SinoDiam Materials & Technologies introduces the SND210 Oil-Soluble Diamond Compound, a high-performance diamond polishing paste engineered for precision lapping, polishing, and finishing of carbide drawing dies, cold heading dies, molds, and precision tools.

Formulated with premium synthetic diamond or cubic boron nitride (CBN) micro-particles and a stable oil-based carrier, this compound delivers uniform material removal, consistent surface finish, and superior process control—ideal for professional toolmaking, mold repair, and fine surface finishing applications.

🌟 Key Features & Benefits

- High Precision Polishing – Ensures mirror-like surface quality on tungsten carbide, hardened steel, ceramics, and mold materials.

- Uniform Diamond Dispersion – Stable formulation guarantees even diamond distribution for predictable, repeatable performance.

- Versatile Performance – Suitable for manual lapping, ultrasonic polishing, and machine finishing processes.

- Oil-Soluble Formula – Excellent lubrication, long working time, and compatibility with most metal surfaces.

- Customizable Options – Choose diamond type, size, and concentration to match your application.

🔧 Product Overview

| Category | Details |

|---|---|

| Application | Precision lapping and polishing of carbide drawing dies, cold heading dies, injection molds, and tool steel. |

| Composition | Synthetic diamond or CBN blended with high-viscosity oil-based lubricants and stabilizers for smooth, consistent performance. |

| Form | Oil-soluble diamond paste compound (ready to use). |

🧩 4-Step Customization Guide

1️⃣ Choose Diamond or CBN Type

Select the abrasive crystal structure that fits your polishing goal:

- SJK-5 (Monocrystal Diamond) – The most widely used diamond for polishing compounds, offering excellent cutting performance and consistent finish.

- Poly (Polycrystalline Diamond) – Features multi-crystal structure for high stock removal rate and effective polishing of hard, wear-resistant materials.

- SinoDiam+ (Surface-Enhanced Diamond) – Modified crystal surface for superior cutting speed, smoother finish, and longer service life.

- Cubic Boron Nitride (CBN) – The best choice for ferrous materials, providing hardness comparable to diamond with chemical stability on steel.

2️⃣ Choose Diamond Size (Micron & Mesh Equivalent)

| Diamond Size (μm) | Mesh | Recommended Use |

|---|---|---|

| W0.25 – W1 | #60,000–14,000 | Super mirror polishing (optical molds, dies, ceramics) |

| W3 – W9 | #8,000–1,800 | Fine polishing, bright finish |

| W13 – W17.5 | #1,500–1,000 | General polishing, brightness |

| W25 – W50 | #800–400 | Coarse grinding, lapping, and surface correction |

3️⃣ Choose Concentration

- Light – Ideal for final mirror finishing and inspection-grade surfaces.

- Medium – Balanced compound for both material removal and finishing.

- Heavy – Designed for aggressive cutting and pre-polishing stages.

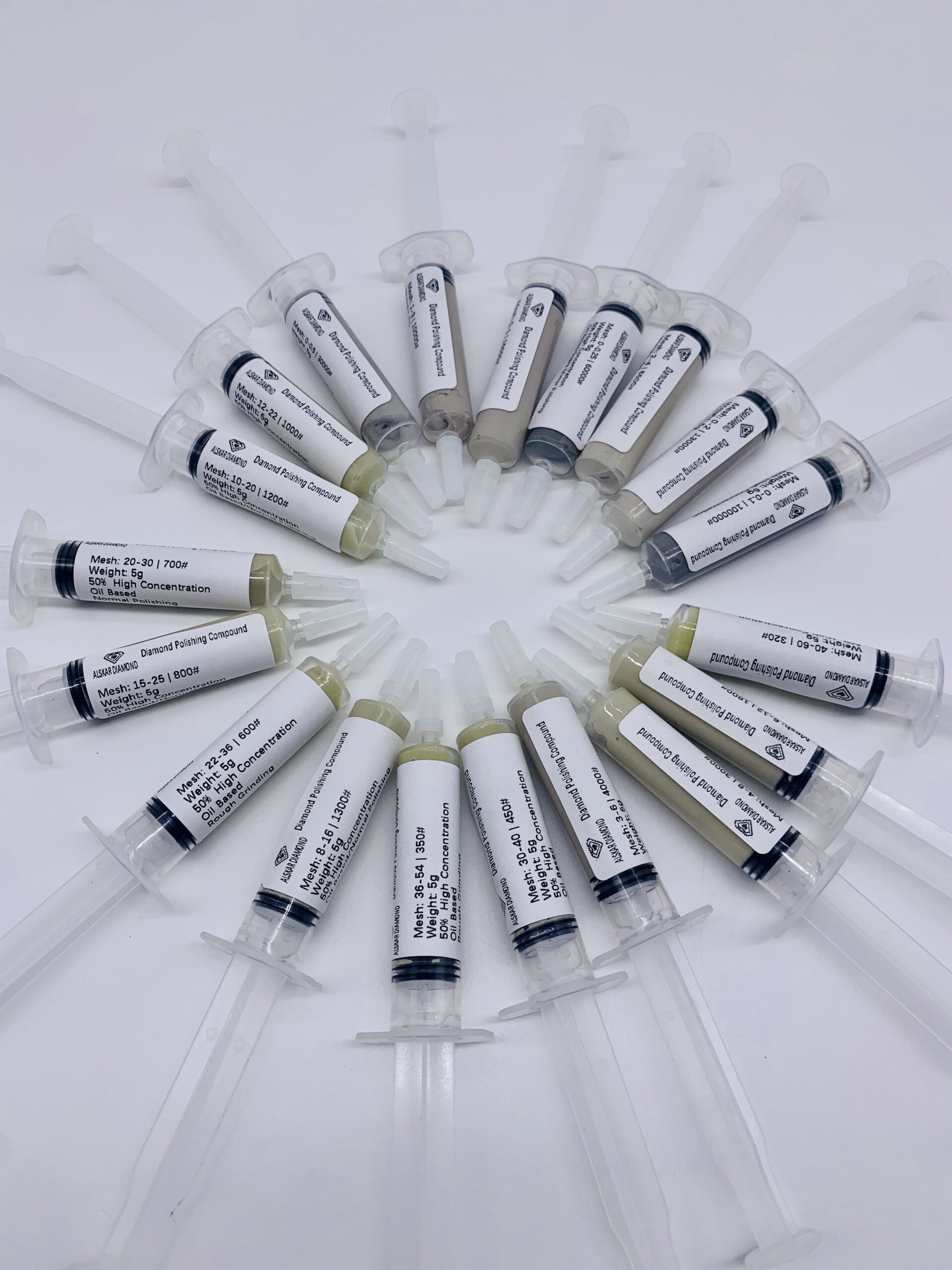

4️⃣ Choose Packaging

Flexible packaging designed for both lab and industrial use:

- Tubes: 5g / 10g / 18g / 25g / 50g

- Jars: 5g / 25g / 50g / 100g / 200g

💎 Why Choose SinoDiam SND210?

- Precision Engineered – Consistent performance with tightly controlled diamond particle distribution.

- High Lubricity Carrier – Oil-based formulation minimizes friction and extends tool life.

- Application Versatility – Perfect for carbide die finishing, mold polishing, tool refurbishment, and mirror finishing.

- Custom Formulations Available – Options for diamond/CBN type, particle size, and concentration tailored to your production process.

💬 Top 10 FAQs about SND210 Oil-Soluble Diamond Compound

1. What is the SinoDiam SND210 Oil-Soluble Diamond Compound used for?

The SND210 is a diamond lapping and polishing compound designed for mold, die, and carbide polishing applications. It’s ideal for achieving mirror finishes and fine surface correction on materials like tungsten carbide, tool steel, and ceramics.

2. What makes the SND210 different from water-soluble diamond paste?

SND210 uses an oil-based carrier, providing superior lubrication, longer working time, and reduced drying—perfect for polishing metal and carbide dies.

Water-soluble compounds (like SND700) are preferred when cleaning convenience or non-oily residues are required, such as in research or cleanroom environments.

3. Can I use the SND210 for polishing ferrous materials like steel?

Yes, but for ferrous materials, CBN (Cubic Boron Nitride) compound options are recommended instead of diamond, as CBN offers chemical stability with iron-based alloys, preventing unwanted reactions or scratches.

4. What diamond sizes are available in SND210?

SND210 is offered in 15 standard sizes from 0.25μm to 50μm, covering polishing stages from super mirror finishing (0.25–1μm) to coarse lapping and pre-polishing (25–50μm).

5. How do I choose the right diamond concentration?

- Light: For final finishing and mirror polishing.

- Medium: For balanced material removal and surface quality.

- Heavy: For aggressive stock removal or initial lapping.

Your choice depends on the polishing stage and surface roughness target.

6. What materials can SND210 polish?

It effectively polishes tungsten carbide, hardened tool steel, ceramics, glass, silicon, and mold inserts—common materials in precision toolmaking, semiconductor molds, and die manufacturing.

7. Is the SND210 suitable for both manual and machine polishing?

Absolutely. It performs equally well in manual polishing with felt or cloth pads, rotary hand tools, and automatic polishing or ultrasonic systems. The uniform oil carrier ensures consistent performance across methods.

8. What are the available packaging sizes for SND210?

SinoDiam offers tubes (5g–50g) and jars (5g–200g), supporting both R&D-scale use and industrial production environments. Custom packaging and OEM labeling are also available upon request.

9. How should the compound be stored and handled?

Store in a cool, dry place, away from direct sunlight. Keep the container tightly closed to prevent contamination. For best performance, use within 12 months of opening.

10. How can I purchase or request a quotation for SND210?

You can contact SinoDiam directly via our website www.diamondmicron.com or email our sales team for technical support, quotation, or OEM customization.

SinoDiam Water Soluble Diamond Compound Paste – Premium Petroleum-Free Lab Polishing

レビュー

レビューはまだありません。