FCCS07 FeCuCoSn Pre Alloyed Metal Powde for Medium to High Quality Diamond Tools

FCCS07 FeCuCoSn Pre Alloyed Metal Powde for Medium to High Quality Diamond Tools

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCCS07

|

Main Element | Fe, Cu, Co, Sn |

| Theoretical Density | 7.84g/cm³ | |

| Sintering Temperature | 790℃ | |

| Bending Strength | 1500Mpa | |

| Hardness | 105-110HRB |

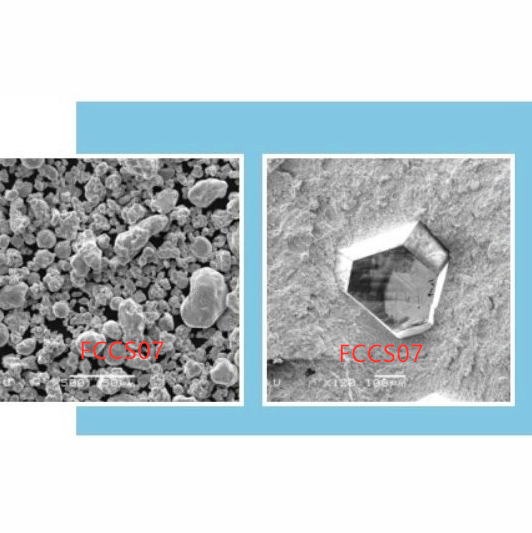

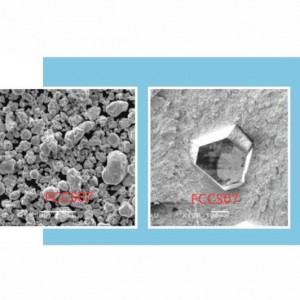

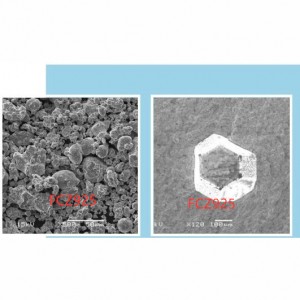

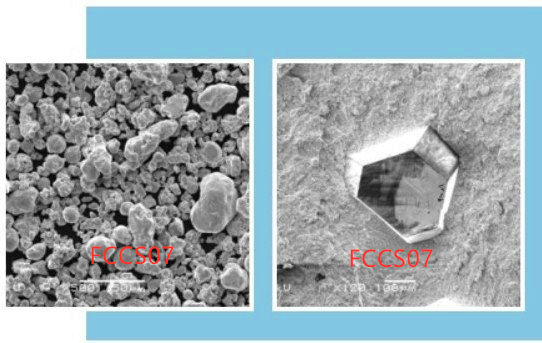

3. FCCS07 Pre-alloyed Powder Character

- The powder has good wetting ability to the diamond and great mechanical granulating to other metal powders, it can help the products achieve a great value on speed and life.

- Applied to medium to high quality granite diamond blade, ceramic diamond blade, diamond wire and diamond core bits

4. Usage Instruction for Ceramic Cutting Blade

- Metal Powder

- 30-50% FCCS07

- + 25-35% Cu

- + 3-6% Sn

- +2-5% Ni

- +7-10% CUCS

- + Fe for the balance

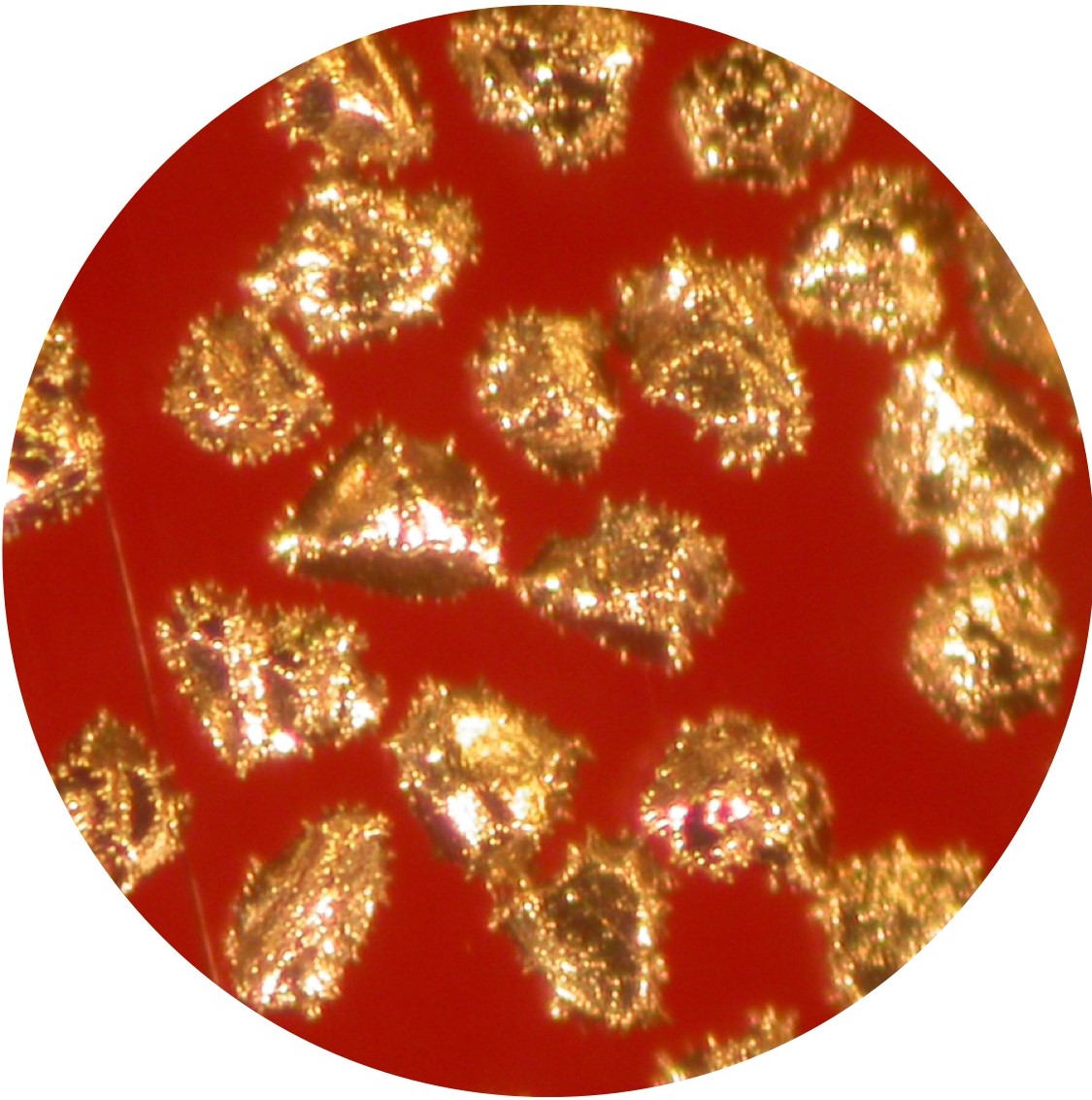

B. Diamond for Dry Cutting Ceramic

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @30%

- Diamond Concentration @ 13-15%

C. Diamond for Wet Cutting Ceramic

- 50/60 @ 60%

- 60/70 @ 40%

- Diamond Concentration @ 10-12%

D. Sintering Temperature 830-850℃