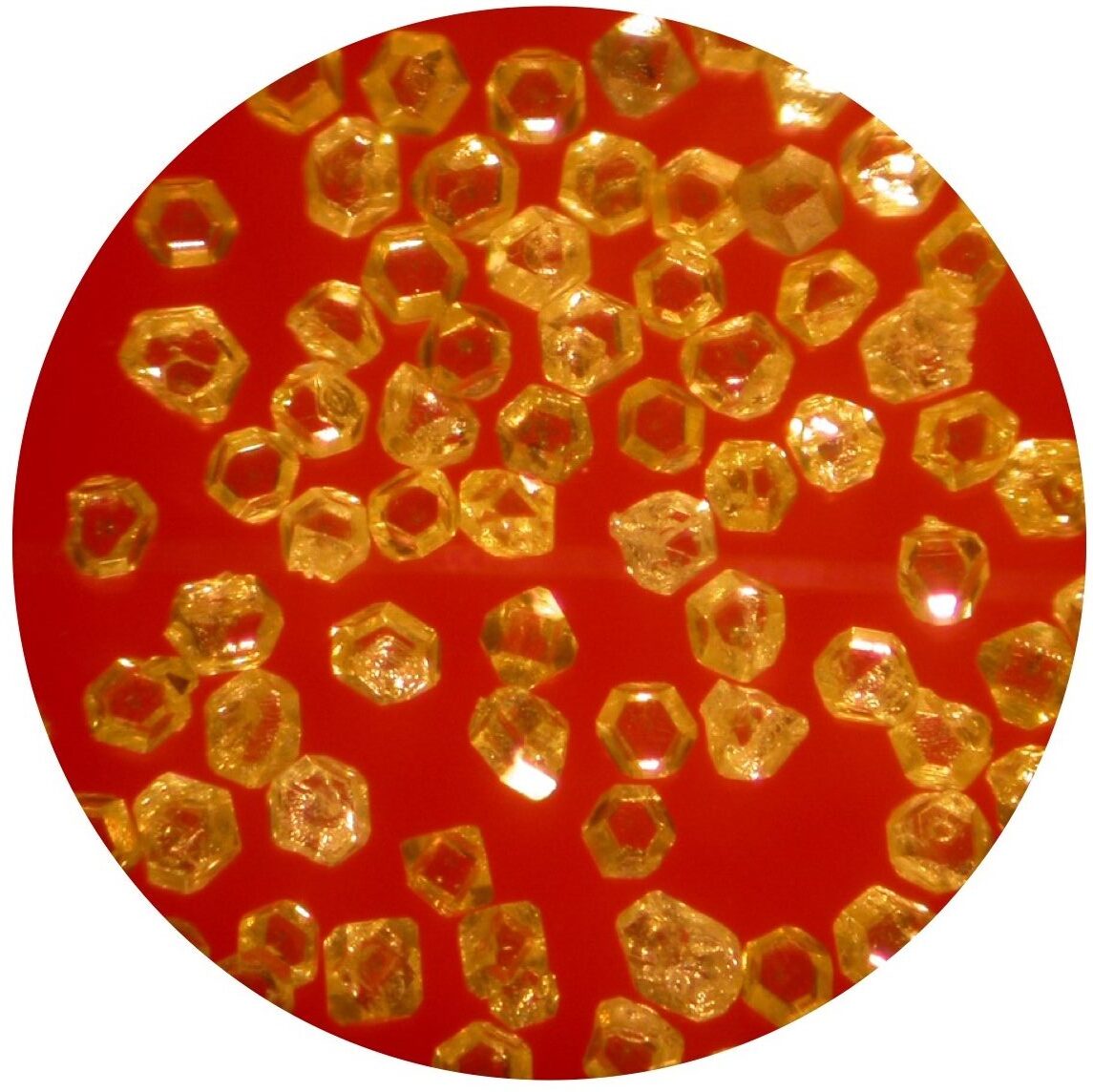

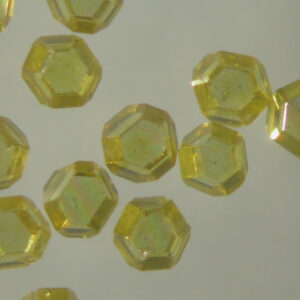

SND-G20 Fine-Size Metal Bond Synthetic Diamond Powder (Equiv. MBD4)

Description:

SND-G20 is crafted from high-purity synthetic diamond with ≥99.5% carbon content, offering a fine mix of angular and regular blocky crystals. Its medium-low toughness (Vickers hardness: 6,200–6,500 HV) and thermal stability (up to 750°C) make it ideal for metal bond diamond tools, providing superior grinding efficiency with minimal grit fracturing. This diamond powder delivers outstanding material removal rates (MRR), particularly for NA 6061 aluminum (used in construction framing) and EU mild steel (for automotive parts), outperforming generic MBD4 equivalents by 15% in terms of cutting speed and precision.

The blocky crystals enhance tool performance by reducing tool vibration, ensuring a clean surface finish on non-ferrous metals such as brass and copper. With a size tolerance of ±8%, SND-G20 delivers uniform bonding in metal bond tools, making it perfect for high-volume grinding applications.

Mesh Sizes Available:

- 80/100 (150–180μm), 100/120 (125–150μm), 120/140 (106–125μm)

- 140/170 (88–106μm), 170/200 (75–88μm), 200/230 (63–75μm)

- 230/270 (53–63μm), 270/325 (45–53μm), 325/400 (38–45μm)

Applications:

- Grinding aluminum (NA 6061/6063) for construction extrusions

- Grinding EU mild steel for automotive brackets and parts

- Polishing and grinding of non-ferrous metals (brass, copper)

- Ideal for medium-load grinding tasks in non-ferrous metal processing and mild steel grinding.

Key Features and Benefits:

- High Wear Resistance: With medium-low toughness, SND-G20 balances abrasion resistance and cutting efficiency for longer tool life in metal bond applications.

- Fast Material Removal: 15% faster MRR for aluminum and mild steel, compared to generic MBD4 products.

- Low Vibration Grinding: 65–70% crystal uniformity minimizes tool vibration, reducing surface defects on processed materials.

- Cost-Effective: 15–20% more cost-effective than SND-G30, providing better value for high-volume, low-moderate load grinding.

FAQ:

Q1: What materials is SND-G20 best for grinding?

A: SND-G20 is optimal for low to moderate hardness materials including NA 6061/6063 aluminum, EU mild steel, and non-ferrous metals like brass and copper. It is not suitable for extremely hard materials such as carbide or granite.

Q2: Is SND-G20 compatible with standard metal bond systems?

A: Yes, SND-G20 works seamlessly with NA/EU standard metal bond systems (e.g., bronze-copper, iron-copper alloys). Its clean crystal surface ensures strong bond adhesion, improving tool life and performance.

Q3: What is the advantage of SND-G20 over higher-toughness grades like SND-G30?

A: SND-G20 is more cost-effective than SND-G30, offering 15–20% better value for high-volume grinding applications. It delivers faster material removal rates (12–15 cm³/min) compared to SND-G30 (10–12 cm³/min), making it ideal for non-ferrous metal processing where extreme toughness isn’t needed.

Rezensionen

Es gibt noch keine Rezensionen.