Factory wholesale Diamond Fast Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam

Factory wholesale Diamond Fast Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam Detail:

FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCNS03

|

Main Element | Fe, Cu, Ni, Sn |

| Theoretical Density | 7.98g/cm³ | |

| Sintering Temperature | 830℃ | |

| Bending Strength | 1150Mpa | |

| Hardness | 104-108HRB |

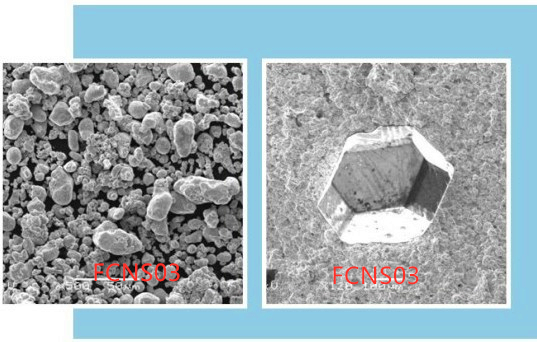

3. FCNS03 Character

- The Sintered structure is uniform and compact. the carcass has good control of diamond, great wear resistance and sharpness.

- The powder is applied to medium to high quality granite diamond blade, ceramic cutting blades.

4. Instructions for Making Ceramic Cutting Blade.

- Metal Percentage:

- (30-50)% FCNS03

- + (25-35)% Cu

- + (5-8)% Sn

- + (2-4)% Ni

- + Fe for Blance

B. Diamond Grit Size and Percentage:

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @ 30%

- Concentration: (9-12)%

C. Sintering Temperature: 840-860℃

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Factory wholesale Diamond Fast Powder - FCNS03 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Diamond Blade – SinoDiam , The product will supply to all over the world, such as: Malaysia, Lithuania, Manchester, We have to continue to uphold the "quality, comprehensive, efficient" business philosophy of "honest, responsible, innovative"spirit of service, abide by the contract and abide by reputation, first-class products and improve service welcome overseas customers patrons.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!