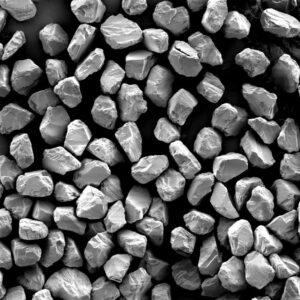

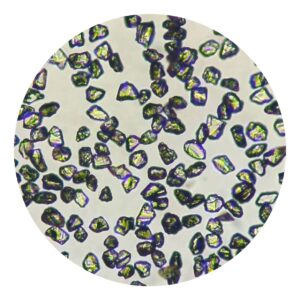

8-16 μm Diamond Micron Powder for Balanced Precision and Efficiency

SinoDiam – Industrial Diamond Micron For Consistent Quality and Repeatable Output.The 8-16 μm diamond micron range is engineered for mid-range applications where a controlled removal rate and precision balance are essential. This window provides stable, repeatable performance across various process conditions, making it the most versatile choice for industrial precision machining.</p >Common applications include metal bond wheels, resin bond wheels, precision ceramic machining, semiconductor thinning, and pre-finishing optical grinding. Both mono-crystalline and poly-crystalline grades are available to meet specific process and material requirements, ensuring consistent output over long production runs.</p >Selecting the 8-16 μm range allows manufacturers to achieve an ideal compromise between material removal and surface finish. It offers reliable process control, reduces variability, and minimizes the risk of subsurface damage. This range is often used as the standard baseline in industrial setups when precise removal targets and surface quality standards are required.</p >

Comparison Table

| Micron Range | Position | Notes |

|---|---|---|

| <6 μm | Finishing Bias | Ultra-fine, minimal removal |

| 8-16 μm | Balanced | Stable mid-range performance, repeatable output |

| >20 μm | Aggressive Removal | High removal rate, higher chipping risk |

Specification Table

| Property | Value |

|---|---|

| D50 Range | 8-16 μm |

| Shape | Mono / Poly available |

| Bond Compatibility | Metal and Resin |

| Key Advantage | Predictable processing window for stable machining |

[SinoDiam-Industrial-Diamond-Micron|8-16um|Process-Control|Balanced-Precision|Mono-Poly|Japan-Korea Alignment]https://diamondmicron.com/product/micron-diamond-powder/