Manufactur standard Gemstone Polishing Powder - CCS25 FeCuSn Pre-Alloyed Powder for High Quality Marble Blade – SinoDiam

Manufactur standard Gemstone Polishing Powder - CCS25 FeCuSn Pre-Alloyed Powder for High Quality Marble Blade – SinoDiam Detail:

- What is CCS25 pre-alloyed metal powder?

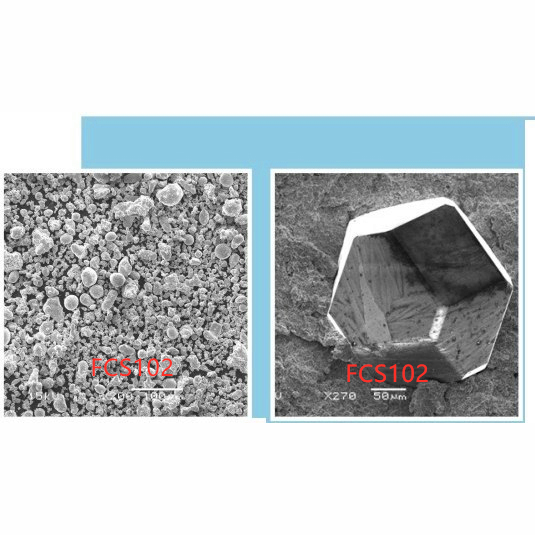

CCS25 is Cu, Co, Sn composited pre alloyed powder, which has a fine, unifor and compact sintering structure, has a great wetting and holding ability on the diamond, suitale for produce the high quality marble cutting blade.

2. The parameters of CSS25 powder

|

Main Element | Cu, Co, Sn |

| Theoretical Density | 8.29g/cm³ | |

| Sintering Temperature | 760℃ | |

| Beding Strength | 800 MPa | |

| Hardness | 85-95HRB |

3. Applicaiton Instuctions —Marking a marble saw blade

A. Metal Powder Percentage

CCS25—-50-70%

Cu——–25-35%

Sn——–4-7%

B. Diamond

50/60—-30%

60/70—-40%

70-80—-30%

C. Other

Diamond Concentration: 20-25%

Sintering Temperature: 760-780℃

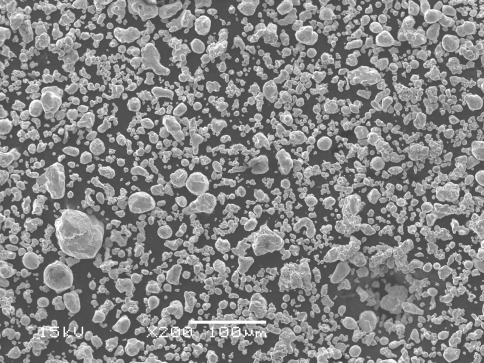

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

With our great management, potent technical capability and strict excellent handle procedure, we continue on to provide our customers with reputable top quality, reasonable selling prices and great providers. We purpose at becoming amongst your most trusted partners and earning your satisfaction for Manufactur standard Gemstone Polishing Powder - CCS25 FeCuSn Pre-Alloyed Powder for High Quality Marble Blade – SinoDiam , The product will supply to all over the world, such as: Serbia, Montpellier, Washington, We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

Write your message here and send it to us