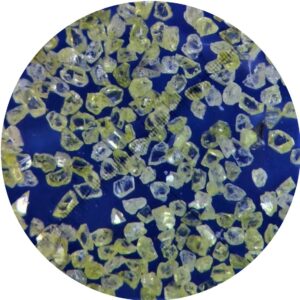

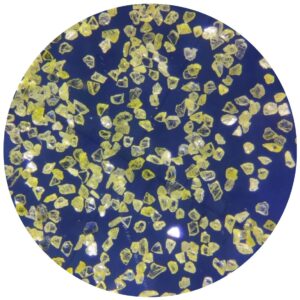

SND-G15 Premium Crushed Yellow RVD Diamond: High-Toughness for Precision Cutting & Grinding in Industrial Applications

Description:

SND-G15 is derived from ZND2115-grade natural diamond, with carbon purity ≥99.95%, offering unparalleled abrasion resistance and extended tool life. The 3-step crushing process (crystal sorting → controlled fragmentation → particle shaping) maintains superior toughness while achieving uniform granule size (±5% tolerance), preventing the uneven wear often associated with lower-grade RVD diamonds.

Key Advantages:

- Exceptional Durability: Extends tool life by 2–3x in hard rock applications (e.g., granite, basalt) compared to standard RVD diamonds. This reduces replacement frequency, especially in high-volume operations such as construction and heavy industrial grinding.

- Versatile Bond Compatibility: Perfectly suits metal bond, resin bond, and electroplating systems, offering maximum flexibility in tool manufacturing. No need for multiple diamond purchases—ideal for manufacturers working with a variety of bond types.

- Cost-Effective: Despite a slightly higher initial cost, the 40% fewer tool replacements and 30% ROI within six months significantly lower the total cost of ownership (TCO). An ideal solution for industrial users looking to reduce long-term operational costs.

Core Applications (NA/EU Focused):

- Stone Heavy-Duty Grinding Discs: Used in highway curbing and building facade projects (NA: 4,000 psi concrete; EU: C35/C40 concrete), reducing cutting tool downtime by 40%.

- Cemented Carbide Cutting Heads: Chip-free performance for automotive tungsten carbide mold cutting (e.g., EU automotive part manufacturers), ensuring precision within 0.01mm tolerance.

- Electroplated Grinding Wheels: Ideal for polishing aerospace aluminum alloy turbine blades (NA: aerospace OEMs; EU: aviation component suppliers) to Ra ≤0.8μm, reducing post-processing time by 25%.

Available Mesh Sizes:

Standard 80/100 mesh; custom sizes (60/80, 400/500 mesh) for bulk orders (MOQ: 50kg/110lbs). Custom sizes cater to specific needs, such as precision aerospace parts (400/500 mesh).

FAQ:

Q1: What mesh sizes are available for SND-G15?

A: The standard mesh size is 80/100 mesh. we offer custom sizes including 60/80 mesh for rough grinding and 400/500 mesh for precision aerospace parts.

Q2: Is SND-G15 suitable for electroplated grinding wheels?

A: Yes! SND-G15 features a uniform granule size and ≥99.95% carbon purity, ensuring strong adhesion to electroplated wheel bases. It is extensively used by NA/EU aerospace suppliers for polishing turbine blades, offering consistent performance for 80+ hours of continuous use.

Q3: How tough is SND-G15 compared to standard RVD diamonds?

A: SND-G15 offers 30% higher toughness than standard RVD diamonds. This increased durability ensures superior resistance to chipping in high-load tasks such as hard stone grinding and carbide cutting, making it the preferred choice for high-demand industrial projects where tool failure leads to costly delays.

SND-G05 Economy Crushed Green RVD | 80-500 Mesh for Stone/Ceramic/Glass Processing Tools

SND-G10 Crushed Yellow RVD Diamond | ZND2110-Grade for Stone Polishing & Resin Bond Diamond Tools

Reviews

There are no reviews yet.