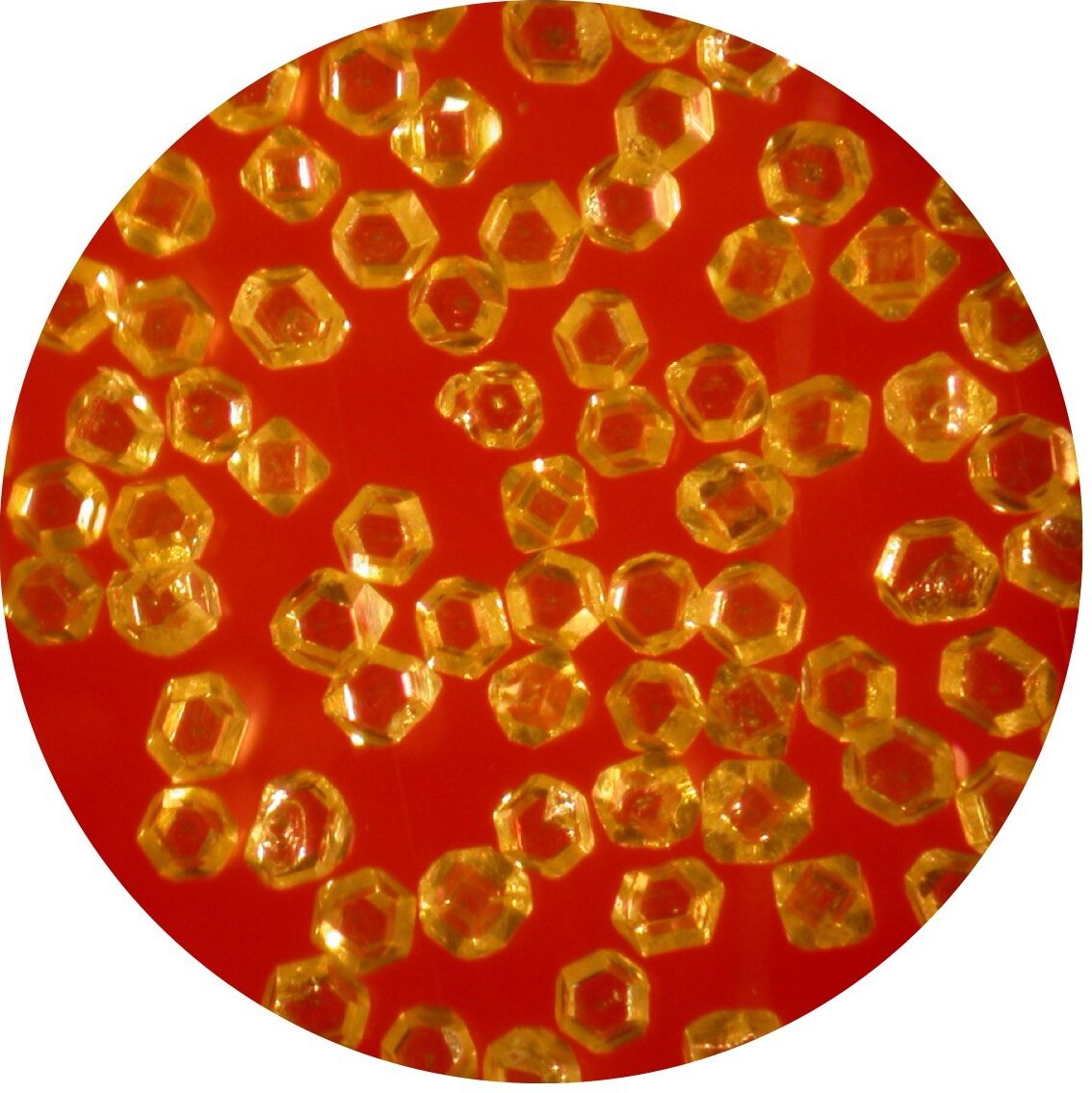

SND-G40 Fine-Size Metal Bond Synthetic Diamond Powder (Equiv. MBD8)

Description:

SND-G40 is made from ultra-pure synthetic diamond (≥99.7% carbon content), offering highly regular crystal structures with minimal inclusions and uniform edge angles. These features provide consistent performance in glass core drilling and decorative engraving, where sharpness retention, vibration resistance, and tool stability are crucial.

With medium-high toughness (Vickers hardness: 6,800–7,200 HV) and thermal stability (up to 850°C), SND-G40 ensures reliable results in tasks requiring prolonged contact with thick glass. For NA architectural glass (e.g., window panels) and EU decorative glass (e.g., wine bottles, furniture panels), this diamond powder delivers a wear rate of ≤0.5% after 40 hours of use. Unlike lower-grade diamonds, SND-G40 maintains sharpness and performance even under extended usage, making it ideal for high-precision applications.

The tight size tolerance (±6%) ensures consistent grit distribution, improving the diameter of drilled holes and ensuring uniform engraving depth. With 12–15 N impact resistance, it withstands the vibration encountered during core drilling, preventing premature tool wear.

Applications:

- Glass Core Drilling: For NA architectural glass (1/2”/12mm diameter holes) and EU decorative glass (wine bottles, furniture panels).

- Decorative Glass Engraving: For fine engraving details on glass and crystal surfaces, including wine bottles and furniture accents.

- Pencil Edging Glass: Perfect for NA/EU furniture standards, used for glass tabletops and fine edging of decorative glass.

Key Features and Benefits:

- Medium-High Toughness: Vickers hardness of 6,800–7,200 HV provides optimal balance between sharpness and durability.

- Superior Thermal Stability: Withstands temperatures up to 850°C, ideal for extended glass processing tasks like core drilling and engraving.

- Long-Lasting Sharpness: Maintains cutting sharpness during extended contact with thick glass and other materials, reducing downtime.

- High Impact Resistance: 12–15 N impact resistance allows the diamond powder to handle vibration during glass core drilling and engraving.

- Tight Size Tolerance: ±6% size tolerance ensures consistent grit distribution for better tool performance and surface finish.

Available Mesh Sizes:

- 80/100 (150–180μm) – Coarse glass core drilling

- 100/120 (125–150μm) – Deep glass engraving

- 140/170 (88–106μm) – Fine engraving details

- 270/325 (45–53μm) – Pre-polishing engraved glass

FAQ:

Q1: What’s the maximum glass thickness SND-G40 can handle?

A: SND-G40 is suitable for glass core drilling and engraving applications up to 1”/25mm thick, such as NA architectural glass (window panels) and EU furniture glass (e.g., tabletops). For glass thicker than 1.5”/38mm, we recommend using SND-G60 for higher toughness. SND-G40 is excellent for medium-load commercial glass applications.

Q2: Can SND-G40 be used for pencil edging glass tabletops?

A: Yes, SND-G40 is ideal for pencil edging glass used in furniture (e.g., 24”/600mm tabletops). Use 100/120 mesh for initial shaping and 270/325 mesh for pre-polishing the edges, resulting in a smooth edge with minimal rework—reducing production time by 18%.

Q3: How does SND-G40 compare to SND-G30 for glass applications?

A: SND-G40 offers 30% better impact resistance and 15% higher thermal stability than SND-G30, making it better suited for medium-load applications like core drilling and deep engraving. While SND-G30 is ideal for light beveling, SND-G40 is the preferred choice for tasks that involve prolonged tool contact and vibration, such as drilling 50+ glass panels per day.

Отзывы

Отзывов пока нет.