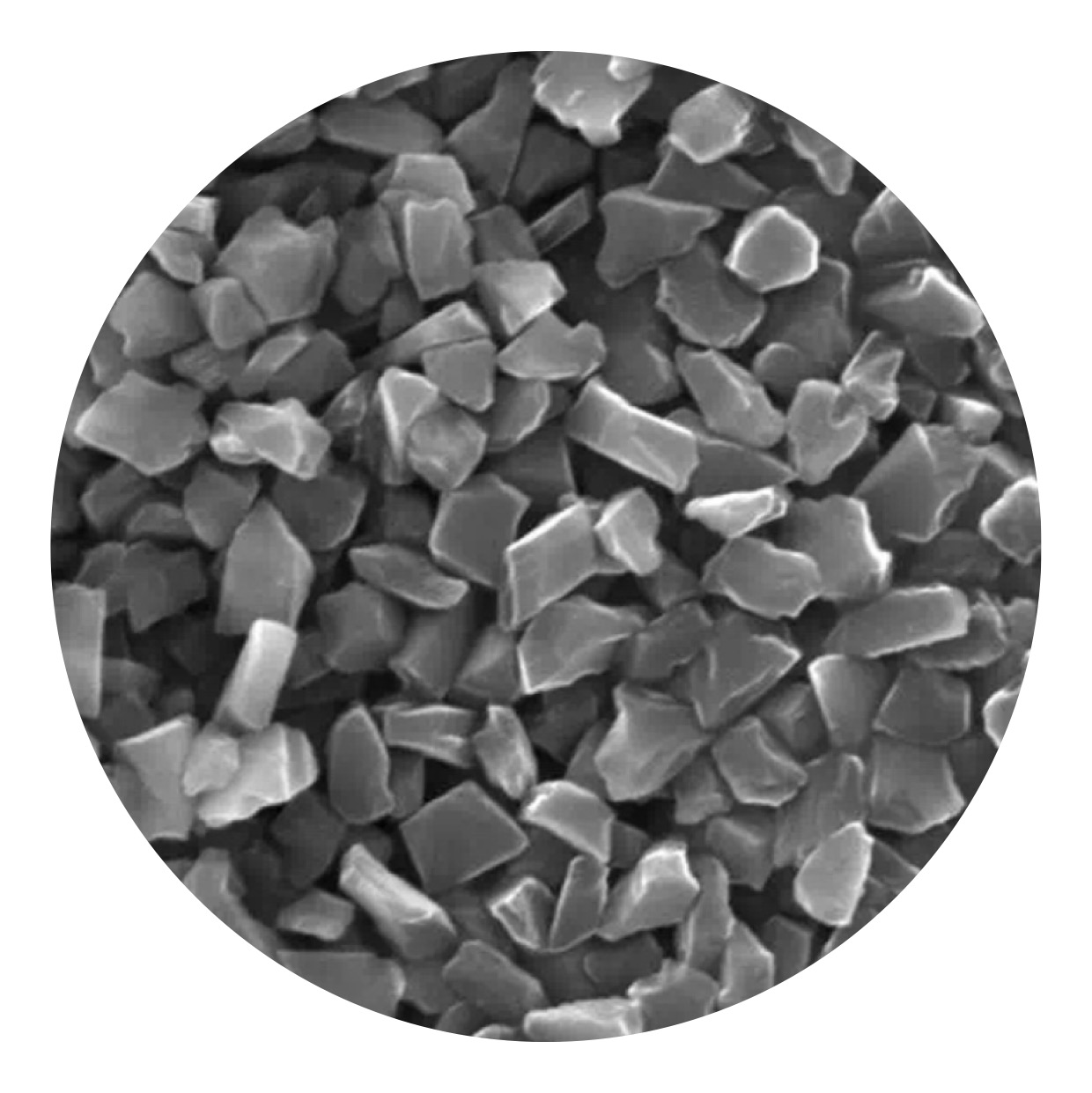

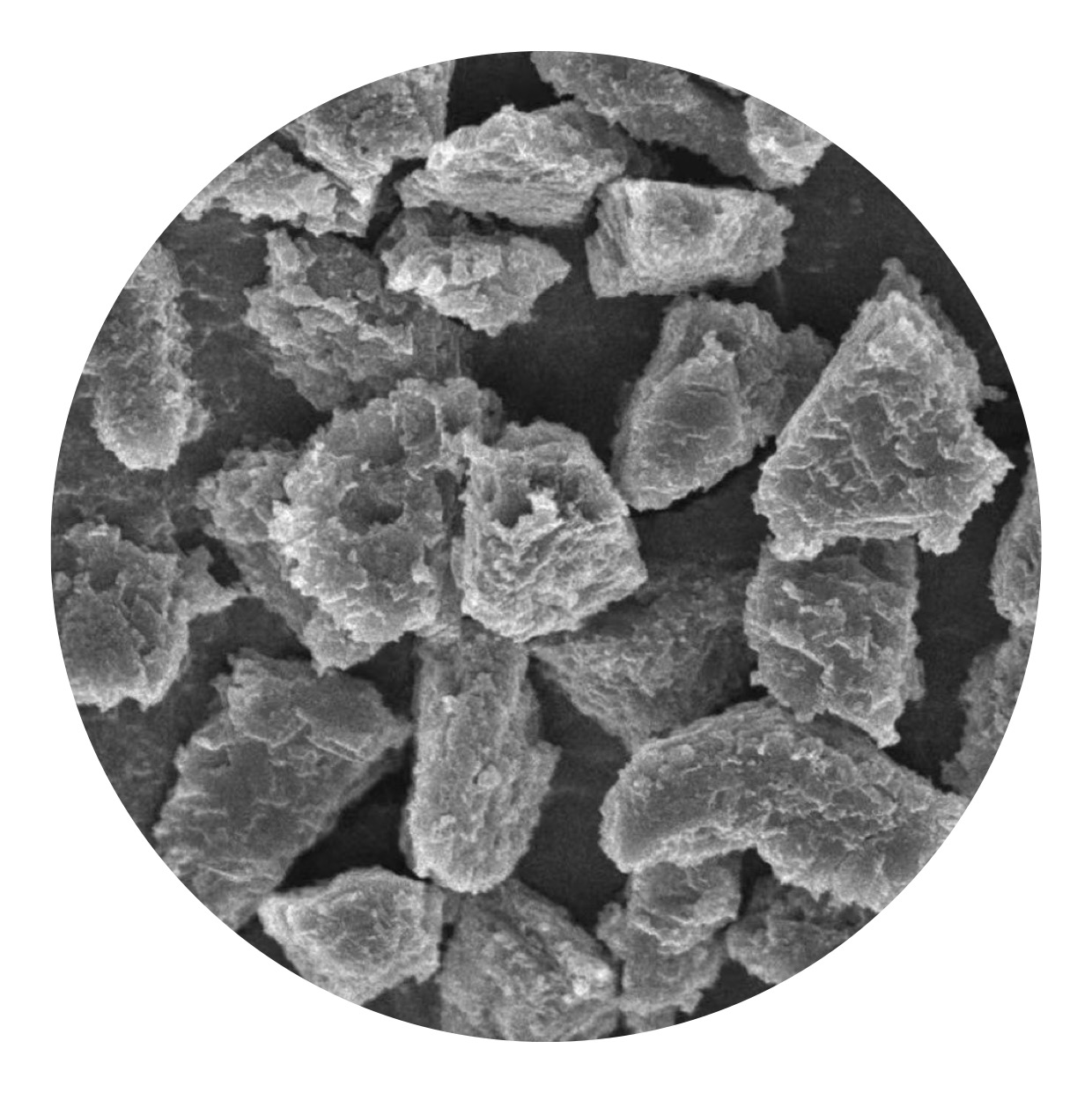

Irregular crystal shape, impurity content and particle size distribution, can be used in resin and vitrified bond. Suitable for high efficient grinding and polishing applications, like stones, tiles, Jade & gem, etc. |

Irregular crystal shape with relatively concentrated particle size distribution, low impurity content. High efficiency. Can be used in resin, vitrified, metal bond and electroplated products. |

Block grain, relatively concentrated particle size distribution, tiny impurities, favorable hydrophilic performance. Suitable for high requirement lapping, polishing, can be used for PCD high quality diamond paste and slurry and other high quality diamond products. |

|

|

|

| SND-M/DW 0-0.125~40-60 | SND-M/PCD 0-0.125~40-60 | SND-M/PL 0-0.125~40-60 |

|

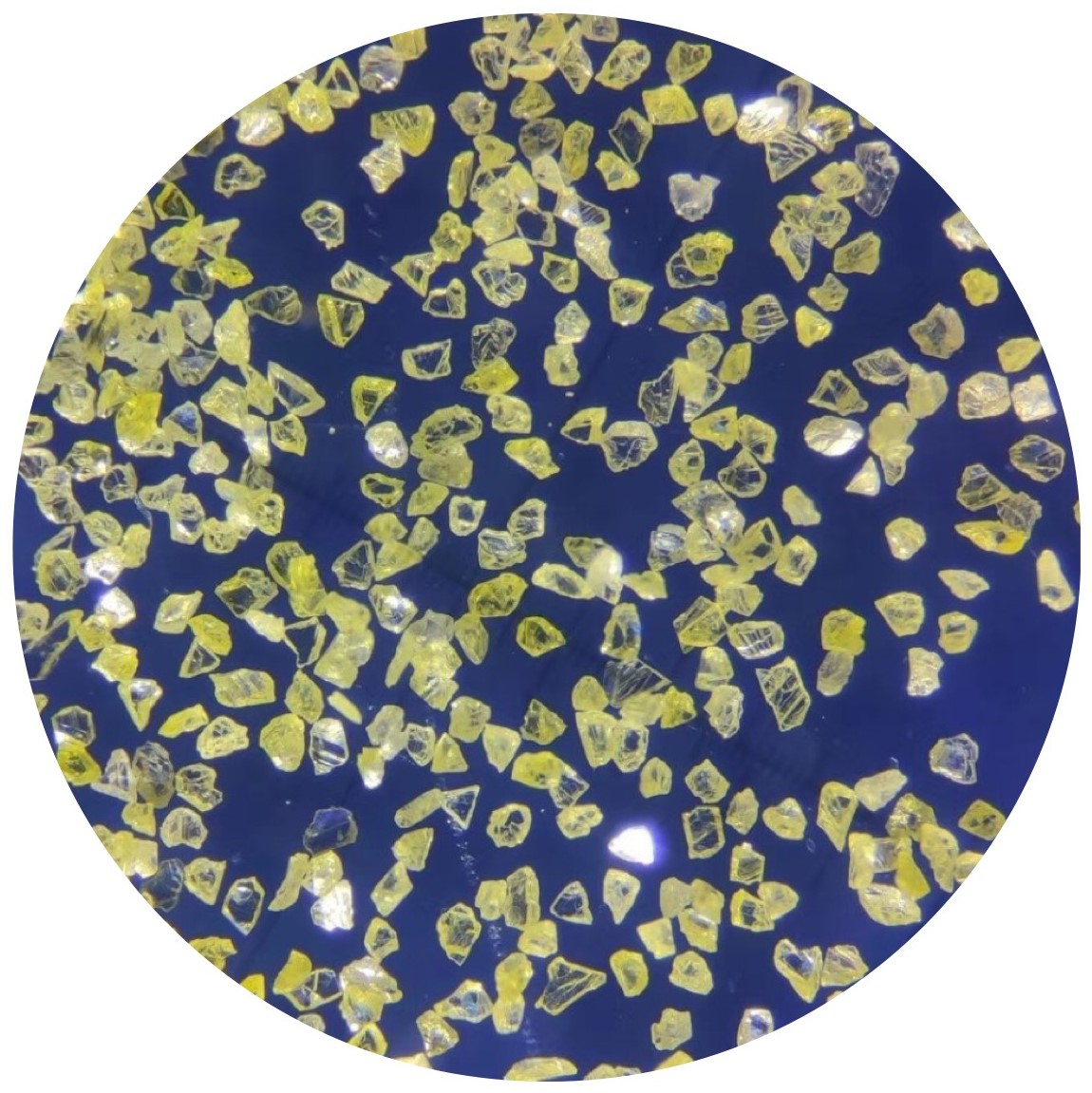

Uniform particle size and shape. Formaking silicon wafer cutting diamond wire, jewelry saw, semiconductor saw. |

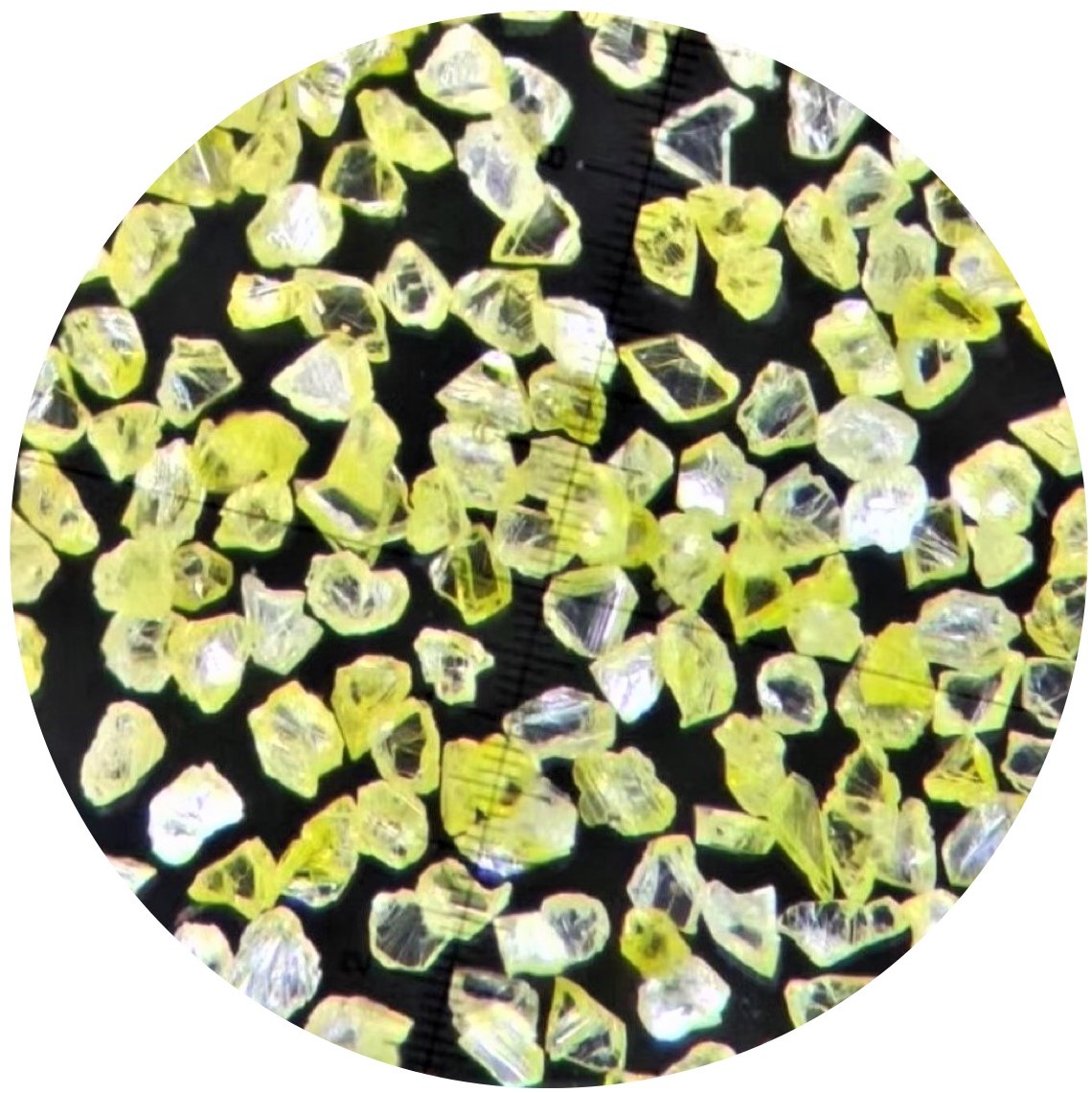

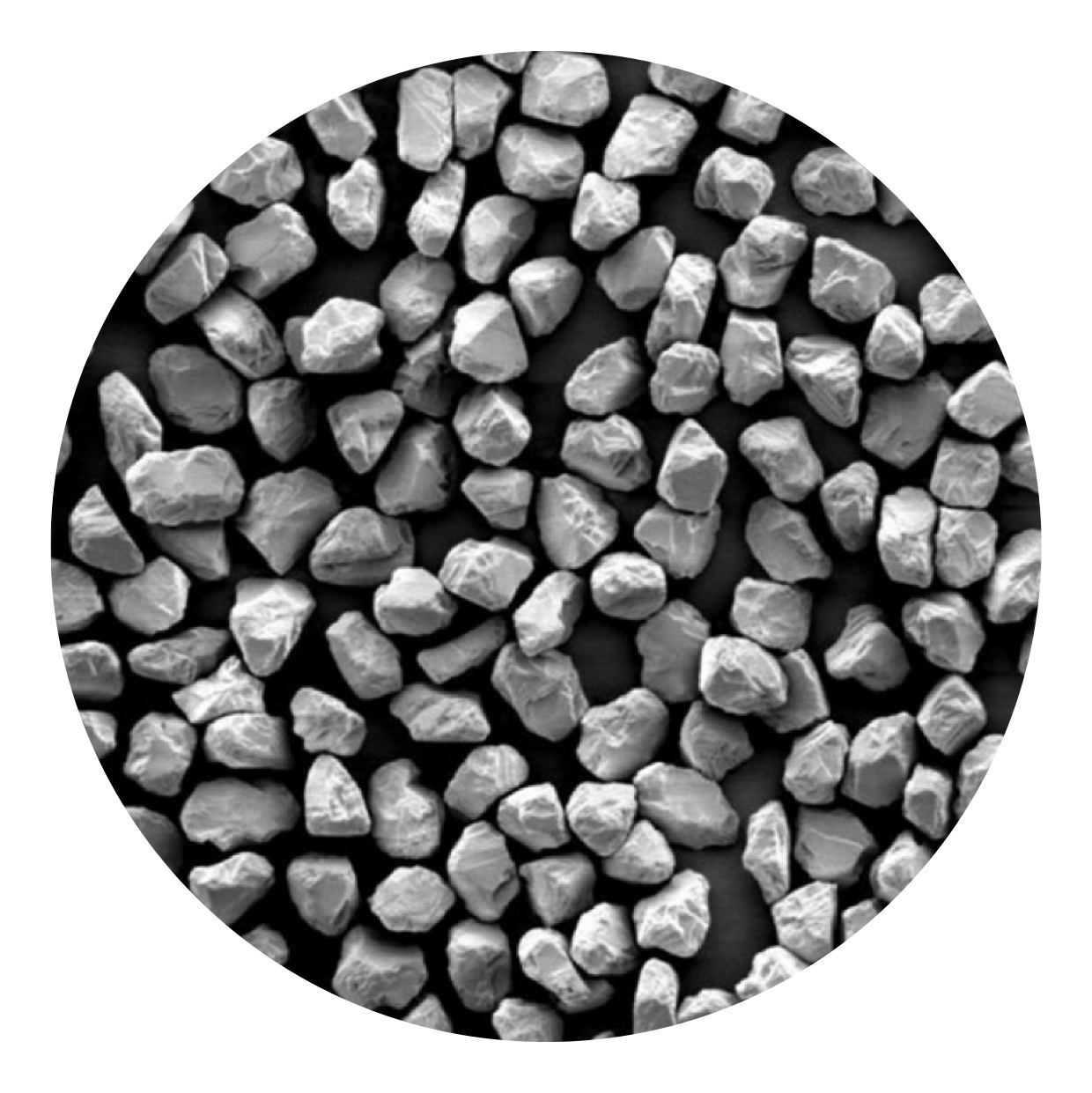

Specially designed for PCD/PDC application, high strength blocky crystal shape, concentrated particle size distribution, very low impurity, low Si content, good thermal stability and wear resistance. Also can be used on high quality metal bond, vitrified bond and electroplated products. |

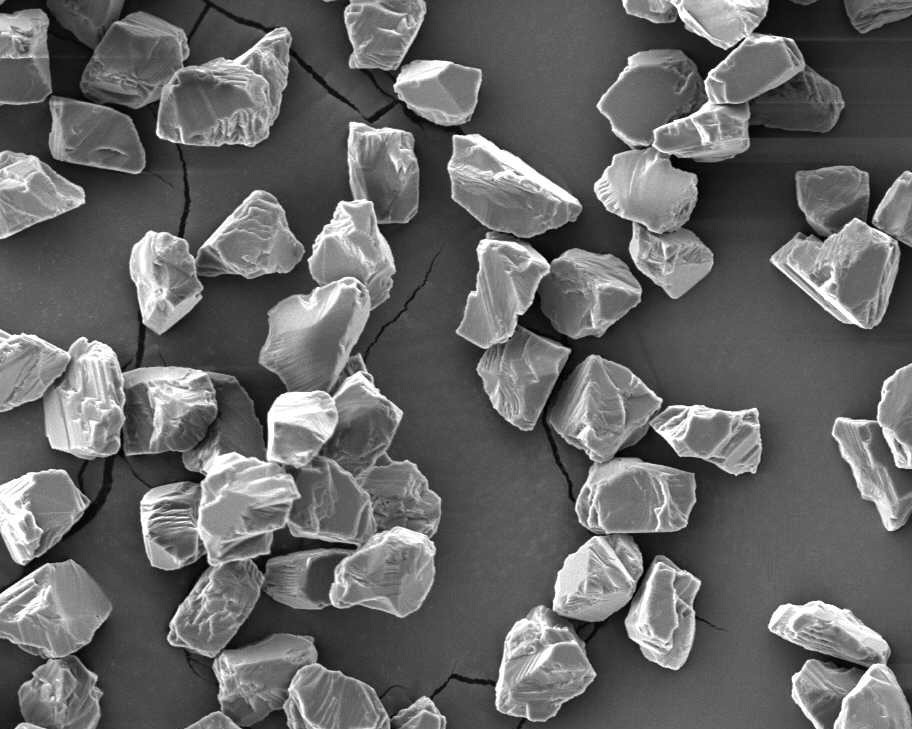

Poly-like diamond has the similar feature as the polycrystalline diamond, but lower cost. It is made of the sorted diamond micron, with a special chemical treatment, the poly-like diamond has muti deavtivation edges, these honeycomb edges can help the polishing surface out of scratches. |

3. Micron Diamond Available Grit Size

| International Standard | China Standard | Mesh Size | Application |

| 0-0.1 | W0.1 | 100000 | Super Mirror Polishing |

| 0.0.25 | W0.25 | 60000 | Super Mirror Polishing |

| 0-0.5 | W0.5 | 30000 | Mirror Polishing |

| 0-1 | W1 | 15000 | Mirror Polishing |

| 0-2 | W1.5- | 13000 | Fine Polishing |

| 1-2 | W1.5 | 12000 | Fine Polishing |

| 1-3 | W2.5 | 10000 | Fine Polishing |

| 2-4 | W3.5 | 6500 | Fine Polishing |

| 2-5 | W4 | 5000 | Fine Polishing |

| 3-6 | W5 | 4000 | Fine Polishing |

| 4-6 | W6 | 3500 | Fine Polishing |

| 4-8 | W7 | 3000 | Normal Polishing |

| 4-9 | W10 | 2500 | Normal Polishing |

| 5-10 | W10 | 2000 | Normal Polishing |

| 6-12 | W10 | 1800 | Normal Polishing |

| 8-12 | W12 | 1600 | Normal Polishing |

| 7-14 | W14 | 1500 | Normal Polishing |

| 8-16 | W14 | 1300 | Normal Polishing |

| 10-20 | W20- | 1200 | Normal Polishing |

| 12-22 | W20 | 1000 | Normal Polishing |

| 15-25 | W20+ | 800 | Normal Polishing |

| 20-30 | W28 | 700 | Normal Polishing |

| 22-36 | W28+ | 600 | Rough Grinding |

| 20-40 | W40- | 500 | Rough Grinding |

| 30-40 | W40 | 450 | Rough Grinding |

| 35-45 | W40+ | 400 | Rough Grinding |

| 36-54 | W50 | 350 | Rough Grinding |

| D46 | 325/400 | 320 | Rough Grinding |

| D54 | 270/325 | 270 | Rough Grinding |

| D64 | 230/270 | 230 | Rough Grinding |

| D76 | 200/230 | 200 | Rough Grinding |