Fast delivery Diamond Lapping Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam

Fast delivery Diamond Lapping Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam Detail:

FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCNS03

|

Main Element | Fe, Cu, Ni, Sn |

| Theoretical Density | 7.98g/cm³ | |

| Sintering Temperature | 830℃ | |

| Bending Strength | 1150Mpa | |

| Hardness | 104-108HRB |

3. FCNS03 Character

- The Sintered structure is uniform and compact. the carcass has good control of diamond, great wear resistance and sharpness.

- The powder is applied to medium to high quality granite diamond blade, ceramic cutting blades.

4. Instructions for Making Ceramic Cutting Blade.

- Metal Percentage:

- (30-50)% FCNS03

- + (25-35)% Cu

- + (5-8)% Sn

- + (2-4)% Ni

- + Fe for Blance

B. Diamond Grit Size and Percentage:

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @ 30%

- Concentration: (9-12)%

C. Sintering Temperature: 840-860℃

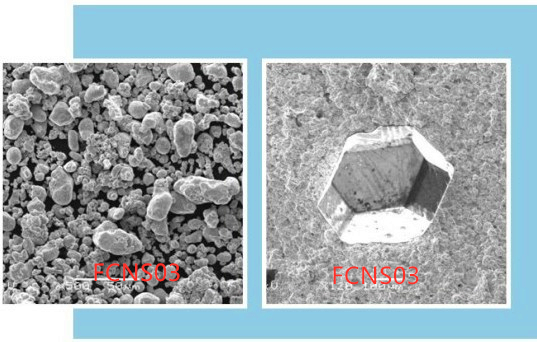

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

Together with the "Client-Oriented" enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy R&D staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for Fast delivery Diamond Lapping Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam , The product will supply to all over the world, such as: Slovak Republic, Portugal, Amsterdam, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.