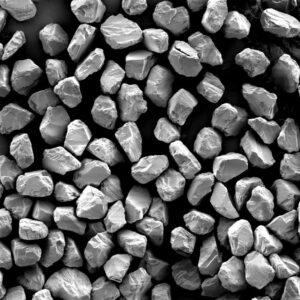

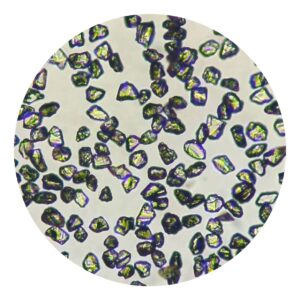

20-30 μm Diamond Micron Powder for High Removal and Heavy-Duty Metal Bond Cutting

SinoDiam – Industrial Diamond Micron For Consistent Quality and Repeatable Output.The 20-30 μm diamond micron range is designed for applications where high removal rates and process stability under heavy-duty conditions are critical. This size window enables predictable material removal while minimizing the risk of unexpected chipping or surface damage, providing reliable performance across demanding industrial processes.</p >Typical applications include metal bond grinding wheels, heavy ceramic removal, rough optical glass machining, PCBN/cermet binder sintering, and SiC wafer rough wire sawing. Both mono-crystalline and poly-crystalline grades are available, allowing precise selection based on material hardness, bond type, and process parameters to ensure consistent output.</p >Selecting the 20-30 μm range provides a stable high-removal window suitable for aggressive cutting while maintaining control over process variability. Compared to coarser grades above 30 μm, this range balances efficiency and reliability, making it the preferred choice for heavy-duty industrial machining applications.</p >

Comparison Table

| Micron Range | Removal Rate | Notes |

|---|---|---|

| <16 μm | Medium | Balanced, finishing bias |

| 20-30 μm | High | Stable heavy removal, controlled chipping |

| >30 μm | Extreme | Aggressive removal, higher crack risk |

Specification Table

| Property | Value |

|---|---|

| D50 Range | 20-30 μm |

| Shape | Mono / Poly available |

| Bond Compatibility | Metal bond optimized |

| Key Advantage | Stable processing window for heavy-duty removal, high mechanical impact tolerance |

[SinoDiam-Industrial-Diamond-Micron|20-30um|Process-Control|High-Removal|Mono-Poly|Japan-Korea Alignment]https://diamondmicron.com/product/micron-diamond-powder/