Factory Supply Diamond Dust Powder - FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel – SinoDiam

Factory Supply Diamond Dust Powder - FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel – SinoDiam Detail:

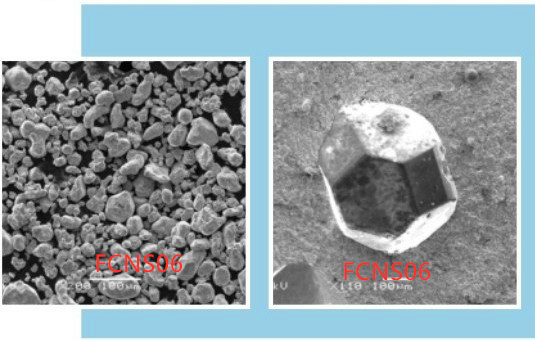

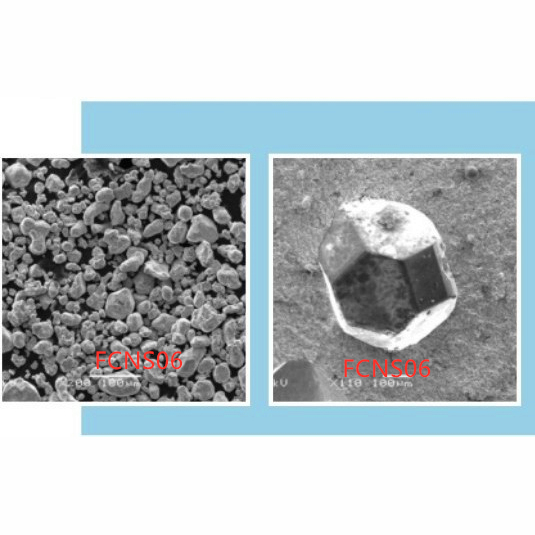

FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel

1. What is Pre-alloyed Powder

Pre-alloyed powders are harder, less compressible and hence require higher pressing loads to produce high density compacts. However, they are capable of producing high strength sintered materials. Pre-alloying is also used when the production of a homogeneous material from elemental powders requires very high temperatures and long sintering times. The best examples are the stainless steels, whose chromium and nickel contents have to be pre-alloyed to allow economic production by powder metallurgy.

2. The Parameters of FCNS06

|

Main Element | Fe, Cu, Ni, Sn |

| Theoretical Density | 8.05g/cm³ | |

| Sintering Temperature | 810℃ | |

| Bending Strength | 1100Mpa | |

| Hardness | 105-110HRB |

3. FCNS06 Character

- The Sintered structure of the product is uniform, fine and compact, it has good wetting and holding powder to the diamond, high hardness of the carcass, excellent wear resistance and good comprehensive performance of tools.

- The powder is applied to high quality small diameter diamond saw blade, ceramic cutting blades, ceramic gridning squaring wheel and scrapers.

4. Instructions for Making Ceramic Squaring Wheels.

- Metal Percentage:

- (40+60)% FCNS06

- + (15-25)% Cu

- + (6-10)% Sn

- + (2-5)% Ni

- + (8-12)% 663

- + Fe for Blance

B. Diamond Grit Size and Percentage:

- 70/80 @ 60%

- 80/100 @ 40%

- Concentration: (18-22)%

C. Sintering Temperature: 750-770℃

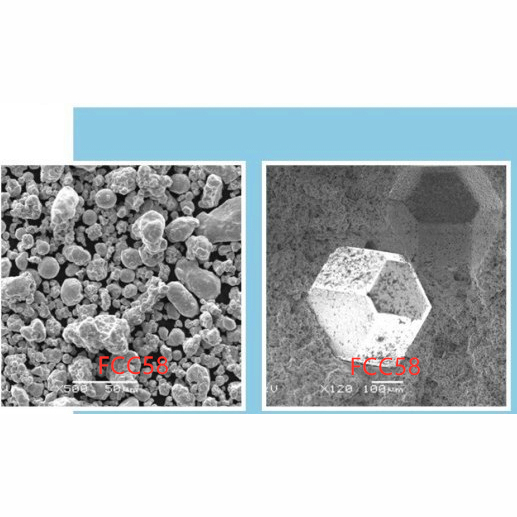

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

Sticking towards the principle of "Super High-quality, Satisfactory service" ,We've been striving to become a superb business partner of you for Factory Supply Diamond Dust Powder - FCNS06 Fe Cu Ni Sn Pre Alloyed Powder for Ceramic Squaring Wheel – SinoDiam , The product will supply to all over the world, such as: Morocco, Qatar, South Korea, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.