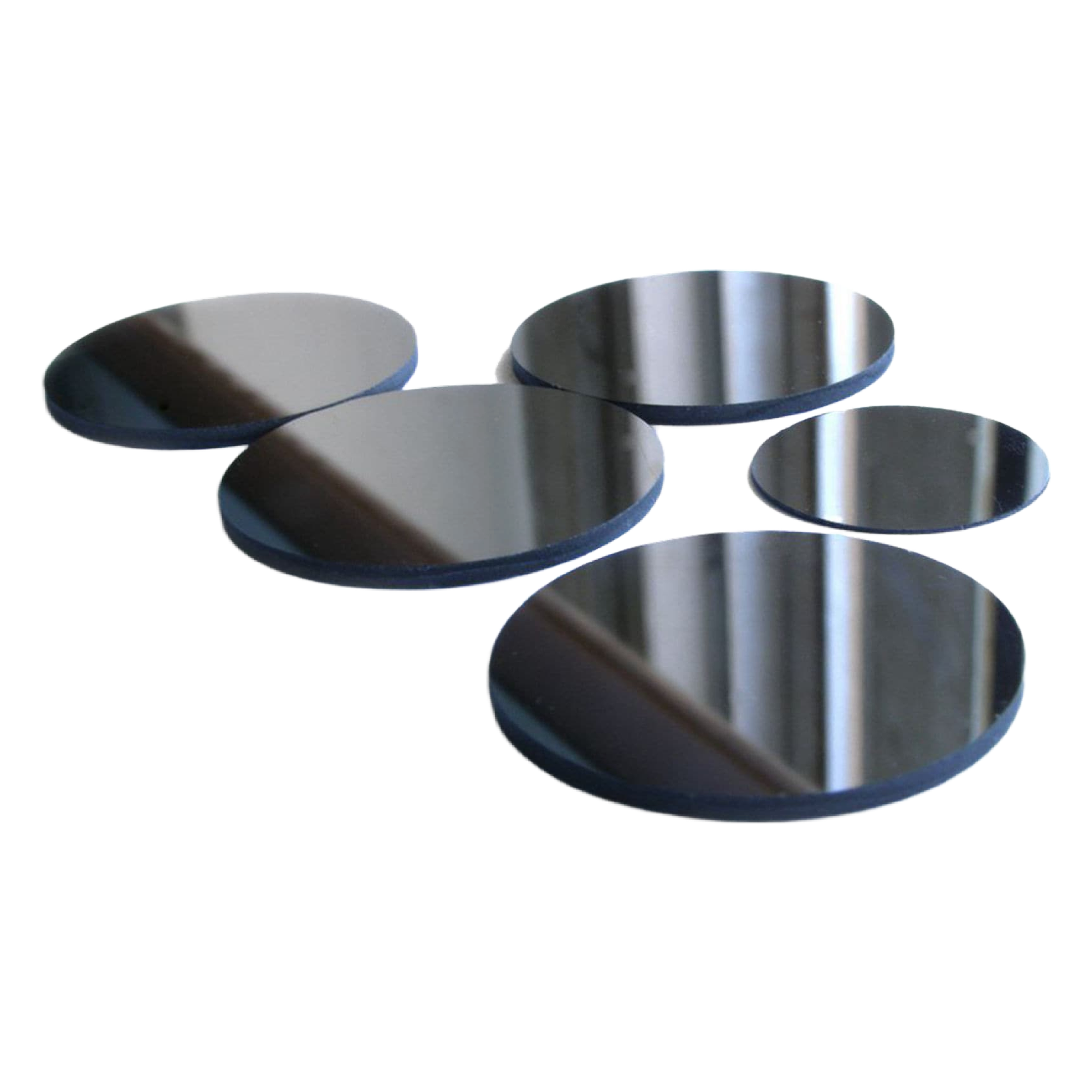

Polycrystalline Diamond (PCD) tools from SionDiam International are designed for the precision machining of non-ferrous metals, alloys, and non-metallic materials like aluminum, copper, ceramics, wood, chipboard, and rubber. PCD tools are renowned for their high abrasion resistance, excellent surface finishes, and long tool life, making them the ideal choice for industries such as automotive, aerospace, electronics, and woodworking.

Our PCD tools are used in applications that demand high-performance machining, offering exceptional wear resistance for demanding materials like silicon carbide, high-silica aluminum alloys, and carbon fiber composites. With customizable diamond segment sizes, SionDiam offers tailored solutions to meet your specific needs, ensuring optimal performance for each application.

Key Features of SionDiam PCD Tools:

High Abrasion Resistance: Ideal for machining hard and abrasive materials

Excellent Surface Finish: Produces smooth, high-quality finishes

Impact Toughness: Provides enhanced durability in tough conditions

Customizable: Available in a range of diamond segment sizes to fit specific applications

Versatile Applications: Suitable for woodworking, chipboard processing, ceramics, plastics, and non-ferrous metals

Product Range and Specifications:

| Code # | Diameter (mm) | Diamond Layer (mm) | Height (mm) | Diamond Size (μm) | Features | Application |

|---|---|---|---|---|---|---|

| SDPD032-A | 48.0 | 0.5 ± 0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 30+2 | Extremely high abrasive resistance. Impact toughness is strengthened by the order of 025-A,025-B,032-A and 032-B, EDM cutting performance is strengthened by the order of 025-A,032-A,032-B and 025-B | Used in highly abrasive materials such as ceramics, silicon carbide, stone, laminate flooring, and hard metals. |

| SDPD032-B | 48.0 | 0.5 ± 0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 30+2 | Extremely high abrasive resistance. Impact toughness is strengthened by the order of 025-A,025-B,032-A and 032-B, EDM cutting performance is strengthened by the order of 025-A,032-A,032-B and 025-B | Ideal for chipboard, laminate, and rough-feed cutting needs. |

| SDPD025-A | 48.0 | 0.5 ± 0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 25 | Extremely high abrasive resistance. Impact toughness is strengthened by the order of 025-A,025-B,032-A and 032-B, EDM cutting performance is strengthened by the order of 025-A,032-A,032-B and 025-B | Suitable for laminate flooring, density boards, carbon fiber materials, silicon carbide, and high-silica aluminum alloys. |

| SDPD025-B | 48.0 | 0.5 ± 0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 25 | Extremely high abrasive resistance. Impact toughness is strengthened by the order of 025-A,025-B,032-A and 032-B, EDM cutting performance is strengthened by the order of 025-A,032-A,032-B and 025-B | Used in manufacturing of wood saw blades and products requiring EDM cutting. |

| SDPD012-A | 48.0 | 0.5 ± 0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 10+2 | Combining high abrasive resistance, impact toughness and high degree of surface finish. Abrasive resistance is strengthened by the order of 010-C,010-B,012-A and 010-A. Impact toughness is 010-A,012-A,010-B and 010-C, EDM cutting performance is 010-A,012-A,010-C and 010-B. | Ideal for circuit board processing, silicon-aluminum alloys, and copper alloys. |

| SDPD010-A | 48.0 | 0.5 ± 0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 10 | Combining high abrasive resistance, impact toughness and high degree of surface finish. Abrasive resistance is strengthened by the order of 010-C,010-B,012-A and 010-A. Impact toughness is 010-A,012-A,010-B and 010-C, EDM cutting performance is 010-A,012-A,010-C and 010-B. | Used for wood, circuit boards, low-silicon aluminum alloys, and fine ceramics. |

| SDPD010-B | 48.0 | 0.5 ± 0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 10 | Combining high abrasive resistance, impact toughness and high degree of surface finish. Abrasive resistance is strengthened by the order of 010-C,010-B,012-A and 010-A. Impact toughness is 010-A,012-A,010-B and 010-C, EDM cutting performance is 010-A,012-A,010-C and 010-B. | Ideal for manufacturing segments requiring EDM cutting. |

| SDPD010-C | 48.0 | 0.5 ± 0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 10 | Combining high abrasive resistance, impact toughness and high degree of surface finish. Abrasive resistance is strengthened by the order of 010-C,010-B,012-A and 010-A. Impact toughness is 010-A,012-A,010-B and 010-C, EDM cutting performance is 010-A,012-A,010-C and 010-B. | Used in applications requiring rough feed and low abrasive resistance. |

| SDPD005-A | 48.0 | 0.5 ± 0.15 | 1.0/1.2/1.6/2.0/2.5/3.2 | 5 | High impact toughness, suitable for EDM cutting, extremely high degree of surface finish. | Ideal for low-silicon aluminum alloys, non-ferrous metals, semiconductors, and plastics. |

Applications:

SionDiam’s PCD tools are ideal for precision machining in various industries:

Machining Non-Ferrous Metals: Aluminum, copper, brass, and more

Woodworking & Carpentry: For cutting and finishing chipboard, plywood, and other wood-based materials

Ceramics & Glass: Used for high-precision cutting and polishing in ceramics and glass industries

Plastics & Rubber: For machining plastics, rubber, and composite materials

Electronics & Aerospace: Ideal for fine processing of circuit boards, silicon-based materials, and aerospace components

Automotive & Tool Manufacturing: For cutting and grinding high-performance carbon fiber composites and silicon carbide

Why Choose SionDiam’s PCD Tools?

Exceptional Wear Resistance: Our PCD tools offer longer tool life and improved machining efficiency.

Customizable Diamond Segments: We provide tools that can be customized in size and shape to meet specific needs, ensuring optimal cutting performance.

High-Precision Finishing: PCD tools deliver superior surface finishes and high cutting accuracy.

Eco-Friendly & Cost-Effective: As a sustainable alternative to traditional materials, PCD tools reduce waste and increase profitability for your business.

PCBN Composites: High-Performance Cutting Tools for Hard Materials

marmolesonak –

I recently upgraded to a PCD (polycrystalline diamond) saw blade for my aluminum cutting projects, and I’m genuinely impressed. Compared to the traditional carbide blade I was using, this PCD blade delivers cleaner cuts, significantly longer life, and far less wear. The difference in performance is night and day—no more frequent sharpening or worrying about chipped teeth.

What really stood out is how effortlessly it slices through aluminum, leaving smooth edges with minimal burrs. It’s made my workflow faster and more precise, and I’ve already noticed a boost in productivity.

If you’re serious about aluminum work and want a blade that lasts, this PCD option is absolutely worth the investment. Highly recommended!