SND-M/PCD Professional Synthetic Micron Diamond Powder: Superabrasive for PCD/PDC Production & Premium Bond Tools

Description

SND-M/PCD is developed to meet the strictest quality and purity requirements of PCD and PDC tool manufacturing, where even trace impurities can compromise tool strength and wear resistance. With total impurities ≤0.05% and Si ≤0.01%, this diamond eliminates voids and weak points in PCD compacts, resulting in dense, defect-free diamond layers during sintering.

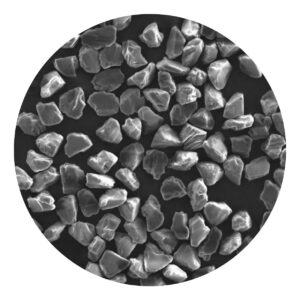

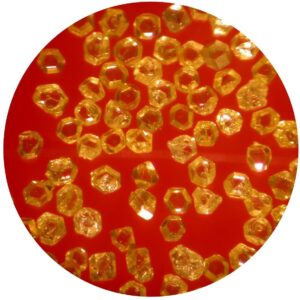

Each particle features a high-strength blocky crystal morphology, ensuring uniform bonding with cobalt (Co) and other metal binders under 1,400°C and 5–6 GPa—the extreme HPHT conditions typical of PCD sintering. The result is PCD/PDC tools with 25% higher wear resistance, 30% longer drilling life, and stable cutting performance across challenging environments like automotive aluminum machining or deep oil well drilling.

Technical Edge & Engineering

- Ultra-Low Impurity System: Purified through a 3-stage refinement process (acid leaching → vacuum heat treatment → magnetic separation) to reduce total impurities ≤0.05% and Si ≤0.01%, effectively eliminating cobalt silicide formation during sintering.

- Extreme Thermal Stability: Pre-sintering conditioning guarantees resistance to 1,400°C HPHT sintering, preventing crystal graphitization and ensuring uniform diamond grain bonding with a final PCD density ≥3.45 g/cm³.

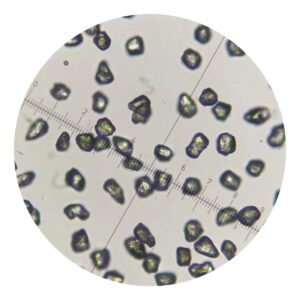

- Optimized PSD Control: Particle size distribution tightly focused within 1–10μm (fine PCD) or 10–20μm (heavy-duty PDC), with variance ≤5%, achieving uniform grain dispersion and superior compact density.

- High Structural Integrity: Blocky crystals maintain toughness under multi-directional compression, ensuring consistent PCD/PDC layer strength and preventing delamination during tool use.

Key Advantages

- Enhanced PCD/PDC Tool Life: Tools produced with SND-M/PCD deliver 25% longer cutting life and 30% higher drilling performance, reducing downtime and cost per operation.

- Superior Purity & Bonding: Ultra-low silicon prevents Co–Si reactions, resulting in defect-free PCD compacts and higher bonding strength with Co or Ni binders.

- Versatile Bond Compatibility: Perfect for metal bond wheels, vitrified bond grinding tools, and electroplated edge trimmers, minimizing inventory complexity for tool manufacturers.

- High Thermal & Pressure Endurance: Maintains integrity up to 1,400°C and 6 GPa, ensuring reliability under the most demanding HPHT PCD sintering conditions.

- Optimized for Industrial Productivity: Reduces rework and defect rates to ≤1% (vs. 5% with generic diamonds), increasing throughput and production yield for large-scale PCD/PDC facilities.

Core Applications Across Industries

1. PCD & PDC Manufacturing

- PCD Cutting Inserts: Used for producing automotive-grade PCD inserts for high-speed aluminum machining (NA: Detroit auto plants; EU: German precision machining).

- PDC Drill Bits: Enables high-strength PDC cutters for oil and gas exploration, ensuring long-lasting performance in abrasive geological formations such as granite, shale, and basalt.

2. Premium Bond Tools

- Metal Bond Grinding Wheels: For PCD tool re-sharpening and precision lapping, achieving surface roughness Ra ≤0.05μm.

- Electroplated Edge Trimmers: Used for polishing and trimming PCD wear components (e.g., injection mold inserts, wear-resistant dies) without microcracking.

- Vitrified Bond Grinding Wheels: Ideal for fine grinding of tungsten carbide and PCD composites in high-speed production lines.

Technical Specs

| Property | Specification |

|---|---|

| Particle Size Range | 1–10μm (fine PCD) / 10–20μm (PDC or heavy-duty) |

| Crystal Shape | Blocky, high-strength structure |

| Total Impurities | ≤0.05% (Si ≤0.01%) |

| PSD Concentration | Variance ≤5% |

| Bond Compatibility | Metal (premium), vitrified, electroplated |

| Thermal Stability | Up to 1,400°C |

| PCD Compact Density | ≥3.45 g/cm³ (with Co binder) |

FAQ

Q1: Why is low silicon (Si) content essential in SND-M/PCD?

A: Silicon reacts with cobalt binders to form brittle Co–Si compounds, weakening the PCD structure. With Si ≤0.01%, SND-M/PCD prevents void formation and guarantees dense, high-hardness PCD compacts.

Q2: Can SND-M/PCD be used for PDC cutters in hard rock drilling?

A: Yes—its high-strength blocky crystals and 1,400°C thermal endurance make it ideal for HPHT sintering of PDC cutters used in hard and abrasive formations like granite, sandstone, and basalt.

Q3: What particle size range is best for fine-grain PCD tools?

A: The 1–10μm range is recommended for precision cutting inserts (grain size 3–5μm), delivering razor-sharp edges and smooth cutting in aluminum, copper, and composite materials.

Q4: How should SND-M/PCD be stored to maintain purity?

A: Store in vacuum-sealed, anti-static packaging at 18–22°C, <55% humidity. Keep away from dust and chemical vapors to avoid contamination that could affect PCD compact density or bonding strength.

SND-MAG Diamond Agglomerated Micron Powder

Recensioni

Ancora non ci sono recensioni.