High Quality for Granite Polishing Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam

High Quality for Granite Polishing Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam Detail:

FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCNS03

|

Main Element | Fe, Cu, Ni, Sn |

| Theoretical Density | 7.98g/cm³ | |

| Sintering Temperature | 830℃ | |

| Bending Strength | 1150Mpa | |

| Hardness | 104-108HRB |

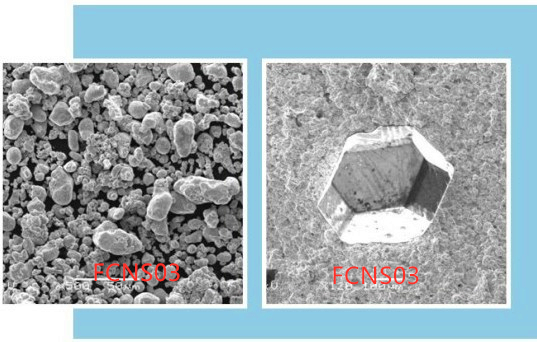

3. FCNS03 Character

- The Sintered structure is uniform and compact. the carcass has good control of diamond, great wear resistance and sharpness.

- The powder is applied to medium to high quality granite diamond blade, ceramic cutting blades.

4. Instructions for Making Ceramic Cutting Blade.

- Metal Percentage:

- (30-50)% FCNS03

- + (25-35)% Cu

- + (5-8)% Sn

- + (2-4)% Ni

- + Fe for Blance

B. Diamond Grit Size and Percentage:

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @ 30%

- Concentration: (9-12)%

C. Sintering Temperature: 840-860℃

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

We've our have sales staff, style and design staff, technical crew, QC team and package workforce. We've strict excellent control procedures for each system. Also, all of our workers are experienced in printing field for High Quality for Granite Polishing Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam , The product will supply to all over the world, such as: Thailand, Amman, Armenia, We integrate design, manufacture and export together with more than 100 skillful workers, strict quality controlling system and experienced technology.We keep long term business relationships with wholesaler and distributors form more than 50 countries, such as USA, UK, Canada, Europe and Africa etc.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.