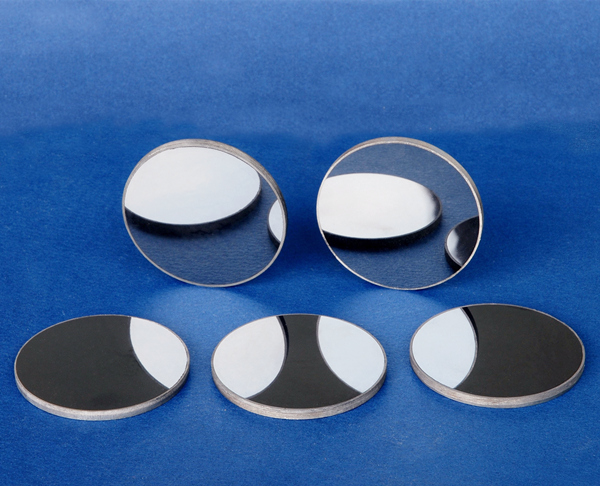

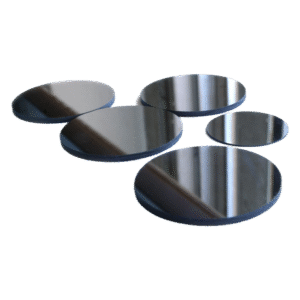

PCBN Product Range & Specifications

| Code # | Diameter (mm) | Diamond Layer (mm) | Height (mm) | Abrasive Ratio | Features | Applications |

|---|---|---|---|---|---|---|

| HC1303 | 13.5 | 0.8-1.0 | 3.2 | >10000 | High CBN content, excellent wear resistance, high chemical stability, strong weld base | Grey cast iron, powered metal, heat-resisting alloys, quench alloy, tool steel, die steel |

| HCF1304 | 13.5 | 0.8-1.0 | 4.5 | High wear resistance, superior rupture strength, robust anti-rupture properties | Chilled steel, grey cast iron, hard cast iron, iron-based powder metallurgy, machinery parts | |

| HC3201 | 32.0 | 0.8-1.0 | 1.6 | High wear resistance, excellent for fine precision cutting | Grey cast iron, heat-treated alloys, cast iron | |

| HC3202 | 32.0 | 0.8-1.0 | 2.4 | Good chemical stability, high abrasion resistance | Chilled steel, grey cast iron, high-speed steel | |

| HB0903 | 9.55 | 3.18 | 3.18 | >5000 | Pure CBN glomerocryst, no tungsten carbide base, high efficiency, both sides usable as cutting edges | Grey cast iron, cast iron, chilled steel, quench alloy, machinery parts |

| HB1204 | 12.7 | 4.76 | 4.76 | High rupture strength, precision cutting, dual-sided usage | Grey cast iron, chilled steel, quench alloy | |

| LC1303 | 13.5 | 0.8-1.0 | 3.2 | >3000-4000 | Moderate CBN content, high wear ratio, good anti-rupture strength | Chilled steel, grey cast iron, hard cast iron, sintered materials |

| LC3201 | 32.0 | 0.8-1.0 | 1.6 | Balanced wear resistance, precise machining ability | Grey cast iron, iron-based powder, metallurgical components | |

| LC3203 | 32.0 | 0.6-0.8 | 3.2 | Low CBN content, ideal for medium-duty cutting | Hard cast iron, chilled steel, cast alloys |

Key Features of Our PCBN Products:

- Superior Hardness & Wear Resistance: Ideal for high-speed cutting and abrasive applications.

- Thermal Stability: Designed to maintain performance at extreme temperatures.

- Chemical Resistance: Resistant to thermal shock, oxidation, and chemical wear.

- Dual-Sided Cutting: Many products, like HB0903 and HB1204, can be used both sides for increased efficiency and cost-effectiveness.

- High Precision: Provides consistent, reliable cutting performance for high-precision industries such as automotive, aerospace, and metalworking.

Applications of PCBN Composites:

- Precision Cutting: Hard materials such as hardened steel, grey cast iron, quench alloys, tool steel, and die steel.

- Grinding: Used in high-performance grinding for machinery, automotive parts, and aerospace components.

- Industrial Machining: Ideal for cutting and finishing tough materials that require high wear resistance and heat stability.

- Automotive & Aerospace: Precision parts manufacturing, including engine components, brake discs, and gear cutting.

Why Choose Our PCBN Products?

- Longer Tool Life: Engineered to last longer than traditional carbide tools.

- Cost-Efficient: Maximize performance while reducing downtime with dual-sided cutting tools.

- Versatile Applications: Works across a wide range of industries, including metalworking, automotive, and aerospace.

- High Efficiency: Designed to deliver consistent, high-efficiency cutting with minimal maintenance required.

| Polycrystalline Diamond (PCD) Tools for Precision Machining |

Beoordelingen

Er zijn nog geen beoordelingen.