CBN-A20 Amber Regular CBN – High-Toughness Multi-Bond CBN for Precision Ferrous Metal Grinding

Product Description

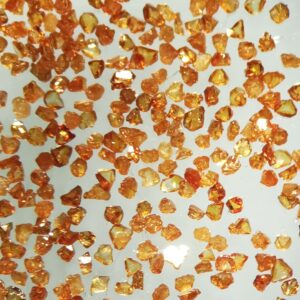

CBN-A20 combines uniform amber color and regular-shaped CBN crystals with tight particle size distribution, ensuring even dispersion and predictable grinding behavior across all major bond types.

Its high-toughness crystal structure resists micro-fracturing under heavy grinding forces (up to 40 N/cm²), maintaining sharpness and surface precision during extended use. Compared with generic CBN abrasives, CBN-A20 extends tool life by 25% and enables surface finishes as fine as Ra ≤1.2 μm—ideal for precision tool grinding and ferrous component finishing.

Unlike single-bond CBN products, CBN-A20 is engineered for full compatibility with vitrified, metal, and electroplated bonds, allowing manufacturers to streamline inventory while achieving consistent performance across multiple product lines.

Core Advantages

- 🔸 Multi-Bond Compatibility: Works seamlessly with vitrified, metal, and electroplated bonds, reducing the need for multiple CBN grades in production.

- 🔸 High-Toughness Structure: Withstands high grinding pressure and thermal stress, ensuring edge stability during aggressive cutting of ferrous alloys.

- 🔸 Precision Performance: Enables high-accuracy surface finishing (Ra ≤1.2 μm) in stainless steel and tool steel machining.

- 🔸 Extended Tool Life: Lasts up to 25% longer than generic multi-bond CBNs, reducing wheel dressing frequency and total tooling costs.

- 🔸 Global Versatility: Suitable for industrial-scale manufacturing and precision workshop applications, fully meeting international quality standards.

Technical Specifications

| Item | Details |

|---|---|

| Code No. | CBN-A20 |

| Color | Amber |

| Crystal Shape | Regular |

| Toughness | High |

| Available Mesh Sizes | 50/60–325/400 mesh |

| Bond Compatibility | Vitrified bond, Metal bond, Electroplated bond |

| Target Materials | Ferrous metals, Alloy steel, Stainless steel, Tool steel |

| Recommended Grinding Pressure | ≤ 40 N/cm² |

| Surface Finish (Ra) | ≤ 1.2 μm |

| Durability Improvement | +25% vs. generic CBN |

FAQ

Q1: What makes CBN-A20 suitable for electroplated tools?

A: Its regular crystal structure ensures strong mechanical anchoring in nickel electroplated coatings, preventing grit loss and ensuring high precision in ferrous part shaping such as tool steel dies.

Q2: Can CBN-A20 handle high-speed grinding?

A: Yes. With its high-toughness structure, CBN-A20 supports high-speed grinding up to 6,000 RPM, commonly used in industrial machining of stainless steel and alloy components.

Q3: Which mesh sizes of CBN-A20 are best for vitrified bond wheels?

A: 120/140 to 230/270 mesh are optimal—small enough for precision surface finishing (Ra ≤1.2 μm) while maintaining efficient cutting power and bond retention.

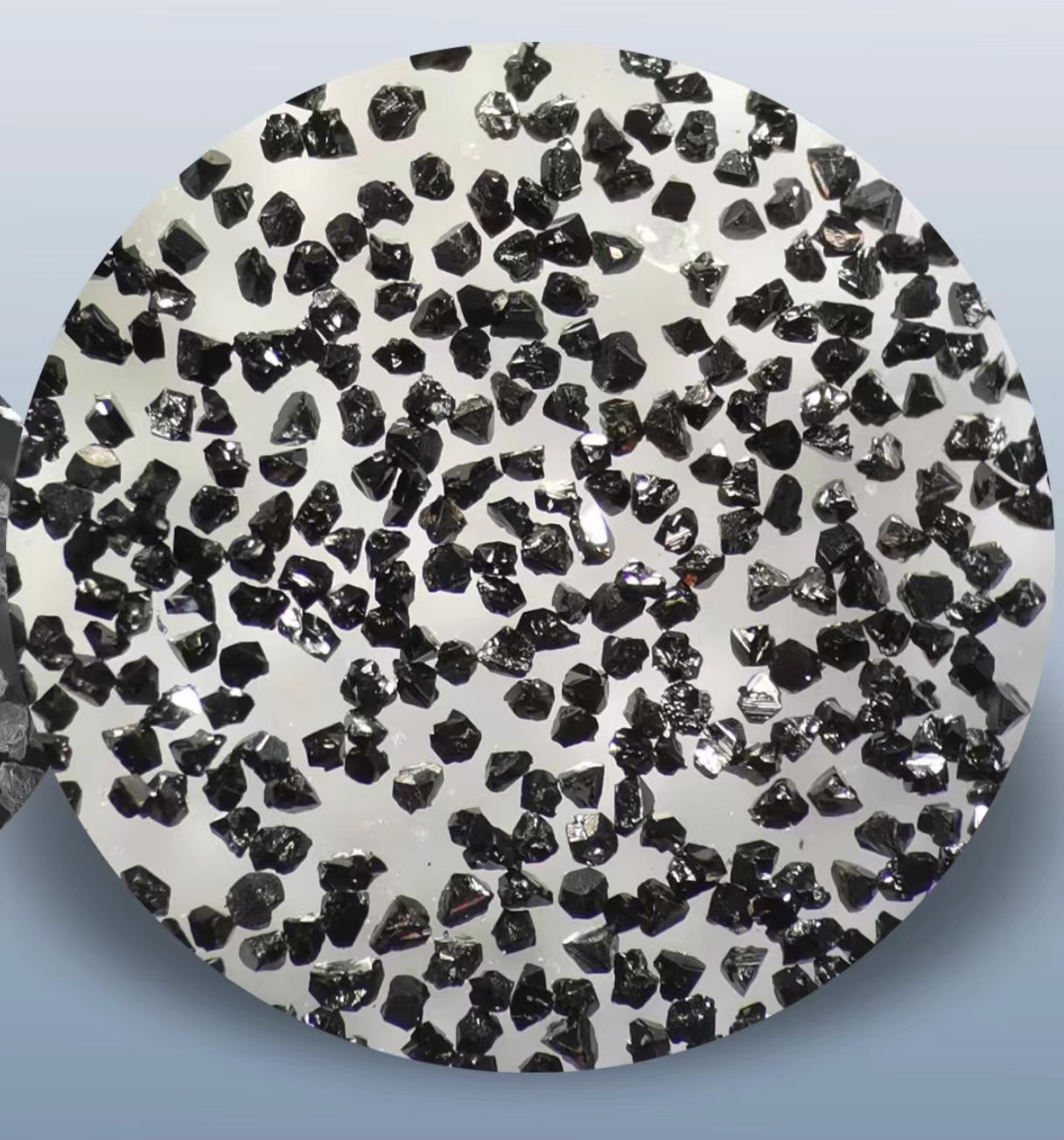

CBN-B20 Bright Black Blocky CBN – High-Temp / High-Speed Grinding Expert

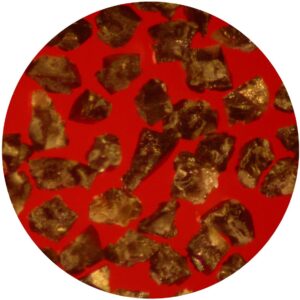

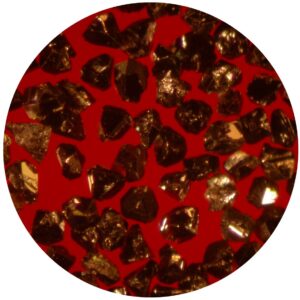

CBN-A10 Amber Irregular CBN (50/60–325/400 Mesh) – Resin Bond CBN for Ferrous Metal Grinding

Rezensionen

Es gibt noch keine Rezensionen.