OEM/ODM Manufacturer Cerium Oxide Polishing Powder - FCZ925 Per Alloyed Metal Powder Used For Granite Muti Cutting Blades – SinoDiam

OEM/ODM Manufacturer Cerium Oxide Polishing Powder - FCZ925 Per Alloyed Metal Powder Used For Granite Muti Cutting Blades – SinoDiam Detail:

FCZ925 Per Alloyed Metal Powder Used For Granite Muti Cutting Blades

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCZ925

|

Main Element | Fe, Cu, Zn |

| Theoretical Density | 8.01g/cm³ | |

| Sintering Temperature | 830℃ | |

| Bending Strength | 1200Mpa | |

| Hardness | 98-102HRB |

3. FCZ925 Pre-alloyed Powder Character

- This FCZ925 pre alloyed powder has a good wetting and holding ability to the diamond, low bulk density, easy cold forming and great sharpness.

- Applied to medium diameter granite saw blade, granite muti cutting blades, segments for graite blade.

4. Usage Instruction for Granite Muti Cutting Blade

- Metal Powder

- 50-70% FCZ925

- + 10-20% Cu

- + 1-3% Sn

- +5-10% Zn

- + Fe for balance

B. Diamond

- 35/40 @ 30%

- 40/45 @ 50%

- 45/50 @20%

- Diamond Concentration @ 30-35%

C. Sintering Temperature 790-810℃

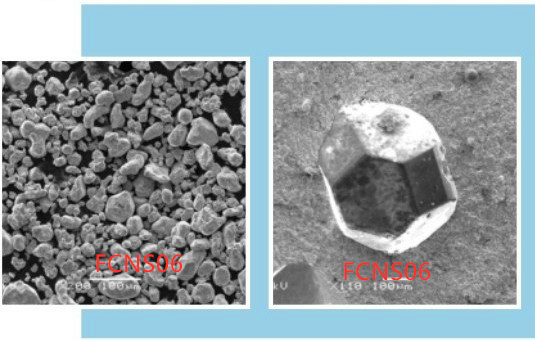

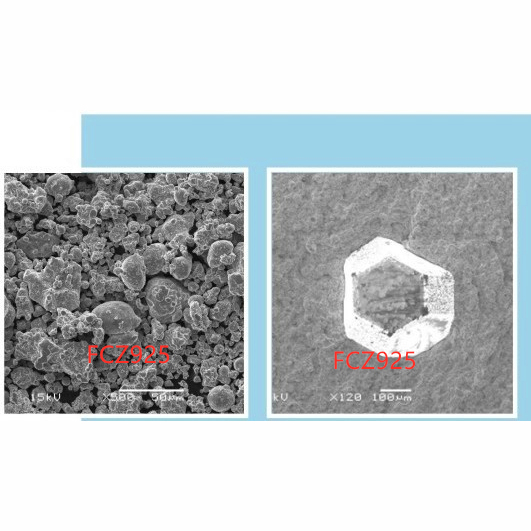

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

With our rich working experience and thoughtful companies, we have now been recognized as being a trustworthy supplier for a lot of global potential buyers for OEM/ODM Manufacturer Cerium Oxide Polishing Powder - FCZ925 Per Alloyed Metal Powder Used For Granite Muti Cutting Blades – SinoDiam , The product will supply to all over the world, such as: Guinea, Florida, Bandung, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.