OEM Factory for Sythetic Diamond Raw Material - Polycrystalline Diamond Compact PDC Cutter For Concrete and Asphalt Milling Bits – SinoDiam

OEM Factory for Sythetic Diamond Raw Material - Polycrystalline Diamond Compact PDC Cutter For Concrete and Asphalt Milling Bits – SinoDiam Detail:

PDC Cutter For Concrete and Asphalt Milling Bits

1. What is PDC- Polycrystalline Diamond Compact?

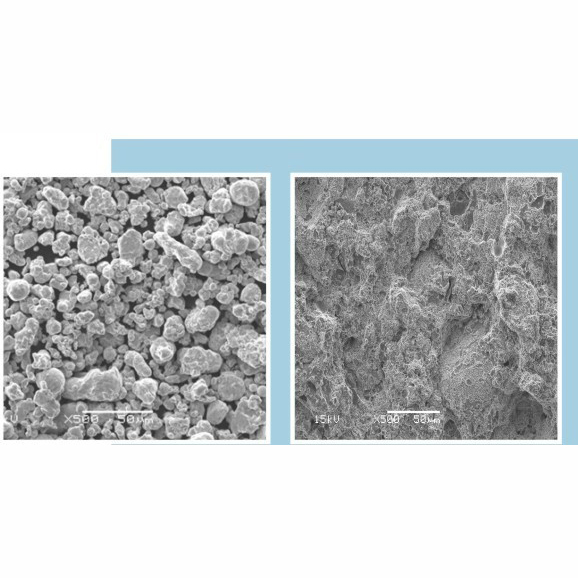

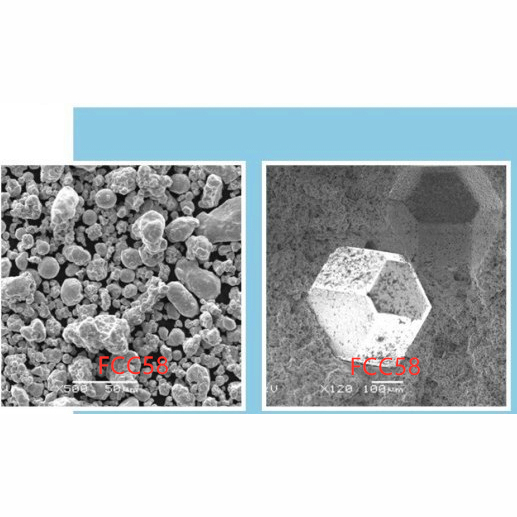

PDC- Polycrystalline diamond compact is composed of polycrystalline diamond layer and tungsten carbide substrate, the polycrystalline diamond layer possesses extremely high hardness and abrasion resistance whereas the tungsten carbide substrate would greatly improve the malleability and weld ability of the whole composite, the polycrystalline diamond compost is used oil well drilling petroleum, geology exploring, coalfield mining and mechanical industry.

PDC cutters for geological mining field drilling bits series are designed for markets in the pursuing of cost. This series PDC are mainly used for producing anchor-shank drill bits, which are equipped with sharp edge, fast footage, high effectiveness, stability, economical and practical advantages.

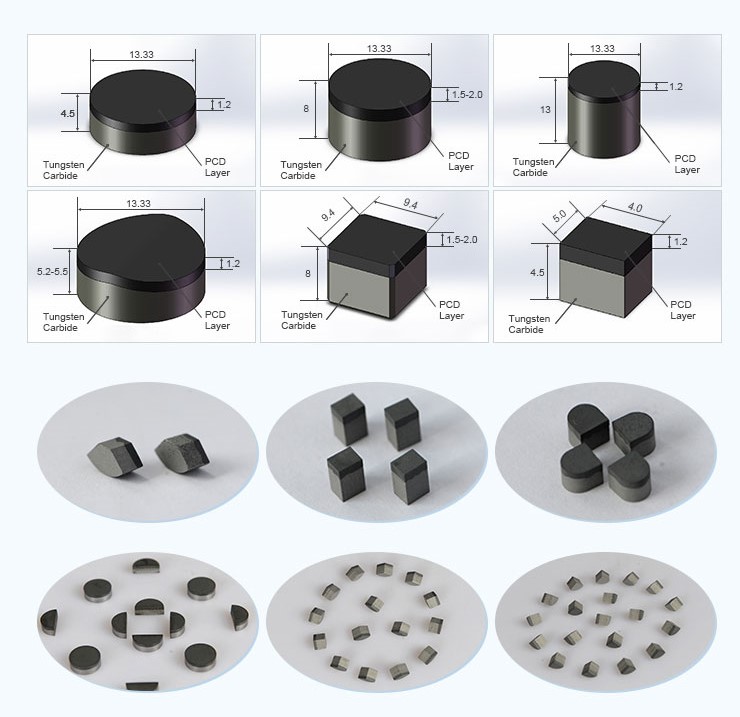

2. Specificaiton and Application of the PDC cutter

| PDC cutter for Coal Mining, Geological Exploration, Stone Processing, Road Milling | |||

| Model | 0808, 1004, 1008, 1204, 1304, 1308, 1313, 1608, 1613, 1616, 1908, 1913,1916, 1919 | 1306, 1308 | 1305, 1308 |

| Application | Making geological and coalmine drill bits for medium-hard rocks | Making geological& coalmine drill bits for soft rocks | Making geological& coalmine drill bit for hard rocks |

| Advantages | High wear resistance and impact resistance. | Faster rock breaking speed in soft rocks | Longer useful life, and High impact resistance in hard rocks |

3. Other PDC Cutter Shapes

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for OEM Factory for Sythetic Diamond Raw Material - Polycrystalline Diamond Compact PDC Cutter For Concrete and Asphalt Milling Bits – SinoDiam , The product will supply to all over the world, such as: Manchester, Milan, Canberra, We have our own registered brand and our company is developing rapidly owing to high quality products, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.