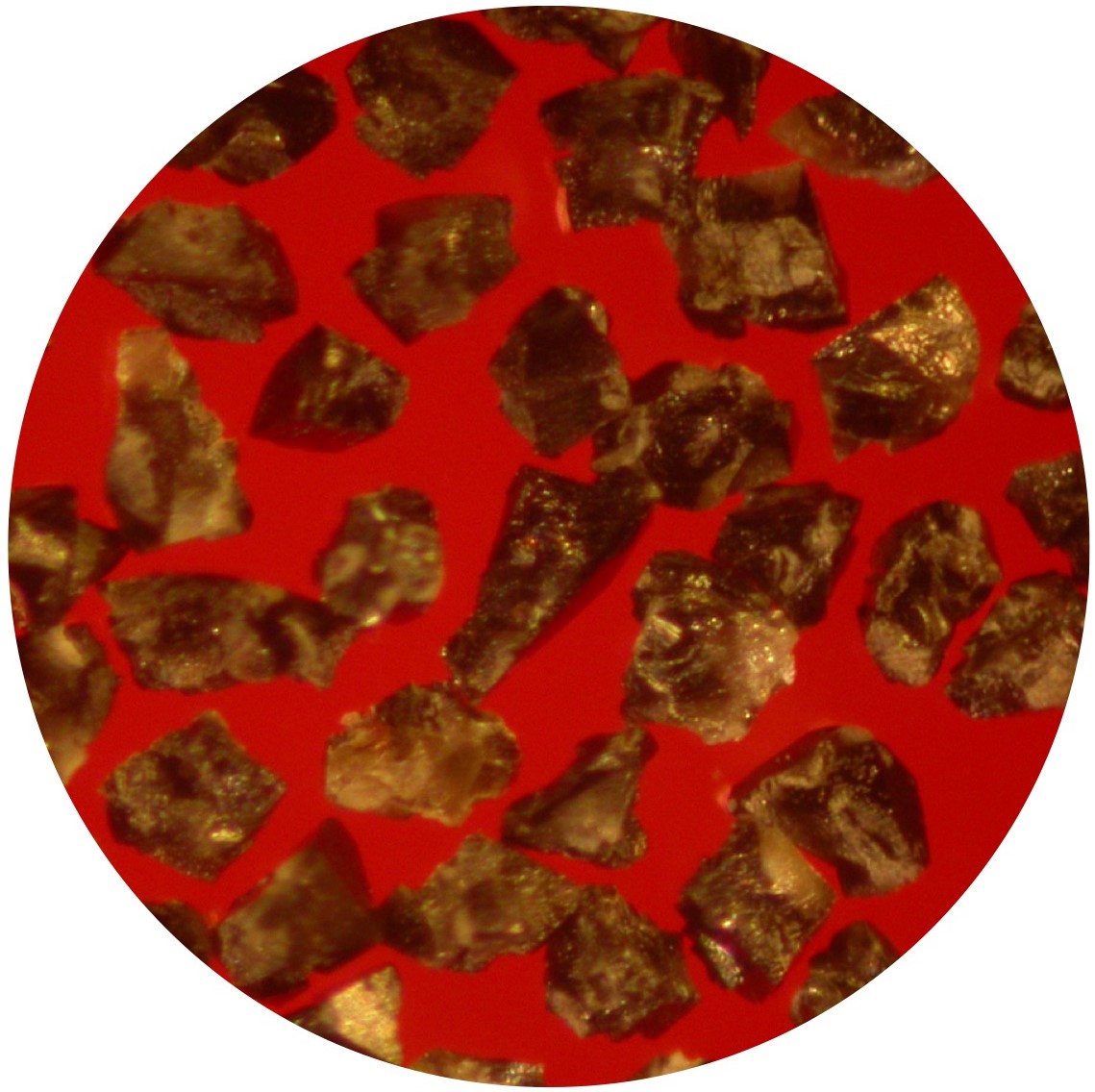

CBN-B10 Black Friable CBN – High-Efficiency Resin Bond CBN for Fine Ferrous Metal Grinding

Product Description

CBN-B10 is characterized by its deep black appearance and friable (easily fractured) structure, which allows controlled micro-fracturing during grinding. As each crystal breaks down, fresh, sharp cutting edges are exposed—enabling continuous material removal and scratch-free polishing of ferrous components.

Its low toughness is intentionally designed for fine surface finishing applications, especially in tool steel, carbon steel, and alloy steel. In resin bond matrices, CBN-B10 demonstrates excellent adhesion, ensuring grit stability while allowing the resin to release worn particles effectively—reducing surface burns and maintaining consistent grinding efficiency over long cycles.

Compared with conventional CBN abrasives, CBN-B10 delivers up to 10% smoother finishes and 18% lower tool wear, making it a cost-effective solution for precision grinding and polishing of high-hardness ferrous parts.

Core Advantages

- 🎯 Fine Grinding Precision: Friable structure enables mirror-like finishes (Ra ≤0.8 μm) on ferrous materials—ideal for precision tooling and engine components.

- 🔗 Resin Bond Optimization: Low-toughness, irregular particles bond securely with resin while maintaining sharpness, reducing grit pull-out and wheel dressing frequency.

- 💰 Cost-Effective Performance: Achieves premium-level finishes without high cost—ideal for mid-tier precision tools and automotive finishing applications.

- 🧩 Controlled Micro-Fracturing: Maintains cutting ability during prolonged fine grinding, improving both surface integrity and grinding stability.

- ⚙️ Wide Mesh Range: Available from 50/60–325/400 mesh to support various levels of finishing—from medium to ultra-fine polishing.

Technical Specifications

| Item | Details |

|---|---|

| Code No. | CBN-B10 |

| Color | Black |

| Crystal Shape | Irregular (Friable) |

| Toughness | Low |

| Available Mesh Sizes | 50/60–325/400 mesh |

| Bond Compatibility | Resin bond |

| Target Materials | Ferrous metals, Tool steel, Carbon steel, Alloy steel |

| Surface Finish (Ra) | ≤ 0.8 μm |

| Tool Wear Reduction | Up to 18% |

| Recommended Application Pressure | Low-to-medium pressure grinding |

FAQ

Q1: What does “friable” mean and why is it important for CBN-B10?

A: “Friable” means the CBN particles fracture easily under pressure, continuously exposing new sharp edges. This property is crucial for fine grinding and polishing, ensuring a smooth, scratch-free finish on ferrous materials.

Q2: Can CBN-B10 be used for rough or heavy grinding?

A: It’s designed primarily for fine or precision grinding (e.g., 120/140 to 325/400 mesh). For rough or heavy-duty grinding, choose higher-toughness grades like CBN-A10 or CBN-A20 to prevent excessive particle breakdown.

Q3: Which industries benefit most from CBN-B10?

A: Industries requiring ultra-smooth surface finishes—including automotive (engine and gearbox components), tool manufacturing (tool steel finishing), and aerospace (precision ferrous components)—rely on CBN-B10 for stable, fine grinding performance.

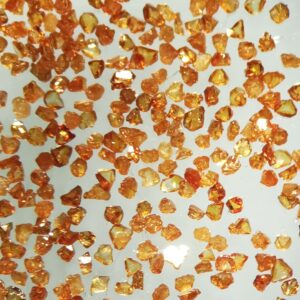

CBN-A10 Amber Irregular CBN (50/60–325/400 Mesh) – Resin Bond CBN for Ferrous Metal Grinding

CBN-B20 Bright Black Blocky CBN – High-Temp / High-Speed Grinding Expert

Ulasan

Belum ada ulasan.