Hot New Products Diamond Micron Powder - FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel – SinoDiam

Hot New Products Diamond Micron Powder - FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel – SinoDiam Detail:

FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCNS06

|

Main Element | Fe, Cu, Ni, Sn |

| Theoretical Density | 8.05g/cm³ | |

| Sintering Temperature | 810℃ | |

| Bending Strength | 1100Mpa | |

| Hardness | 105-110HRB |

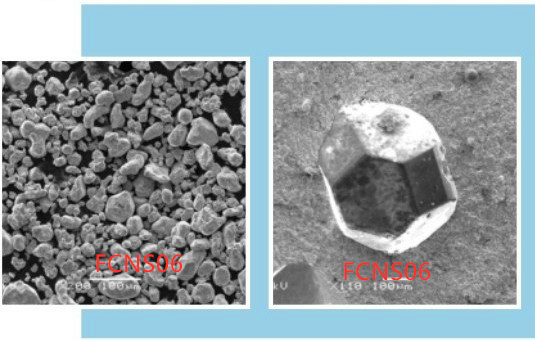

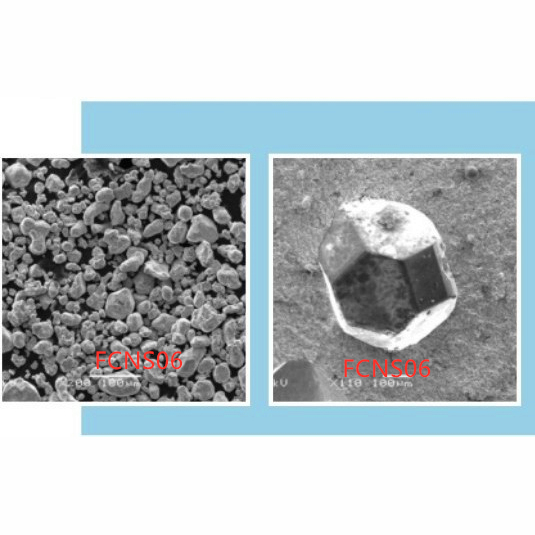

3. FCNS06 Character

- The Sintered structure of the product is uniform, fine and compact, it has good wetting and holding powder to the diamond, high hardness of the carcass, excellent wear resistance and good comprehensive performance of tools.

- The powder is applied to high quality small diameter diamond saw blade, ceramic cutting blades, ceramic gridning squaring wheel and scrapers.

4. Instructions for Making Ceramic Squaring Wheels.

- Metal Percentage:

- (40+60)% FCNS06

- + (15-25)% Cu

- + (6-10)% Sn

- + (2-5)% Ni

- + (8-12)% 663

- + Fe for Blance

B. Diamond Grit Size and Percentage:

- 70/80 @ 60%

- 80/100 @ 40%

- Concentration: (18-22)%

C. Sintering Temperature: 750-770℃

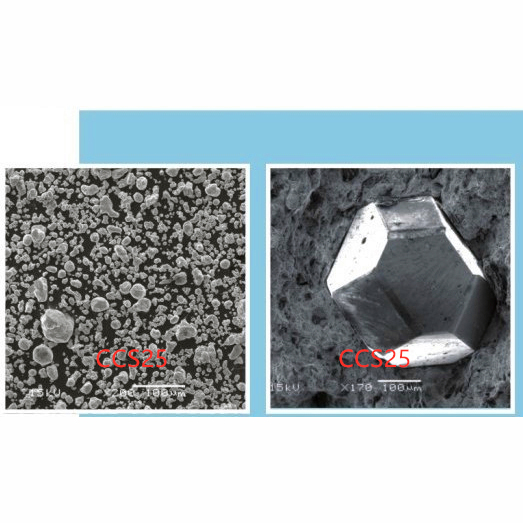

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for Hot New Products Diamond Micron Powder - FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel – SinoDiam , The product will supply to all over the world, such as: luzern, Seattle, America, With a fully integrated operation system, our company has won a good fame for our high quality products, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!