Factory Free sample Rough Diamond - Diamond Lapping Abrasive Paste Diamond Compound for Polishing – SinoDiam

Factory Free sample Rough Diamond - Diamond Lapping Abrasive Paste Diamond Compound for Polishing – SinoDiam Detail:

Polycrystalline diamond paste for precision polishing, Oil soluble.

Good wettability, strong grinding force, suitable for processing of equipment, measuring devices, knives,

grinding tools and seals that are made from super hard materials like hard alloy, alloy steel and carbon

steel.

- Name: Diamond Polishing Compound

- Brand: SND-PC

- Mesh: 0-0.25~40-60

- Diamond Percentage: 10%, 25%, 50%

- Application: Suitable for the grinding and polishing of metals, tungsten carbide, mold, alloys, glass, ceramics, semiconductors, jade, and other hard

materials. - Package: 5g syringe/10g/50g plastic bottles/upon request.

Available Size and Application

|

Synthetic diamond micro powder (µm) |

Mesh |

Usage |

|

|

W0.25 |

(0-0.5) |

#60,000 |

For Super mirror polishing |

|

W0.5 |

(0-1) |

#28,000 |

|

|

W1 |

(0-2) |

#14,000 |

|

|

W3 |

(2-4) |

#8,000 |

|

|

W4.5 |

(3-6) |

#5,000 |

For Precision brightness |

|

W6 |

(4-8) |

#3,000 |

|

|

W8 |

(6-10) |

#2,000 |

|

|

W9 |

(6-12) |

#1,800 |

|

|

W13 |

(10-16) |

#1,500 |

For General brightness |

|

W15 |

(10-20) |

#1,200 |

|

|

W17.5 |

(15-20) |

#1,000 |

|

|

W25 |

(20-30) |

#800 |

For Coarse grinding |

|

W35 |

(30-40) |

#600 |

|

|

W50 |

(40-60) |

#400 |

|

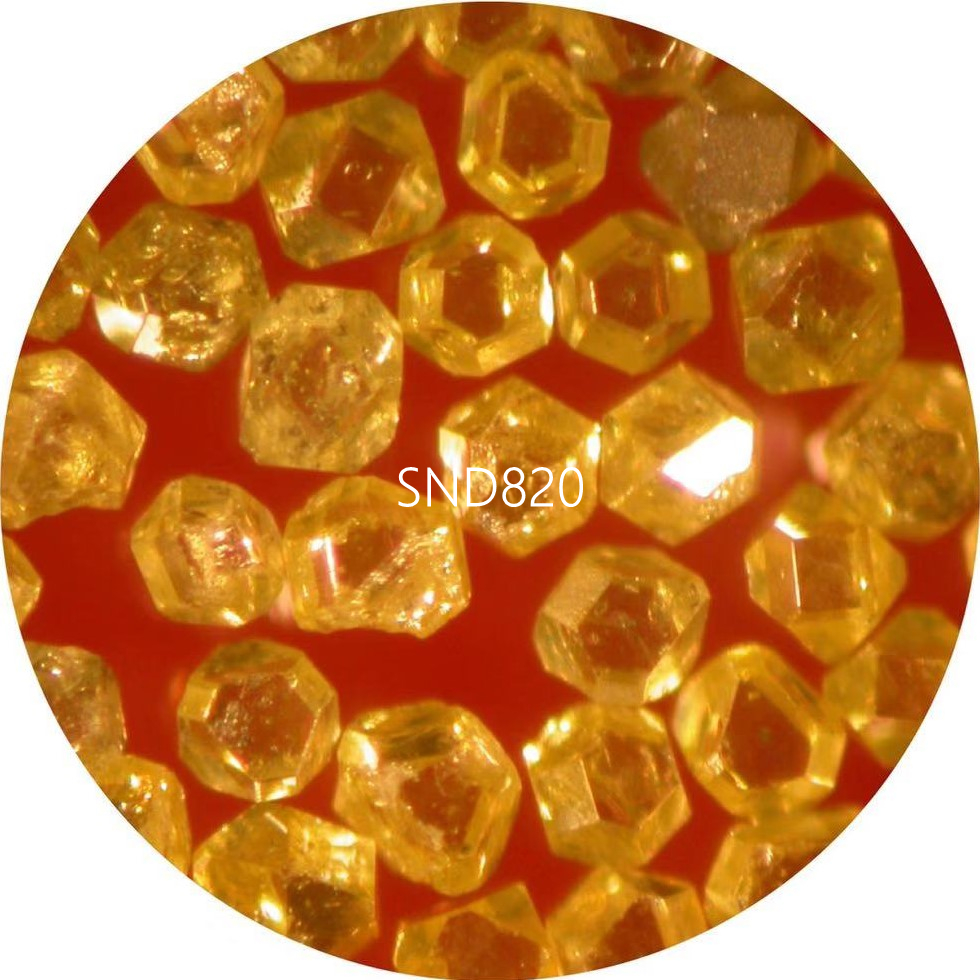

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for Factory Free sample Rough Diamond - Diamond Lapping Abrasive Paste Diamond Compound for Polishing – SinoDiam , The product will supply to all over the world, such as: Hanover, Cape Town, Manchester, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

Write your message here and send it to us