High Quality for Granite Polishing Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam

High Quality for Granite Polishing Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam Detail:

FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCNS03

|

Main Element | Fe, Cu, Ni, Sn |

| Theoretical Density | 7.98g/cm³ | |

| Sintering Temperature | 830℃ | |

| Bending Strength | 1150Mpa | |

| Hardness | 104-108HRB |

3. FCNS03 Character

- The Sintered structure is uniform and compact. the carcass has good control of diamond, great wear resistance and sharpness.

- The powder is applied to medium to high quality granite diamond blade, ceramic cutting blades.

4. Instructions for Making Ceramic Cutting Blade.

- Metal Percentage:

- (30-50)% FCNS03

- + (25-35)% Cu

- + (5-8)% Sn

- + (2-4)% Ni

- + Fe for Blance

B. Diamond Grit Size and Percentage:

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @ 30%

- Concentration: (9-12)%

C. Sintering Temperature: 840-860℃

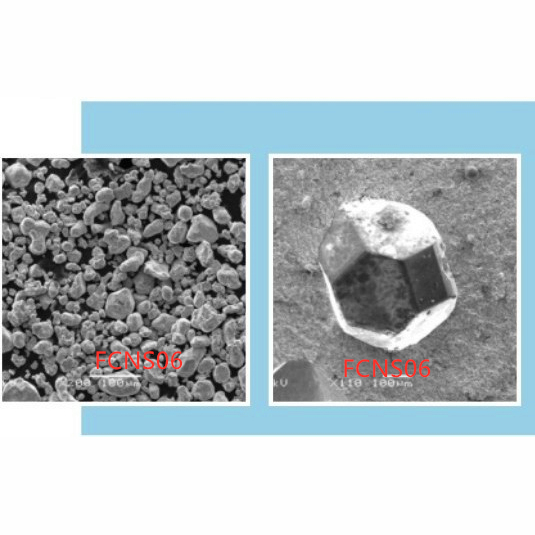

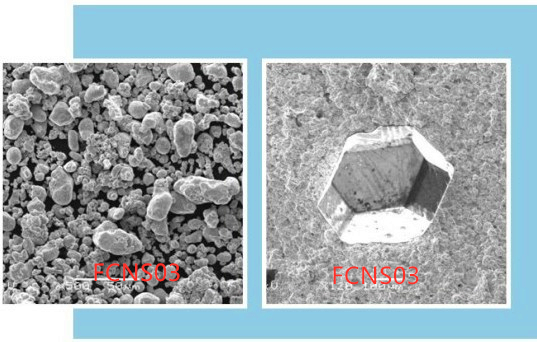

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for High Quality for Granite Polishing Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam , The product will supply to all over the world, such as: Johannesburg, Manila, Uganda, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.