SND-M15 Micron Diamond: Premium Precision for Lapping, Polishing & PCD Manufacturing

Description

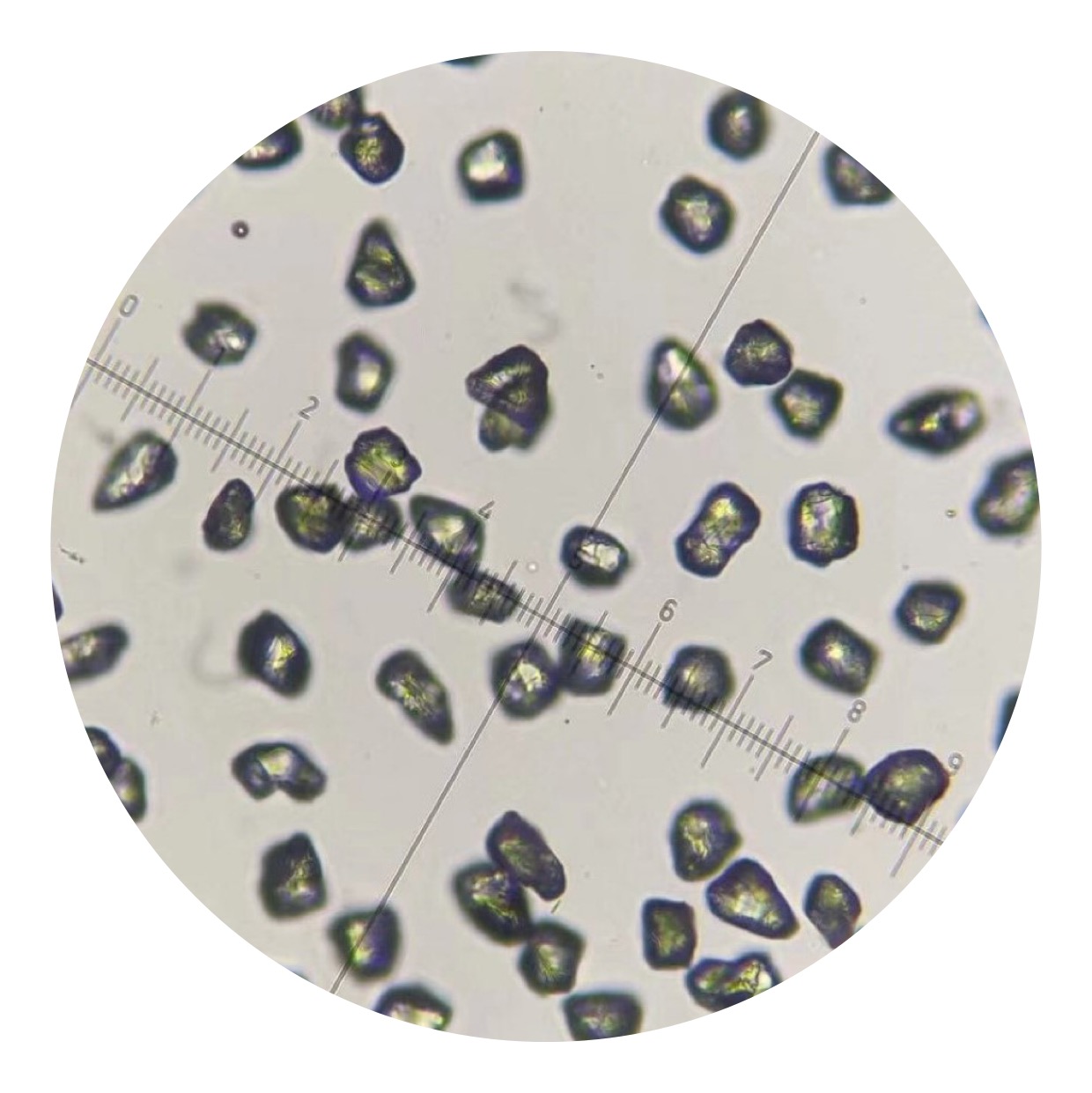

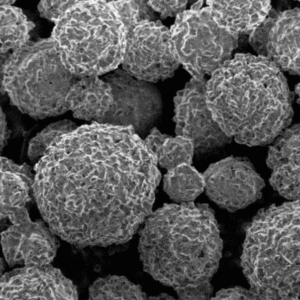

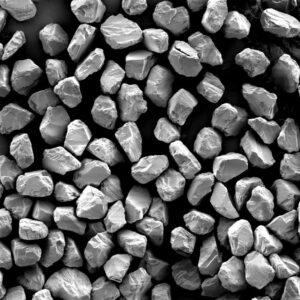

SND-M15 is crafted with blocky crystal grains that provide enhanced durability and uniformity in high-precision tasks. Featuring a tightly concentrated particle size distribution (0–0.125~40–60μm) and ultra-low impurities (total impurities ≤0.1%, nitrogen ≤0.05%, boron ≤0.02%), this premium diamond ensures exceptional surface quality and material removal rates. The hydrophilic properties improve dispersion in water-based slurries, enhancing performance in automated polishing systems. Ideal for industries such as aerospace, optical glass, and luxury gemstone polishing, SND-M15 sets the benchmark for micron diamond performance.

Technical Edge & Engineering

- Crystal & Impurity Mastery: The blocky crystal structure resists fracturing under high pressure, ensuring superior performance in tough lapping and polishing applications. Ultra-low impurity content prevents optical discoloration and ensures consistent electrical properties for PCD tools.

- Particle Size Distribution (PSD): With a tightly controlled PSD (variance ≤5%), SND-M15 ensures each grain contributes uniformly to material removal, reducing surface imperfections by 35% compared to mid-tier diamonds. This is critical for applications requiring mirror-like finishes.

- Thermal Stability & Wear Rate: SND-M15 withstands temperatures up to 850°C, making it ideal for metal and electroplated bonds used in high-heat tasks. Its ultra-low wear rate (0.3–0.5% mass loss per hour) ensures 2–3 times longer tool life compared to premium generic diamonds, cutting replacement costs and downtime.

Key Advantages

- Precision Beyond Compare: Achieves Ra ≤0.2μm surface finishes, essential for aerospace components (e.g., turbine blades), optical glass (e.g., camera lenses), and luxury gemstones. In optical glass polishing, it eliminates the need for secondary buffing, cutting processing time by 40%.

- Industry-Leading Durability: Lasts 2–3 times longer than SND-M10 in high-load applications like PCD tool lapping. For instance, a metal-bonded wheel with SND-M15 can polish 500+ PCD cutting inserts compared to just 200–250 with SND-M10, significantly reducing downtime for manufacturers.

- Optimized for High-End Bond Systems: Works seamlessly with premium metal bonds, advanced electroplating, and PCD paste/slurry formulations. Its hydrophilic properties ensure excellent grit dispersion in water-based slurries, critical for consistent performance in automated polishing systems.

Core Applications Across Industries

- Aerospace & Precision Engineering:

- Turbine Blade Polishing: Polishes aluminum and titanium turbine blades (Ra ≤0.2μm) to reduce aerodynamic drag, meeting aerospace OEM standards such as NA/EU EN 9100.

- Semiconductor Wafer Lapping: Laps silicon wafers with micron-level precision (flatness within 2μm per 100mm), essential for accuracy in circuit printing and microchip fabrication.

- PCD Product Manufacturing:

- PCD Tool Finishing: Finishes PCD cutting tools used in automotive metal machining, enhancing sharpness and tool life by 50% compared to mid-tier diamonds.

- PCD Paste/Slurry: Serves as the core grit in high-end PCD paste formulations, ensuring uniform polishing of PCD wear parts like oil drilling bits and mining tools.

- Luxury Gem & Optical Glass:

- Luxury Gem Polishing: Ideal for polishing diamonds, rubies, and emeralds to the highest standards, achieving 95%+ light reflectivity, essential for high-end jewelry like engagement rings.

- Optical Glass Processing: Grinds and polishes camera lenses, laser components, and aerospace optical windows to meet stringent quality standards like EU EN 12150 and NA ANSI Z87.1.

Technical Specs

- Particle Size Range: 0–0.125~40–60μm

- Crystal Shape: Block Grain (highly concentrated size distribution)

- Bond Compatibility: Resin, Vitrified, Metal (premium), Electroplated (high-adhesion)

- Toughness: ★★★ (Triple Yellow Bars)

- Thermal Stability: Up to 850°C

- Impurity Content: ≤0.1% (Nitrogen ≤0.05%, Boron ≤0.02%)

- Hydrophilic Performance: High (90%+ dispersion in water-based slurries)

FAQ

Q1: What makes SND-M15 ideal for PCD products?

A: SND-M15’s blocky grains and ultra-low impurities provide uniform dispersion in PCD paste and slurry. It ensures PCD tools have sharper edges and 50% longer service life, crucial for industrial machining applications.

Q2: Can SND-M15 be used in automated polishing systems?

A: Yes, its hydrophilic properties and tightly controlled PSD enable excellent grit dispersion in automated polishing systems, ensuring consistent performance in aerospace, automotive, and precision glass industries.

Q3: How does SND-M15 improve luxury gem polishing?

A: The blocky crystal grains in SND-M15 ensure gentle, uniform material removal, avoiding over-polishing and achieving a higher level of light reflectivity. For diamonds, it provides up to 95% light reflectivity, enhancing the brilliance of high-end jewelry and reducing rejection rates.

Q4: What’s the shelf life and storage for SND-M15?

A: SND-M15 has a shelf life of 48 months when stored in vacuum-sealed, moisture-proof packaging. Store in a cool, dry place (18–25°C, <60% humidity) to preserve its hydrophilic properties and prevent clumping. Avoid exposure to oils or contaminants as these can affect bond adhesion.

Отзывы

Отзывов пока нет.