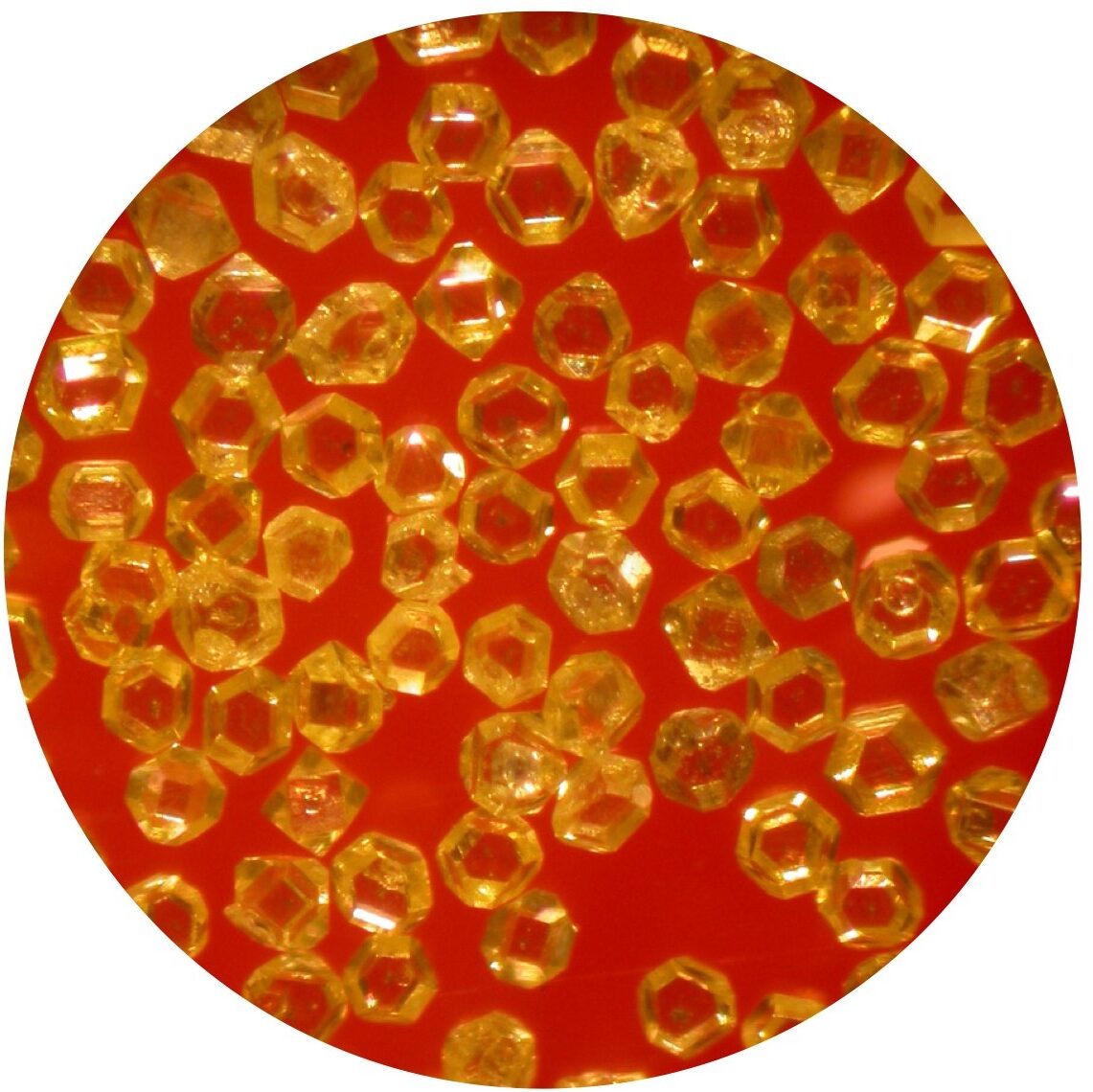

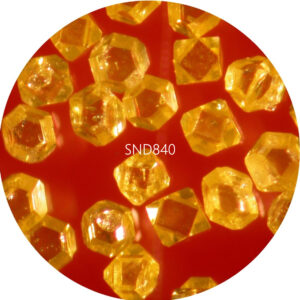

SND-G30 Fine-Size Metal Bond Synthetic Diamond Powder (Equiv. MBD6)

Description:

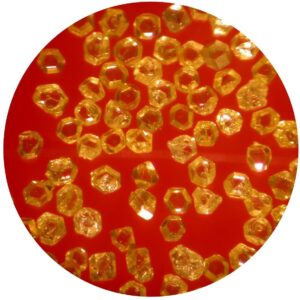

SND-G30 is crafted from high-purity synthetic diamond (≥99.6% carbon content) with an enhanced regular crystal structure. About 75–80% of the crystals have uniform edges and minimal defects, ensuring consistent and smooth material removal. Its medium toughness (Vickers hardness: 6,500–6,800 HV) and thermal stability (up to 800°C) make it the perfect choice for precision glass beveling and carbide grinding, where both surface finish and tool stability are critical.

Optimized for glass processing and carbide tools, SND-G30 delivers a Ra ≤2.0μm surface finish on NA 3/8”/10mm shower door glass and EU CNC carbide bits, outperforming generic MBD6 equivalents by 25% in reducing post-grinding rework. The tight size tolerance (±7%) ensures even grit distribution in metal bond tools, while the medium toughness strikes the right balance between sharpness and durability. It resists grit fracturing during carbide grinding (up to 10 N impact) and avoids overheating during prolonged glass beveling tasks.

Available in multiple mesh sizes, SND-G30 covers a wide range of precision grinding applications, from coarse glass shaping to fine carbide polishing, making it a versatile option for NA/EU precision manufacturing workflows.

Applications:

- Glass Beveling: Use 120/140–200/230 mesh for beveling NA shower door glass and EU furniture glass.

- Carbide Grinding: Use 200/230–325/400 mesh for EU CNC carbide bits and NA cutting tools.

- Precision Grinding: Ideal for high-precision polishing and lapping of carbide and ceramics.

Key Features and Benefits:

- Medium Toughness: Provides a balanced combination of cutting sharpness and tool durability.

- Regular Crystal Shape: 75–80% uniform crystals ensure consistent grinding performance and smooth finishes.

- High Thermal Stability: Withstands 800°C temperatures, ideal for both glass beveling and carbide grinding applications.

- Improved Surface Finish: Achieves Ra ≤2.0μm surface finish for high-quality glass polishing and precision carbide grinding.

- Cost-Effective Performance: 25% improvement over generic MBD6 powders, reducing post-grinding rework.

- Tight Size Tolerance: ±7% size tolerance for uniform metal bond tool integration and grit distribution.

Available Mesh Sizes:

- 80/100 (150–180μm) [coarse glass shaping]

- 120/140 (106–125μm) [glass beveling]

- 200/230 (63–75μm) [carbide pre-grinding]

- 325/400 (38–45μm) [fine carbide polishing]

FAQ:

Q1: Can SND-G30 be used for both glass and carbide?

A: Yes, SND-G30 is versatile and designed to handle both glass beveling and carbide grinding. For glass applications, use the 120/140–200/230 mesh range; for carbide, use the 200/230–325/400 mesh range. It offers consistent performance across both materials without the need for tool reconfiguration.

Q2: How does SND-G30 ensure a smooth glass finish?

A: SND-G30 features 75–80% uniform crystals that minimize micro-chipping during glass processing. Its medium toughness ensures consistent cutting performance, resulting in a Ra ≤2.0μm finish, meeting NA/EU standards for visible glass surfaces like shower doors.

Q3: Is SND-G30 compliant with EU glassworking standards?

A: Yes, SND-G30 complies with EU EN 13230 (safety standards for glass processing tools) and is REACH-compliant (free from restricted substances). It’s compatible with EU CE-marked metal bond tools, making it ideal for European glass manufacturers and carbide shops.

Recensioni

Ancora non ci sono recensioni.