Hot-selling Diamond Polishing Powder - FCCS07 FeCuCoSn Pre Alloyed Metal Powde for Medium to High Quality Diamond Tools – SinoDiam

Hot-selling Diamond Polishing Powder - FCCS07 FeCuCoSn Pre Alloyed Metal Powde for Medium to High Quality Diamond Tools – SinoDiam Detail:

FCCS07 FeCuCoSn Pre Alloyed Metal Powde for Medium to High Quality Diamond Tools

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCCS07

|

Main Element | Fe, Cu, Co, Sn |

| Theoretical Density | 7.84g/cm³ | |

| Sintering Temperature | 790℃ | |

| Bending Strength | 1500Mpa | |

| Hardness | 105-110HRB |

3. FCCS07 Pre-alloyed Powder Character

- The powder has good wetting ability to the diamond and great mechanical granulating to other metal powders, it can help the products achieve a great value on speed and life.

- Applied to medium to high quality granite diamond blade, ceramic diamond blade, diamond wire and diamond core bits

4. Usage Instruction for Ceramic Cutting Blade

- Metal Powder

- 30-50% FCCS07

- + 25-35% Cu

- + 3-6% Sn

- +2-5% Ni

- +7-10% CUCS

- + Fe for the balance

B. Diamond for Dry Cutting Ceramic

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @30%

- Diamond Concentration @ 13-15%

C. Diamond for Wet Cutting Ceramic

- 50/60 @ 60%

- 60/70 @ 40%

- Diamond Concentration @ 10-12%

D. Sintering Temperature 830-850℃

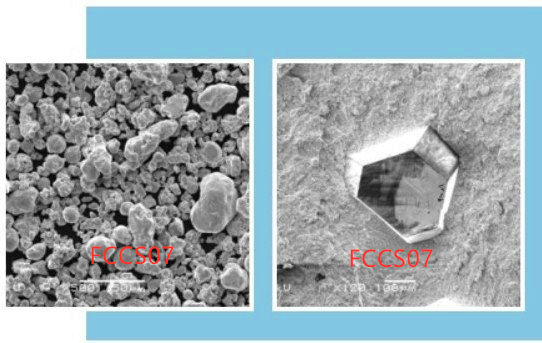

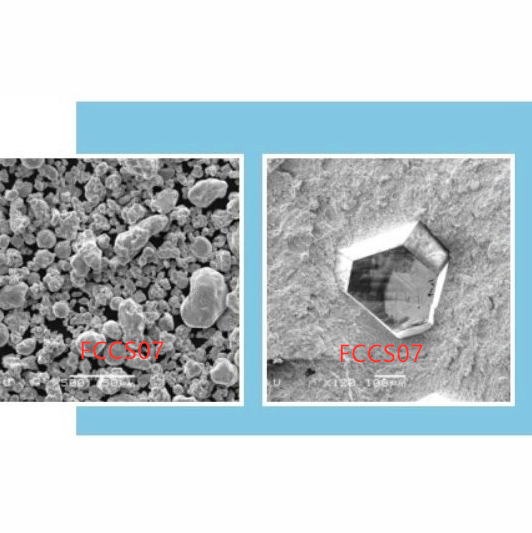

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

Generally customer-oriented, and it's our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for Hot-selling Diamond Polishing Powder - FCCS07 FeCuCoSn Pre Alloyed Metal Powde for Medium to High Quality Diamond Tools – SinoDiam , The product will supply to all over the world, such as: Slovakia, Cologne, azerbaijan, We are sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.