OEM Factory for Noble Marble Polishing Powder - FCP321 Pre-alloyed Powder For Medium Diameter Granite Saw Blade – SinoDiam

OEM Factory for Noble Marble Polishing Powder - FCP321 Pre-alloyed Powder For Medium Diameter Granite Saw Blade – SinoDiam Detail:

FCP321 Pre-alloyed Powder For Medium Diameter Granite Saw Blade

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCP321

|

Main Element | Fe, Cu, P |

| Theoretical Density | 7.81g/cm³ | |

| Sintering Temperature | 850℃ | |

| Bending Strength | 1600Mpa | |

| Hardness | 105-110HRB |

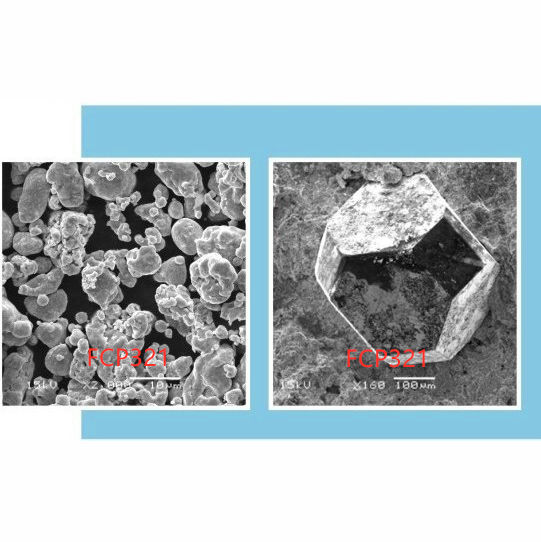

3. FCP321 Pre-alloyed Powder Character

- The Sintered Structure of the product is uniform, fine and compact, the diamond is wetted and mechanically wrapped. Low bulk density, easy cold forming and good sharpness.

- Applied to the diamond tools such as medium diameter saw blade, granite muti cutting blades, and small saw blades.

4. Usage Instruction for Medium Diamter Diamond Saw Blade

- Metal Powder

- 40-70% FCP321

- + 10-20% Cu

- + 1-3% Sn

- +5-10% Zn

- + Fe for the balance

B. Diamond

- 35/40 @ 30%

- 40/45 @ 50%

- 45/50 @20%

- Diamond Concentration @ 20-30%

C. Sintering Temperature 800-820℃

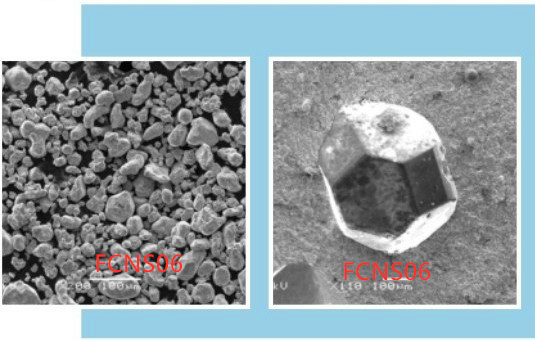

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

"Based on domestic market and expand abroad business" is our enhancement strategy for OEM Factory for Noble Marble Polishing Powder - FCP321 Pre-alloyed Powder For Medium Diameter Granite Saw Blade – SinoDiam , The product will supply to all over the world, such as: Honduras, Pretoria, Albania, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality objects we offer you, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and in depth parameters and any other info weil be sent to you timely for the inquiries. So you should make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We're confident that we are going to share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!