Short Lead Time for Rough Cut Diamond - Diamond Lapping Abrasive Paste Diamond Compound for Polishing – SinoDiam

Short Lead Time for Rough Cut Diamond - Diamond Lapping Abrasive Paste Diamond Compound for Polishing – SinoDiam Detail:

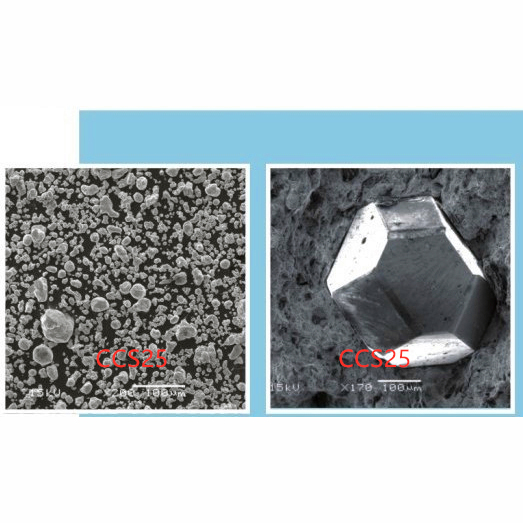

Polycrystalline diamond paste for precision polishing, Oil soluble.

Good wettability, strong grinding force, suitable for processing of equipment, measuring devices, knives,

grinding tools and seals that are made from super hard materials like hard alloy, alloy steel and carbon

steel.

- Name: Diamond Polishing Compound

- Brand: SND-PC

- Mesh: 0-0.25~40-60

- Diamond Percentage: 10%, 25%, 50%

- Application: Suitable for the grinding and polishing of metals, tungsten carbide, mold, alloys, glass, ceramics, semiconductors, jade, and other hard

materials. - Package: 5g syringe/10g/50g plastic bottles/upon request.

Available Size and Application

|

Synthetic diamond micro powder (µm) |

Mesh |

Usage |

|

|

W0.25 |

(0-0.5) |

#60,000 |

For Super mirror polishing |

|

W0.5 |

(0-1) |

#28,000 |

|

|

W1 |

(0-2) |

#14,000 |

|

|

W3 |

(2-4) |

#8,000 |

|

|

W4.5 |

(3-6) |

#5,000 |

For Precision brightness |

|

W6 |

(4-8) |

#3,000 |

|

|

W8 |

(6-10) |

#2,000 |

|

|

W9 |

(6-12) |

#1,800 |

|

|

W13 |

(10-16) |

#1,500 |

For General brightness |

|

W15 |

(10-20) |

#1,200 |

|

|

W17.5 |

(15-20) |

#1,000 |

|

|

W25 |

(20-30) |

#800 |

For Coarse grinding |

|

W35 |

(30-40) |

#600 |

|

|

W50 |

(40-60) |

#400 |

|

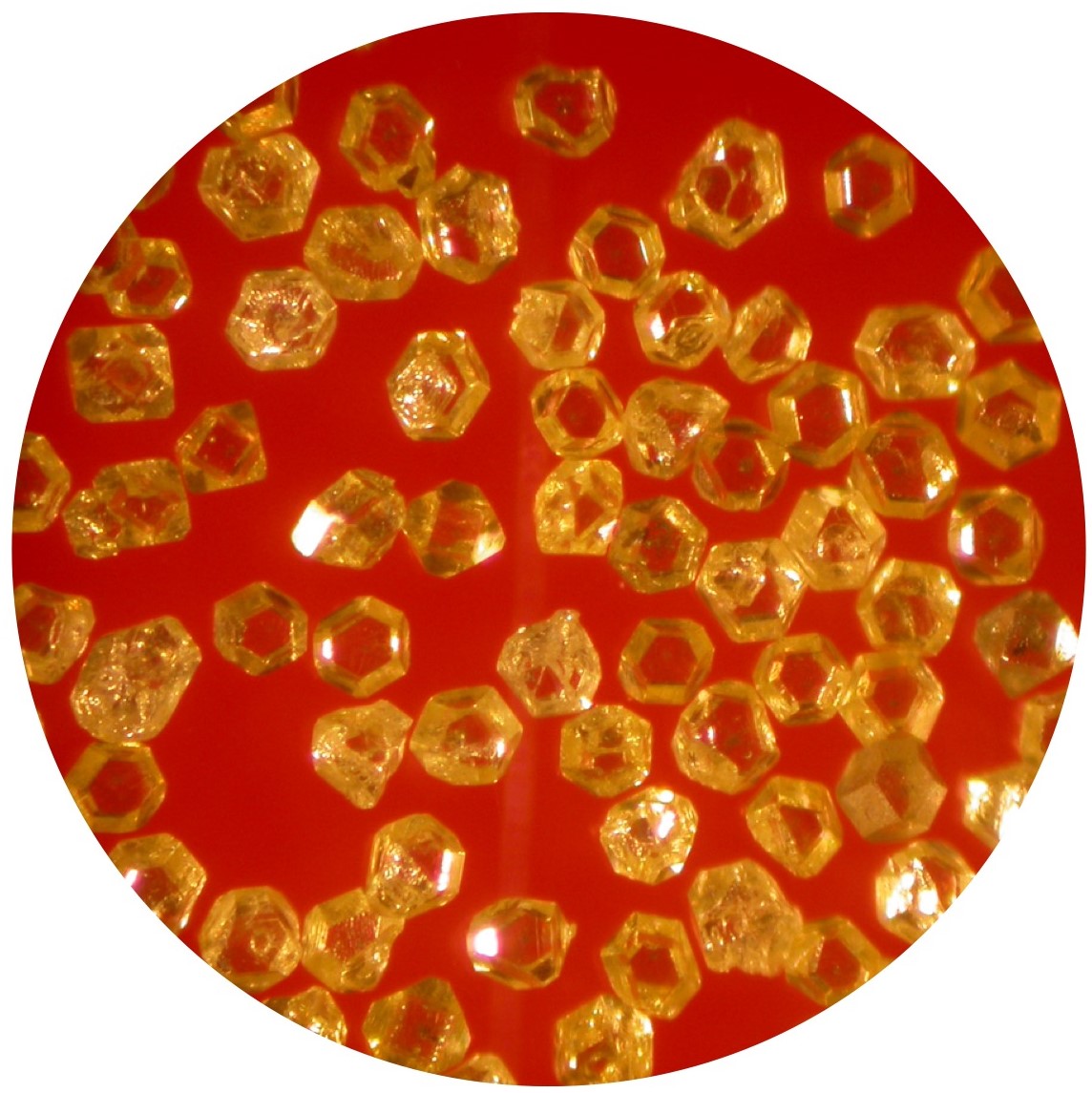

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for Short Lead Time for Rough Cut Diamond - Diamond Lapping Abrasive Paste Diamond Compound for Polishing – SinoDiam , The product will supply to all over the world, such as: Guyana, Mali, Manchester, "Good quality, Good service " is always our tenet and credo. We take every effort to control the quality, package, labels etc and our QC will check every detail during producing and before shipment. We are willing to establish long business relationship with those who seek the high quality products and good service. We have set up a wide sales network across European countries, North of America, South of America, Middle East, Africa, East Asia countries.Please contact us now, you will find our professional experience and high quality grades will contribute to your business.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

Write your message here and send it to us