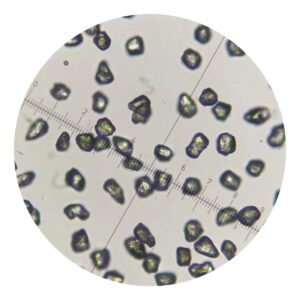

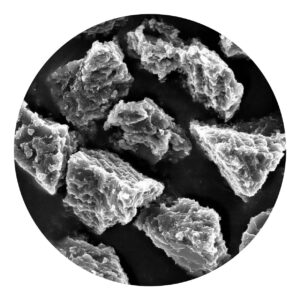

3-6 μm Diamond Micron Powder for Ultra-Fine Finishing

SinoDiam – Industrial Diamond Micron For Consistent Quality and Repeatable Output.The 3-6 μm diamond micron range represents the ultra-fine spectrum designed for precision finishing applications where controlled material removal and minimal subsurface damage are critical. This size window offers stable performance under high process repeatability requirements, making it ideal for sensitive applications that demand consistent surface integrity.</p >Typical applications include optical glass superfinishing, semiconductor packaging pre-polish, ceramic high-precision finishing, and sapphire ultra-fine lapping. Both mono-crystalline and poly-crystalline options are available to match specific process requirements and material characteristics.</p >Choosing the 3-6 μm window ensures an optimal balance between removal rate and surface quality. It provides sufficient cutting action to advance the finishing process while maintaining minimal risk of micro-cracking or surface defects. Compared to sub-3 μm grades, it significantly improves throughput without compromising the ultra-precision finish.</p >

Comparison Table

| Micron Range | Removal Rate | Subsurface Damage Risk | Best Use Case |

|---|---|---|---|

| 1-3 μm | Low | Lowest | Cosmetic finishing |

| 3-6 μm | Medium-Low | Very Low | Ultra-fine finishing |

| 6-10 μm | Medium | Medium | Fine grinding |

Specification Table

| Property | Value |

|---|---|

| D50 Range | 3-6 μm |

| Shape | Mono / Poly available |

| Surface Treatment | Hydrophilic / Hydrophobic customizable |

| Key Advantage | High stability narrow size distribution suitable for repeatable processing |

[SinoDiam-Industrial-Diamond-Micron|3-6um|Process-Control|Precision-Finishing|Mono-Poly|Japan-Korea Alignment]https://diamondmicron.com/product/micron-diamond-powder/