High Quality for Granite Polishing Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam

High Quality for Granite Polishing Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam Detail:

FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCNS03

|

Main Element | Fe, Cu, Ni, Sn |

| Theoretical Density | 7.98g/cm³ | |

| Sintering Temperature | 830℃ | |

| Bending Strength | 1150Mpa | |

| Hardness | 104-108HRB |

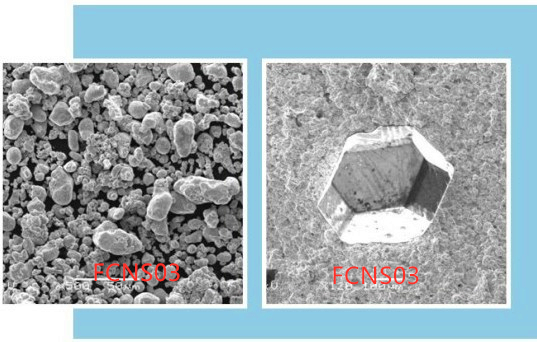

3. FCNS03 Character

- The Sintered structure is uniform and compact. the carcass has good control of diamond, great wear resistance and sharpness.

- The powder is applied to medium to high quality granite diamond blade, ceramic cutting blades.

4. Instructions for Making Ceramic Cutting Blade.

- Metal Percentage:

- (30-50)% FCNS03

- + (25-35)% Cu

- + (5-8)% Sn

- + (2-4)% Ni

- + Fe for Blance

B. Diamond Grit Size and Percentage:

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @ 30%

- Concentration: (9-12)%

C. Sintering Temperature: 840-860℃

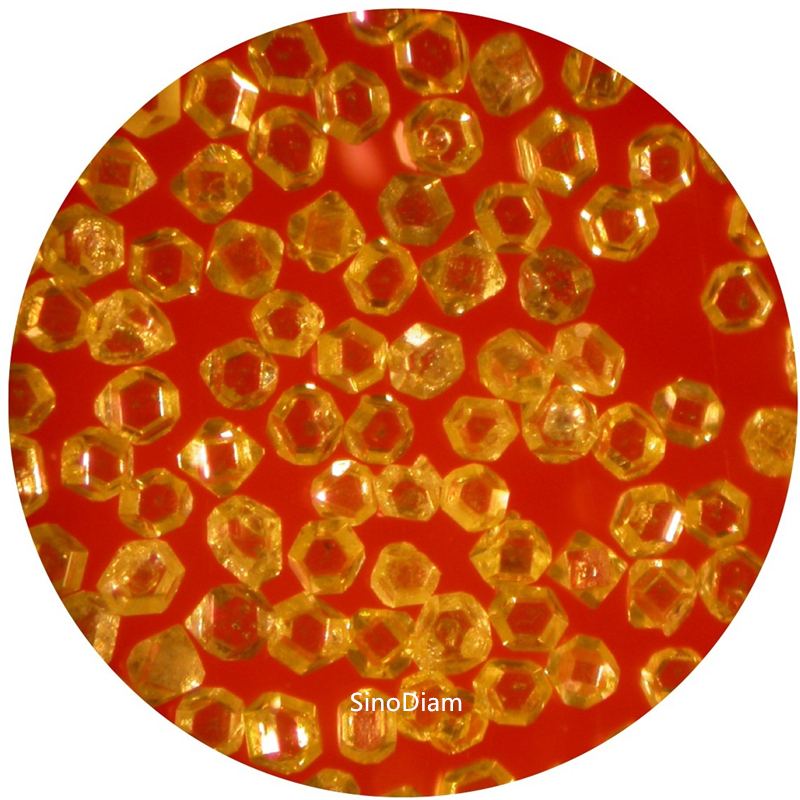

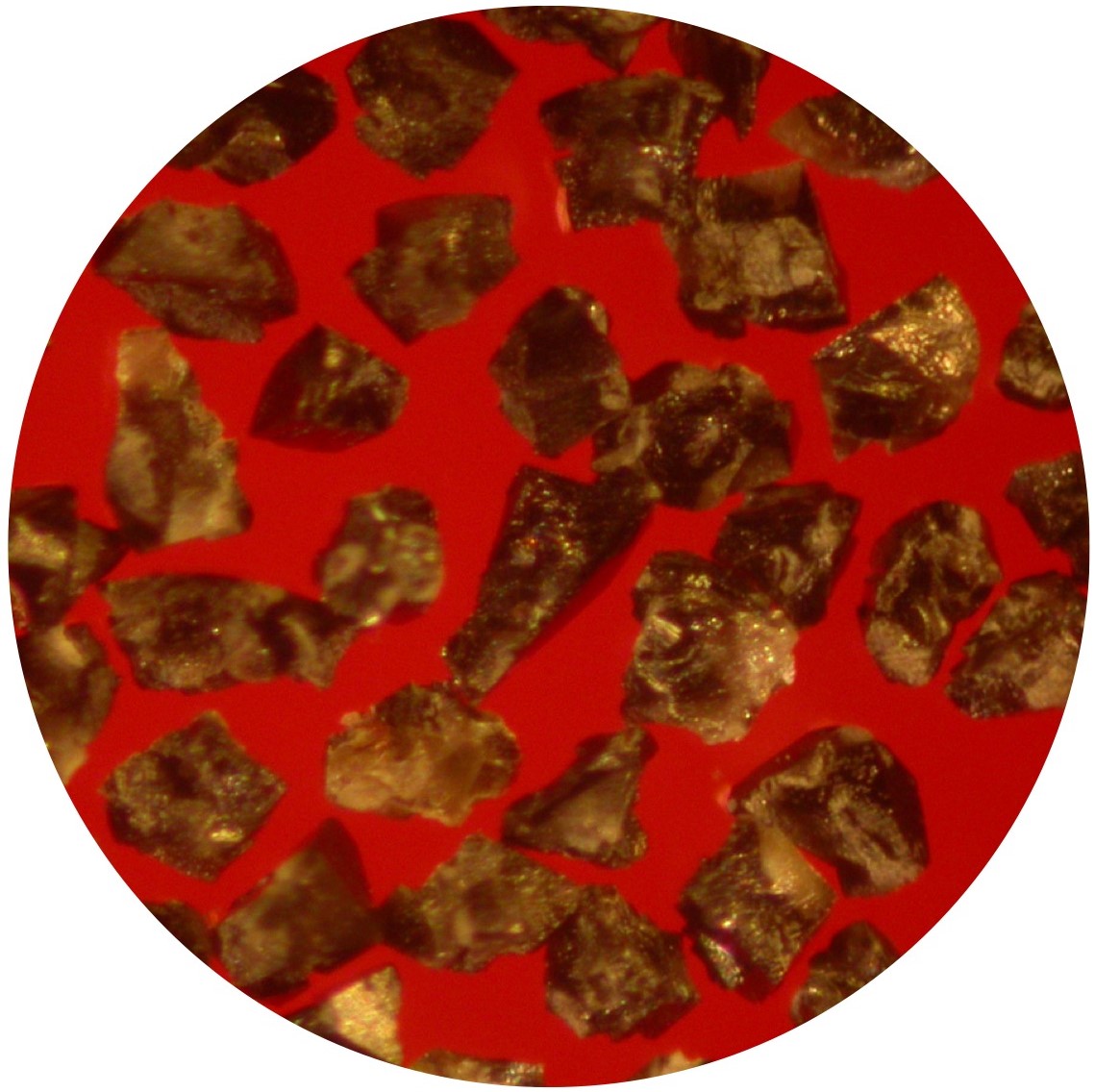

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

We'll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for High Quality for Granite Polishing Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam , The product will supply to all over the world, such as: Indonesia, Detroit, Miami, Many kinds of different products are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products with us!!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!