SND-MDW Professional Synthetic Micron Diamond Powder: Engineered for Silicon Wafer Cutting Diamond Wire & Precision Saws

Description

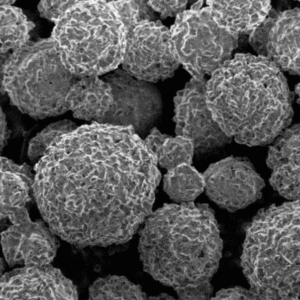

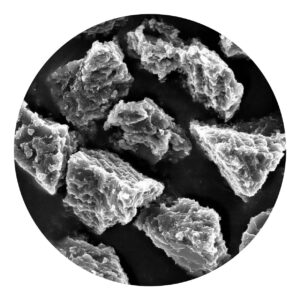

SND-MDW is specially optimized for diamond wire manufacturing, where precision, particle uniformity, and bonding strength are essential. Its blocky, high-compressive-strength crystals withstand the tension and friction of high-speed silicon wafer cutting (up to 1,500 m/min) while maintaining tight adhesion to electroplated or resin-bonded substrates.

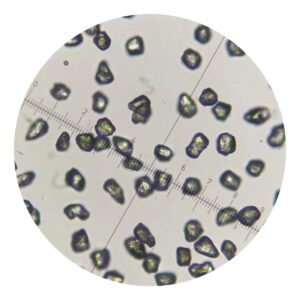

The narrow PSD range (5–20μm for wafer wire; 10–30μm for saws) ensures each diamond particle contributes evenly to the cutting force, minimizing vibration, wire wear, and wafer surface defects. Compared to generic micron diamond powders, SND-MDW extends wire life by 40%, reduces kerf width to ≤0.1mm, and improves wafer yield by up to 10%—meeting NA/EU semiconductor-grade standards (SEMI M1.13).

Technical Edge & Engineering

- Crystal Strength Enhancement: Each crystal undergoes dual thermal processing—1,100°C annealing + stress-relief treatment—raising compressive strength to 22–24 GPa, enabling superior fracture resistance during high-tension wire cutting.

- Precision PSD Control: PSD variance ≤8% ensures high coating uniformity, essential for consistent diamond wire performance across 6–12-inch wafer cutting and semiconductor slicing operations.

- Shape Uniformity & Surface Finish: 95% of particles maintain symmetrical blocky geometry, resulting in stable sawing motion and up to 25% smoother wafer surfaces (Ra ≤0.1μm).

- Thermal Endurance: Stable up to 900°C, making it compatible with metallic electroplating and high-speed resin bonding processes used in semiconductor and jewelry production lines.

Key Advantages

- ⚙️ Extended Diamond Wire Life: Achieves 40% longer service life than generic powders. A single SND-MDW-coated wire can slice 500+ 8-inch silicon wafers, lowering per-wafer cutting costs.

- 💎 Ultra-Precision Cutting: Delivers kerf width ≤0.1mm and surface roughness ≤0.1μm, meeting semiconductor and solar wafer standards for silicon, SiC, and sapphire materials.

- 🧩 Multi-Industry Compatibility: Suitable for electroplated nickel wires, resin-bond saws, and semiconductor dicing blades, ensuring high efficiency across electronic, photovoltaic, and jewelry sectors.

- 🔧 Consistent Bond Adhesion: Blocky crystals provide excellent mechanical interlocking, ensuring strong adhesion in metal and resin matrices—reducing grit shedding by 30%.

Core Applications Across Industries

Electronics & Semiconductor

- Silicon Wafer Cutting: Used in diamond wire saws for semiconductor-grade Si and SiC wafers, ensuring uniform kerf width and minimal microcracks for solar cell and chip substrate manufacturing.

- Semiconductor Dicing & Polishing: Enhances the cutting performance of semiconductor saw blades, delivering Ra ≤0.1μm finish for high-performance electronic components.

Photovoltaic Industry

- Solar Wafer Slicing: Optimized for high-efficiency solar wafer production lines, improving throughput and reducing wafer loss, ensuring consistent wafer thickness for solar PV cell assembly.

Jewelry & Gemstone Processing

- Precision Gem Cutting: Ideal for small-diameter jewelry saws (0.1–0.3mm), enabling chip-free cutting of sapphire, ruby, and emerald.

- Luxury Gem Slicing: Reduces material loss by 15%, preserving valuable gem mass while delivering mirror-smooth surfaces for further polishing.

Technical Specs

| Property | Specification |

|---|---|

| Particle Size Range | 5–20μm (silicon wire), 10–30μm (jewelry & semiconductor saws) |

| Crystal Shape | High-strength blocky |

| Compressive Strength | 22–24 GPa |

| PSD Concentration | Variance ≤8% |

| Bond Compatibility | Electroplated nickel, resin bond |

| Thermal Stability | Up to 900°C |

FAQ

Q1: What particle size of SND-MDW is best for silicon wafer diamond wire?

A: The 5–20μm range is optimized for high-precision semiconductor and solar wafer cutting, balancing cutting speed and kerf control. For thicker wafers (>12-inch), 10–15μm is recommended for enhanced durability.

Q2: Can SND-MDW be used in resin-bonded jewelry saws?

A: Absolutely. Its blocky structure ensures excellent retention in resin matrices, preventing grit pull-out and allowing smooth cutting of sapphire, ruby, and emerald without chipping.

Q3: How does SND-MDW improve diamond wire durability?

A: Its 22–24 GPa compressive strength and uniform PSD minimize internal stress points, reducing wire breakage by up to 30% during high-tension cutting operations.

Q4: Is SND-MDW suitable for solar wafer production?

A: Yes—it’s widely used in PV wafer slicing due to its consistent kerf width, low material loss, and compatibility with high-speed wire coating systems.

Q5: What’s the shelf life and storage recommendation?

A: 36 months in vacuum-sealed aluminum bags. Store at 15–25°C, <60% humidity. Keep away from oils or solvents to preserve surface purity and bonding performance.

SND-MPL Polycrystalline Synthetic Micron Diamond Powder

Avis

Il n’y a pas encore d’avis.