Factory best selling Diamond Grinding Disc - Polycrystalline Diamond Compact PDC Cutter For Concrete and Asphalt Milling Bits – SinoDiam

Factory best selling Diamond Grinding Disc - Polycrystalline Diamond Compact PDC Cutter For Concrete and Asphalt Milling Bits – SinoDiam Detail:

PDC Cutter For Concrete and Asphalt Milling Bits

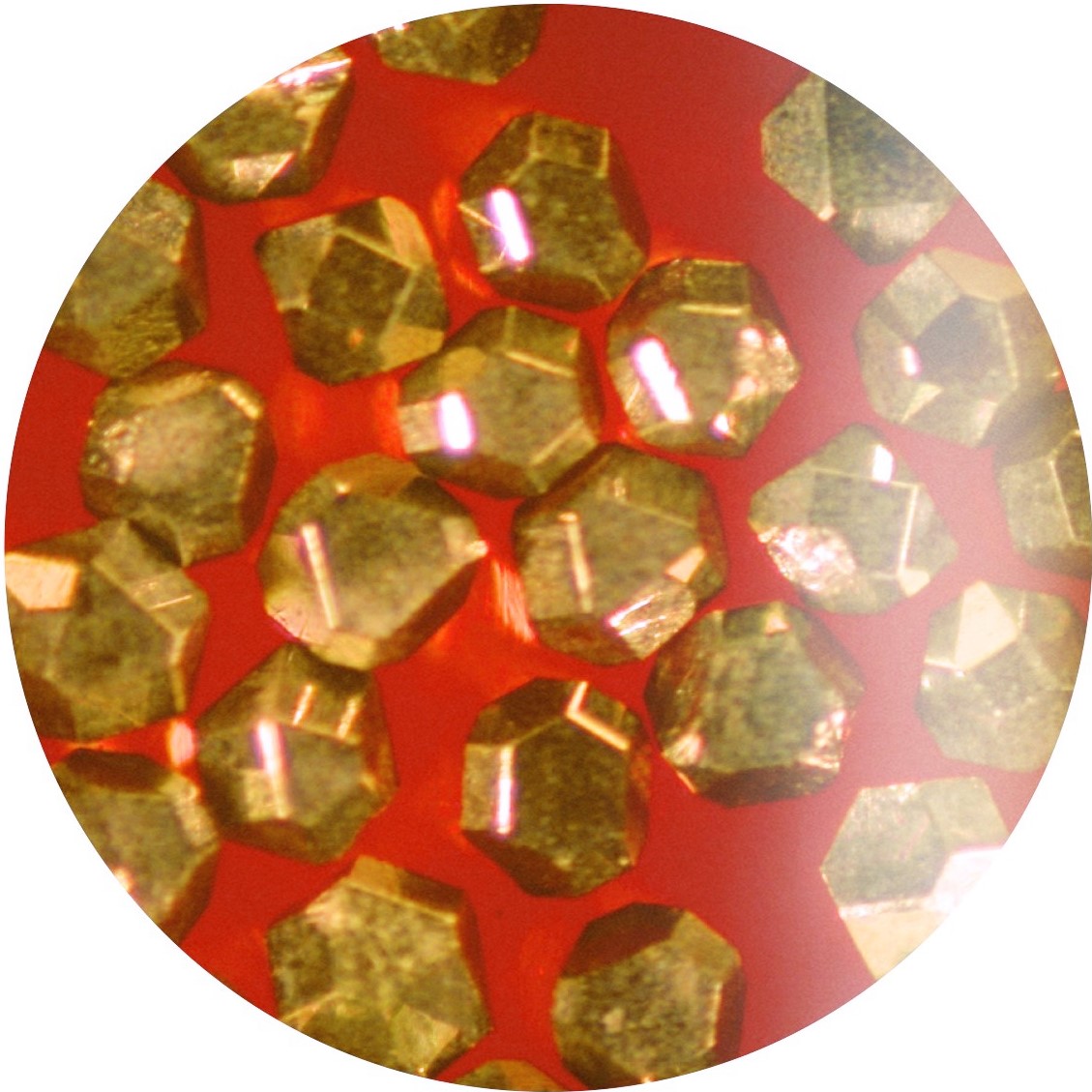

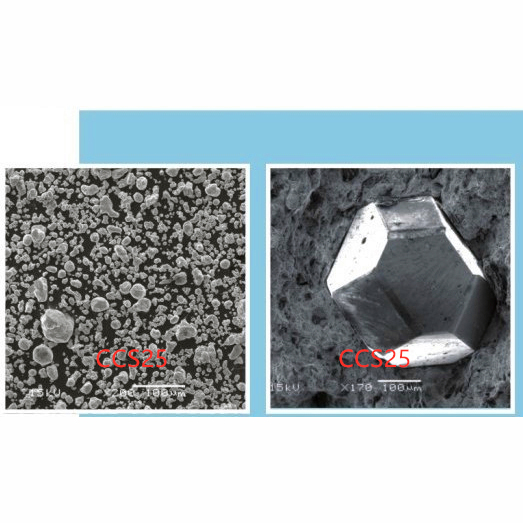

1. What is PDC- Polycrystalline Diamond Compact?

PDC- Polycrystalline diamond compact is composed of polycrystalline diamond layer and tungsten carbide substrate, the polycrystalline diamond layer possesses extremely high hardness and abrasion resistance whereas the tungsten carbide substrate would greatly improve the malleability and weld ability of the whole composite, the polycrystalline diamond compost is used oil well drilling petroleum, geology exploring, coalfield mining and mechanical industry.

PDC cutters for geological mining field drilling bits series are designed for markets in the pursuing of cost. This series PDC are mainly used for producing anchor-shank drill bits, which are equipped with sharp edge, fast footage, high effectiveness, stability, economical and practical advantages.

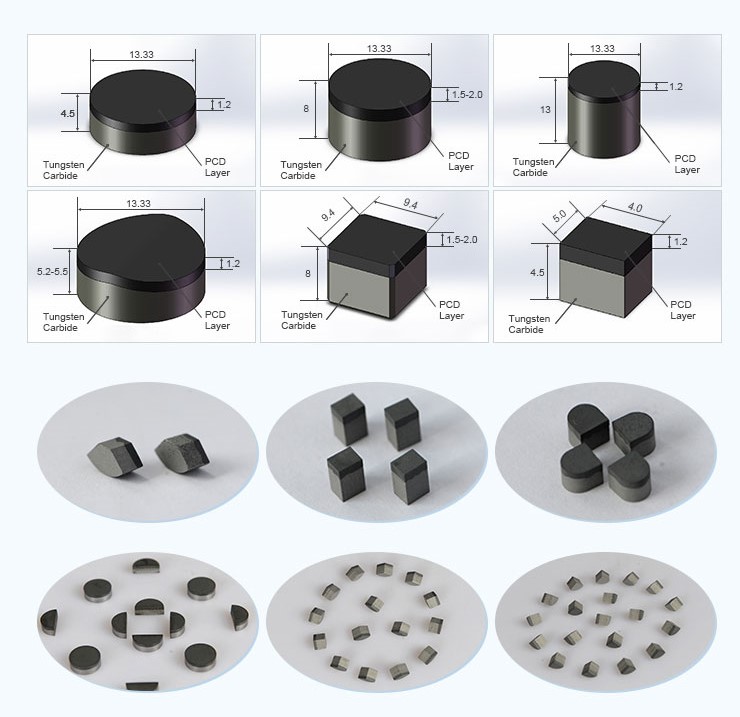

2. Specificaiton and Application of the PDC cutter

| PDC cutter for Coal Mining, Geological Exploration, Stone Processing, Road Milling | |||

| Model | 0808, 1004, 1008, 1204, 1304, 1308, 1313, 1608, 1613, 1616, 1908, 1913,1916, 1919 | 1306, 1308 | 1305, 1308 |

| Application | Making geological and coalmine drill bits for medium-hard rocks | Making geological& coalmine drill bits for soft rocks | Making geological& coalmine drill bit for hard rocks |

| Advantages | High wear resistance and impact resistance. | Faster rock breaking speed in soft rocks | Longer useful life, and High impact resistance in hard rocks |

3. Other PDC Cutter Shapes

Product detail pictures:

Related Product Guide:

Wu Jianzhong: Pay attention to innovation, focus on high-end, and promote the transformation and upgrading of superhard industry

we can easily offer you high-quality products and solutions, competitive rate and very best shopper support. Our destination is "You come here with difficulty and we give you a smile to take away" for Factory best selling Diamond Grinding Disc - Polycrystalline Diamond Compact PDC Cutter For Concrete and Asphalt Milling Bits – SinoDiam , The product will supply to all over the world, such as: Egypt, Nairobi, Luxembourg, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!