SND-M10 Micron Diamond: High-Performance, Multi-Material Grinding & Polishing for Natural Diamonds, Gems, Glass, Ceramic, and Diamond Paste

Description

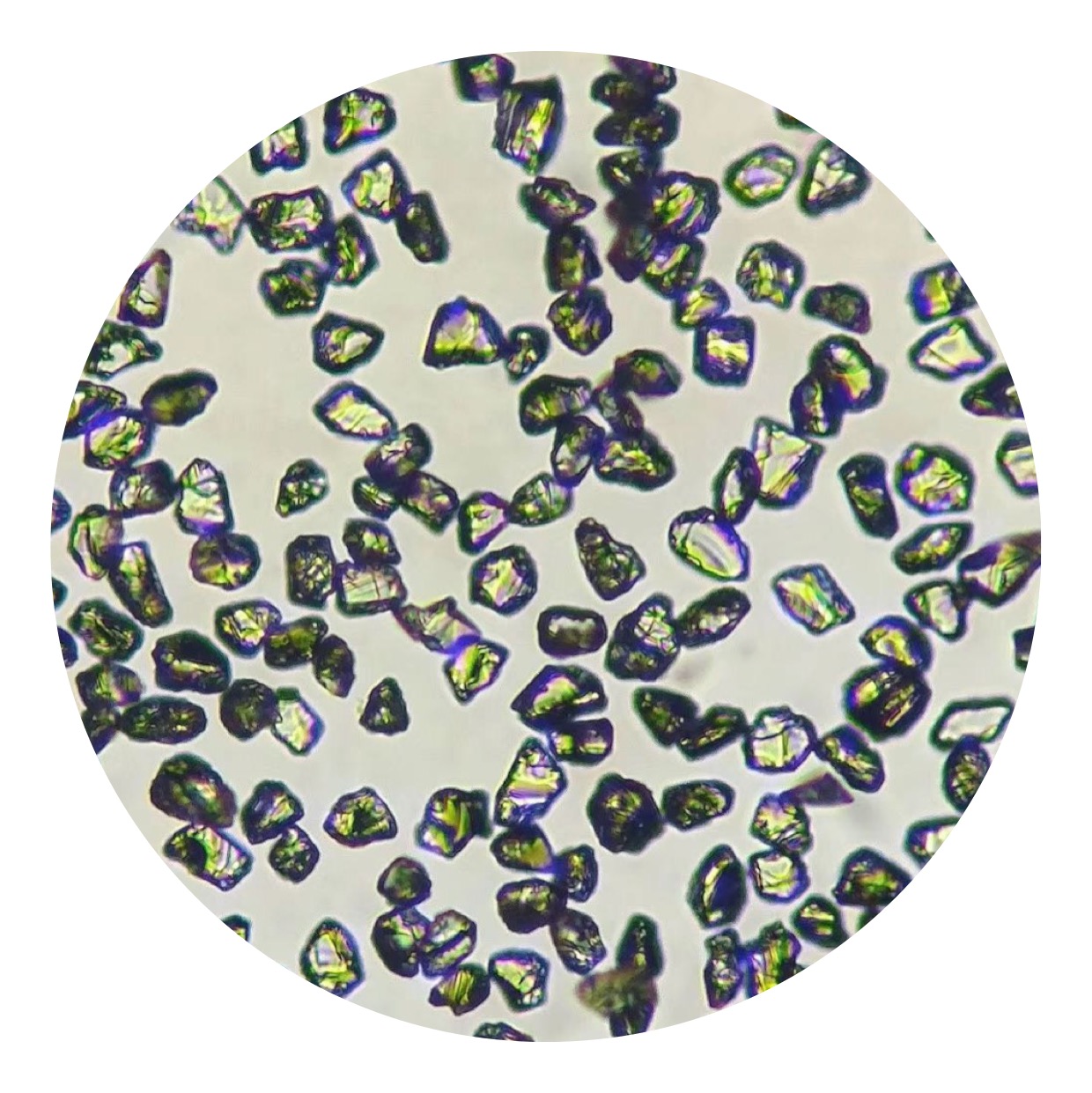

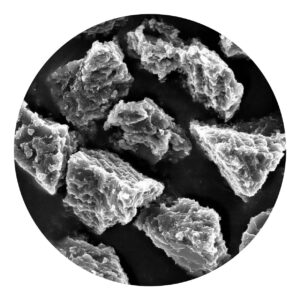

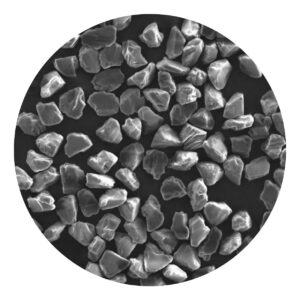

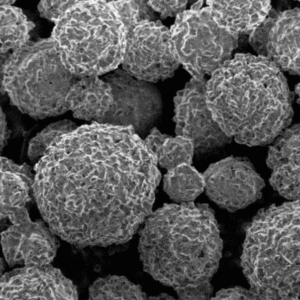

SND-M10 is defined by its irregular crystal structure and a relatively concentrated particle size distribution ranging from 0–0.125~40–60μm. It is meticulously engineered with a minimal impurity content (total impurities ≤0.3%), offering enhanced efficiency for processing materials like natural diamonds, gems, glass, and ceramics. The product’s adaptability to resin, vitrified, metal, and electroplated bonds eliminates the need for multiple diamond grades, making it a cost-effective solution for businesses in need of versatile, high-performance diamond grit.

Technical Edge & Engineering

- Crystal & Impurity Control: The irregular crystal shapes and tightly controlled particle size range optimize material interaction, ensuring precision during the cutting and polishing of natural diamonds, gems, and ceramics. The low impurity content (N ≤0.2%, B ≤0.05%) reduces the risk of surface defects, ensuring smooth finishes across materials.

- Particle Size Distribution (PSD): The focused PSD minimizes surface unevenness by 20% compared to diamonds with broader PSDs, delivering a higher level of precision and consistency. This is particularly important for multi-material processing, where uniformity is key.

- Thermal Stability & Wear Rate: Withstanding temperatures up to 750°C, SND-M10 is suitable for use in metal-bonded applications. It offers a significantly lower wear rate (0.8–1.0% mass per hour) in natural diamond cutting compared to generic mid-tier diamonds, prolonging tool life and enhancing productivity.

Key Advantages

- Multi-Material Efficiency: SND-M10 increases material removal efficiency by 25% compared to SND-M05, especially in natural diamond cutting and ceramic grinding. This results in faster, smoother processes with reduced chipping and fracturing, improving yield by 15%.

- Bond Flexibility: Compatible with a wide range of bond systems—resin, vitrified, metal, and electroplated—SND-M10 offers unparalleled flexibility for businesses with varied tooling needs, reducing the need for multiple diamond grades.

- Cost-Performance Balance: Priced 30% lower than premium SND-M15, SND-M10 delivers approximately 80% of the performance, making it an excellent choice for businesses scaling up production without exceeding budget constraints.

Core Applications Across Industries

- Natural Diamond Processing:

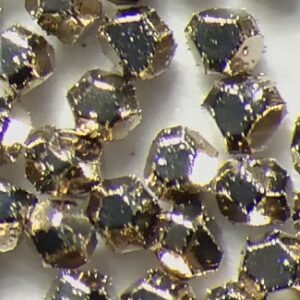

- Small Gem Labs: SND-M10 is perfect for cutting and shaping rough natural diamonds, minimizing material loss and maximizing yield for high-quality jewelry production.

- Gem, Glass, and Ceramic Work:

- Gemstone Polishing: Efficiently polishes sapphires, rubies, and other precious gems, reducing the need for secondary polishing processes and improving overall production time.

- Glass Grinding: SND-M10 provides precise grinding for glass panels, ensuring smooth edges without chipping or fracturing, ideal for architectural and decorative glass applications.

- Ceramic Edging: It ensures precise edging and dimensional accuracy for ceramic tiles and insulators, making it ideal for high-precision ceramic applications.

- Diamond Paste and Slurry Formulation:

- Mid-Grade Formulations: SND-M10 is an excellent choice for formulating mid-range diamond paste and slurry, providing consistent grit distribution for hand-polishing tools and ensuring a smooth, high-gloss finish.

Technical Specs

- Particle Size Range: 0–0.125~40–60μm

- Crystal Shape: Irregular (concentrated size distribution)

- Bond Compatibility: Resin, Vitrified, Metal, Electroplated

- Toughness: ★★ (Double Yellow Bars)

- Thermal Stability: Up to 750°C

- Impurity Content: ≤0.3% (Nitrogen ≤0.2%, Boron ≤0.05%)

FAQ

Q1: Why use SND-M10 for diamond paste?

A: SND-M10’s tightly controlled particle size and minimal impurities provide consistent grit distribution in diamond paste, ensuring smoother polishing results and reducing the need for secondary polishing. It offers an affordable alternative to premium grades for mid-range formulations.

Q2: Can SND-M10 be used in metal-bond tools?

A: Yes, SND-M10’s crystal structure bonds well with metal matrices, making it ideal for metal-bonded grinding tools used in applications like ceramic and glass fabrication.

Q3: How does SND-M10 improve natural diamond processing?

A: SND-M10 reduces chipping and fracturing in natural diamond cutting, preserving material integrity and boosting yield by up to 15% compared to lower-grade diamonds.

Q4: What’s the shelf life and storage recommendation for SND-M10?

A: SND-M10 has a shelf life of 36 months when stored in sealed, moisture-proof packaging. It should be kept at temperatures between 15–28°C and humidity levels below 65%. After opening, reseal the package tightly to maintain the integrity of the particles.

SND-MAG Diamond Agglomerated Micron Powder

Avis

Il n’y a pas encore d’avis.