High definition Titanium Coating Powder - FCP321 Pre-alloyed Powder For Medium Diameter Granite Saw Blade – SinoDiam

High definition Titanium Coating Powder - FCP321 Pre-alloyed Powder For Medium Diameter Granite Saw Blade – SinoDiam Detail:

FCP321 Pre-alloyed Powder For Medium Diameter Granite Saw Blade

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCP321

|

Main Element | Fe, Cu, P |

| Theoretical Density | 7.81g/cm³ | |

| Sintering Temperature | 850℃ | |

| Bending Strength | 1600Mpa | |

| Hardness | 105-110HRB |

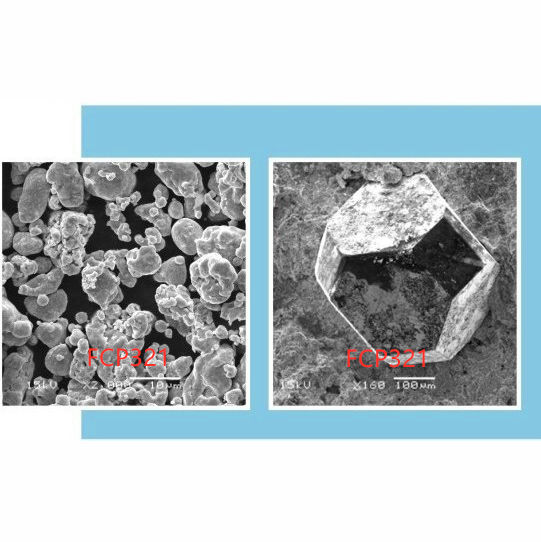

3. FCP321 Pre-alloyed Powder Character

- The Sintered Structure of the product is uniform, fine and compact, the diamond is wetted and mechanically wrapped. Low bulk density, easy cold forming and good sharpness.

- Applied to the diamond tools such as medium diameter saw blade, granite muti cutting blades, and small saw blades.

4. Usage Instruction for Medium Diamter Diamond Saw Blade

- Metal Powder

- 40-70% FCP321

- + 10-20% Cu

- + 1-3% Sn

- +5-10% Zn

- + Fe for the balance

B. Diamond

- 35/40 @ 30%

- 40/45 @ 50%

- 45/50 @20%

- Diamond Concentration @ 20-30%

C. Sintering Temperature 800-820℃

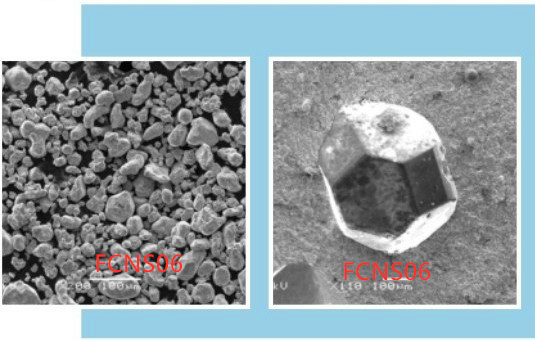

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for High definition Titanium Coating Powder - FCP321 Pre-alloyed Powder For Medium Diameter Granite Saw Blade – SinoDiam , The product will supply to all over the world, such as: Sao Paulo, Victoria, Cannes, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly